Method for producing an inner ring for a tapered roller bearing, and tapered roller bearing having an inner ring

A technology of tapered roller bearings and tapered rollers, applied in the direction of roller bearings, rolling contact bearings, bearings, etc., can solve complex problems and achieve the effect of minimizing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

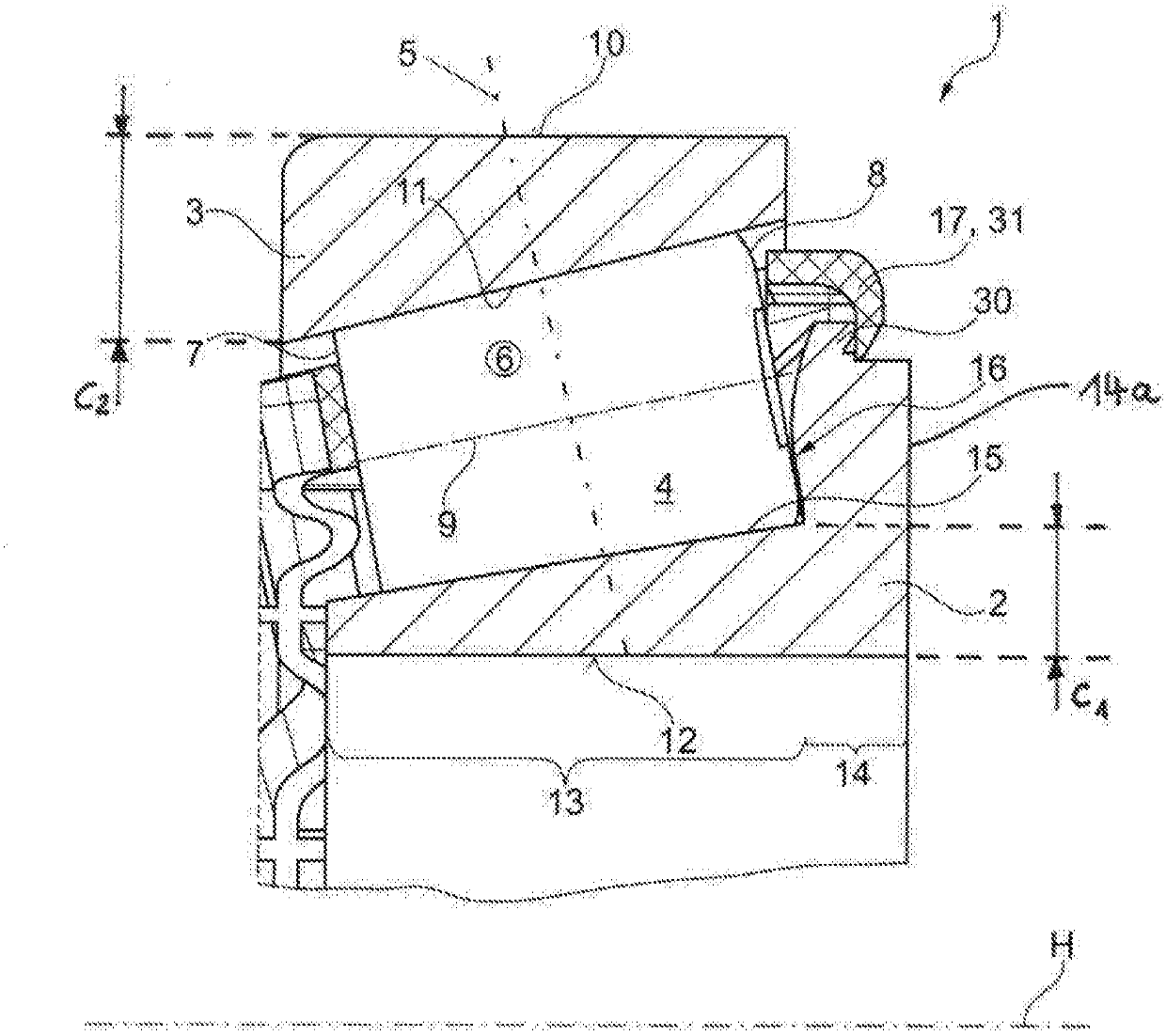

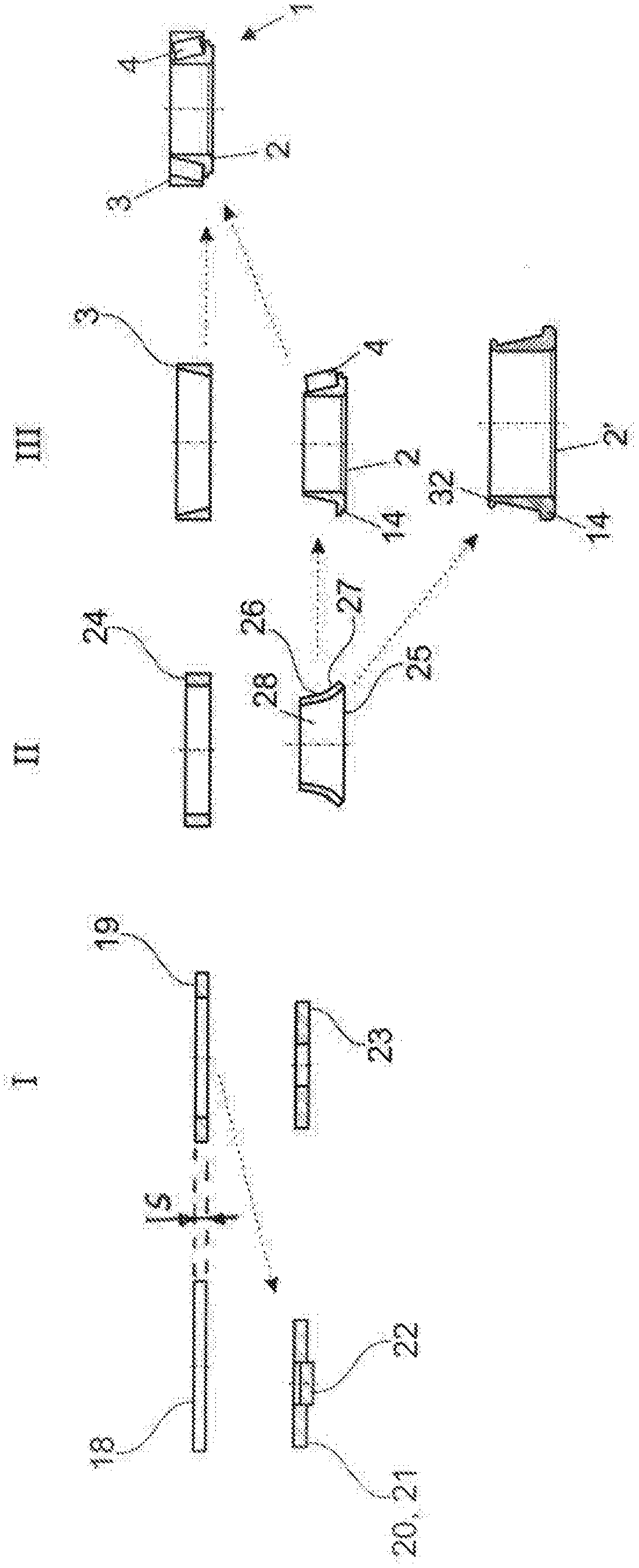

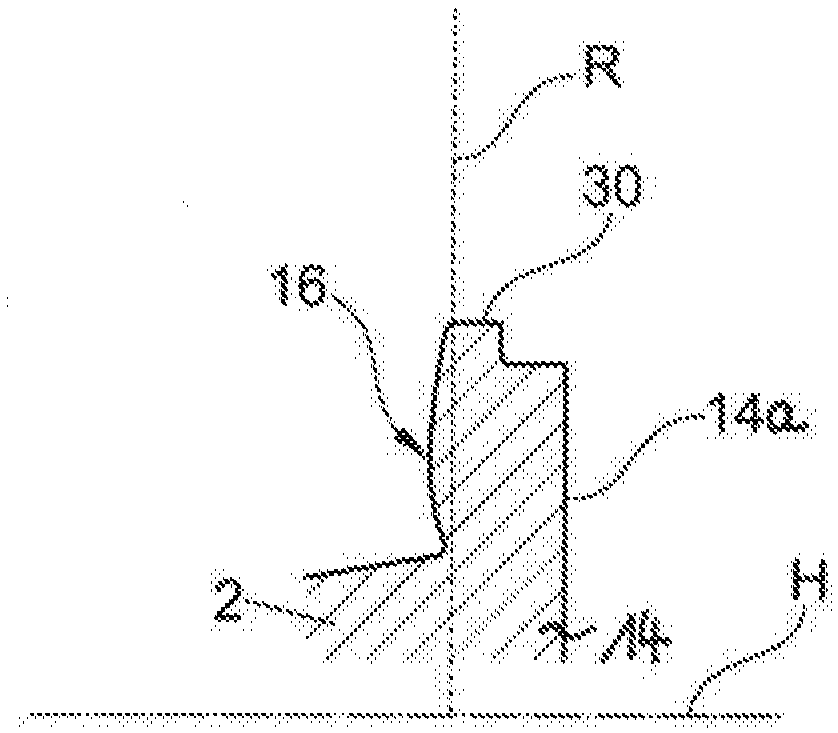

[0032] figure 1 A tapered roller bearing 1 as an exemplary embodiment of the invention is shown along the main axis of rotation H in a schematic longitudinal half-section. The tapered roller bearing 1 has an inner ring 2 , an outer ring 3 and a plurality of tapered rollers 4 arranged between the inner ring 2 and the outer ring 3 in a rolling manner. The tapered roller bearing 1 is configured as a single-row tapered roller bearing. The tapered roller bearing 1 is designed in particular as a radial rolling bearing, wherein the pressure angle 5 is between 0 and 45 degrees.

[0033] The tapered roller 4 has a frustoconical shape with a conically curved running surface 6 . Furthermore, the tapered rollers 4 each have a small end side 7 and a large end side 8 . The axis of rotation 9 of the tapered roller 4 is arranged obliquely relative to the main axis H of rotation.

[0034] The outer ring 3 has a cylindrical outer surface 10 and a conical inner raceway 11 oriented radially inw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com