Device for producing foil rolls

A technology of film rolls and equipment, applied in thin material handling, strip winding, transportation and packaging, etc., can solve problems such as increasing production costs and having to be removed from the machine by hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

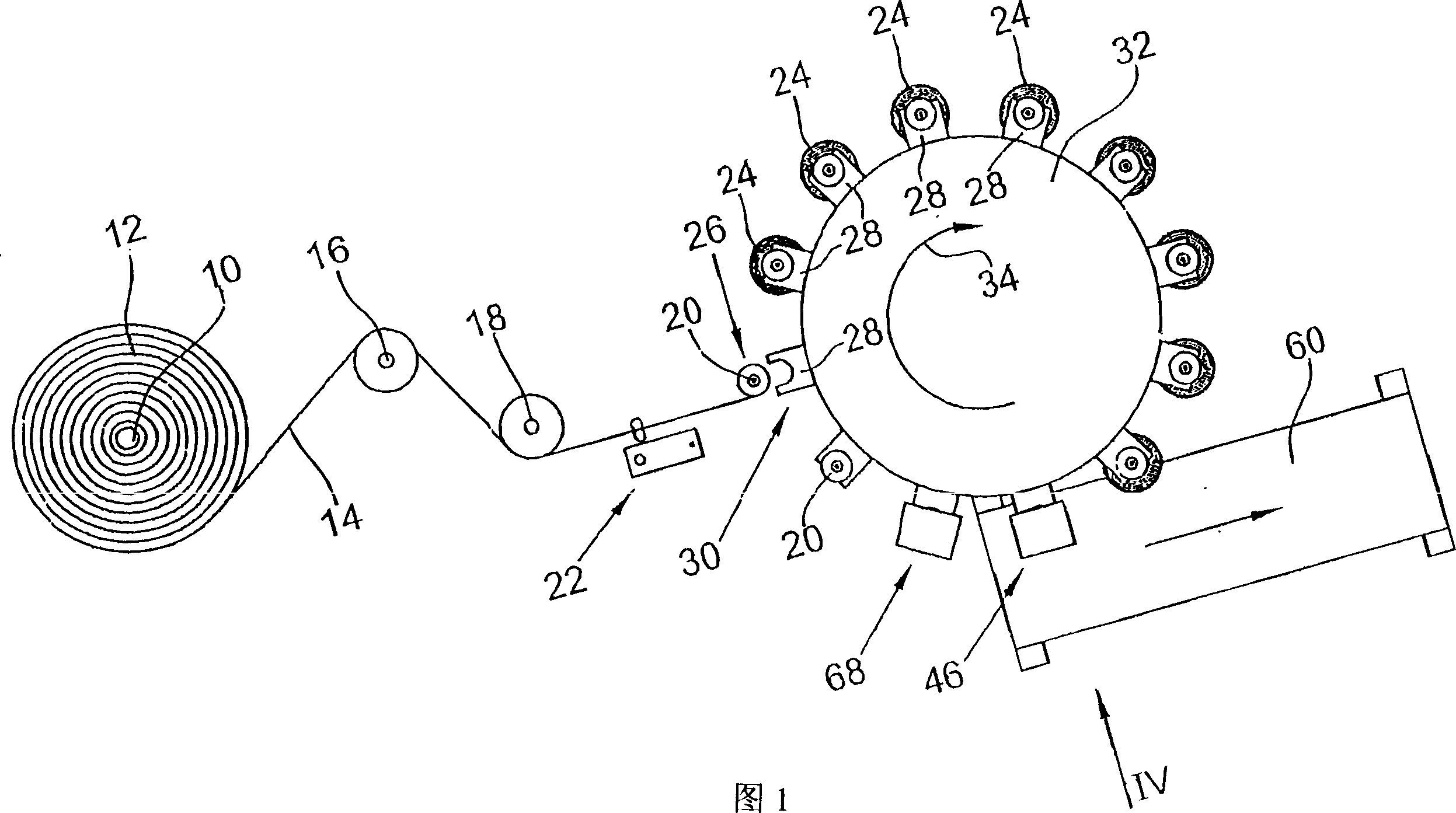

[0024] According to the basic structure shown in FIG. 1 , the apparatus according to the invention for producing film rolls comprises a roll holder 10 . The roll holder 10 carries a film roll 12 having a generally non-stretched film. The film web 14 is unrolled from the film roll 12 and guided on deflection wheels 16 , 18 . Typically, these devices comprise a plurality of wheels 16, 18 connected in part to drive means, wherein the rate of rotation of each wheel 16, 18 can be varied. The film sheet 14 can thus be stretched. In particular, one or more of the wheels 16 , 18 may be embossed for facilitating stretching of the film roll 14 .

[0025] The film web 14 is wound onto a winding mandrel 20 after passing deflection rollers 16 , 18 . After a film web 14 of predetermined length has been wound onto a winding mandrel 20, the film web 14 is severed with the aid of a cutting device 22 comprising, for example, a knife.

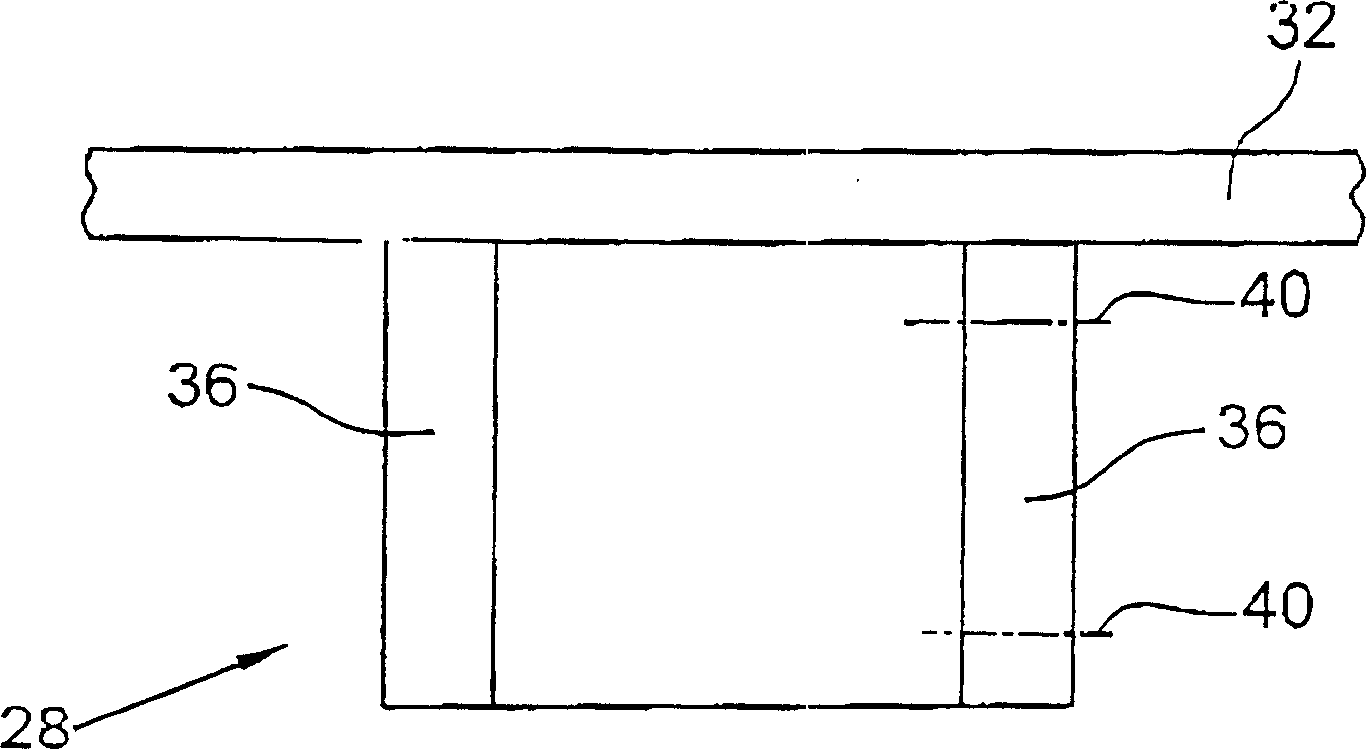

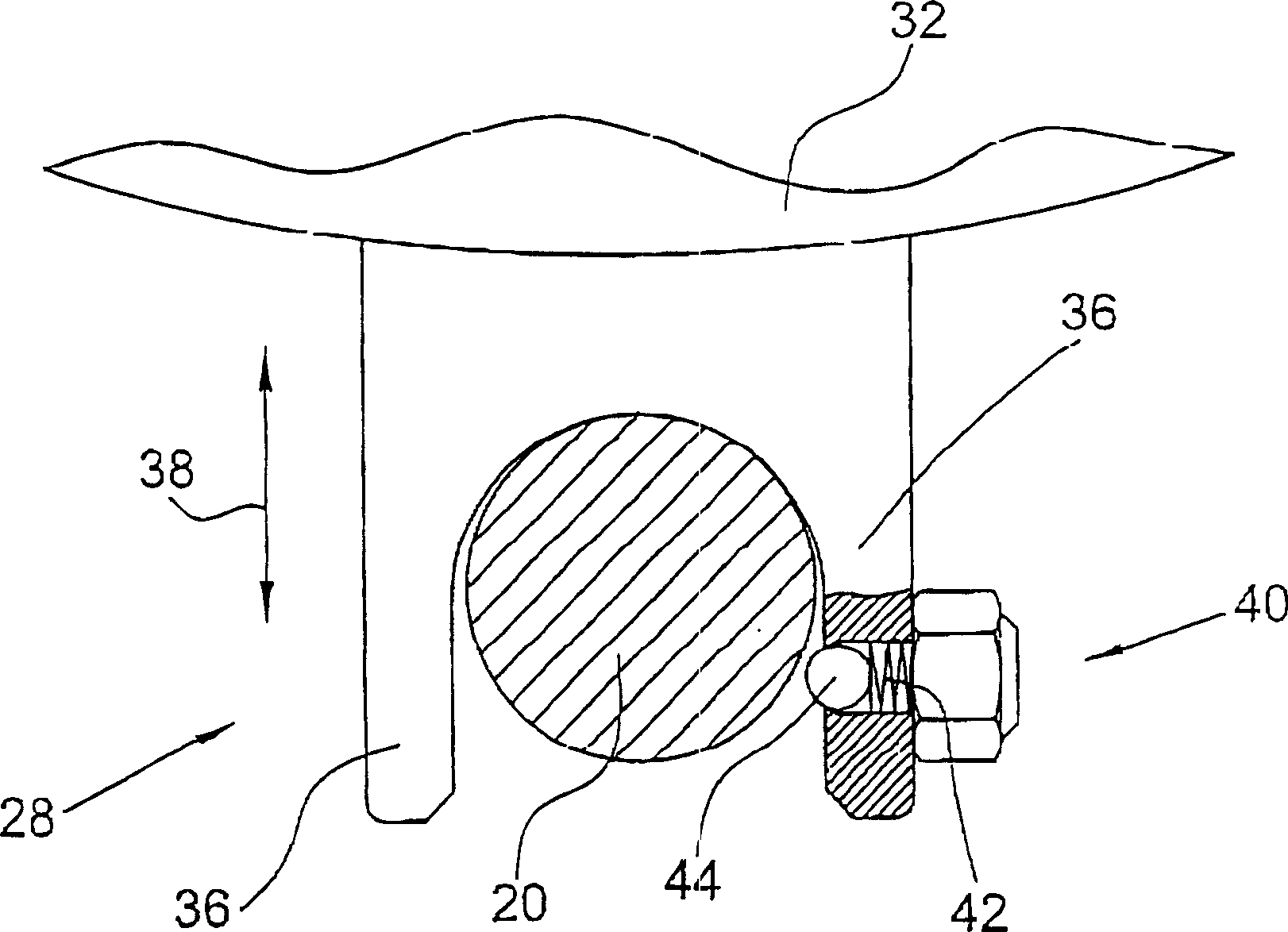

[0026] In the illustrated embodiment, the winding mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com