Magnetic powder stirring device with feeding structure and processing method

A stirring device and processing method technology, applied in heating devices, chemical instruments and methods, mixers with rotating containers, etc., can solve problems that affect work efficiency, difficult to dismantle and clean, and do not have a feeding structure, so as to improve work efficiency. Efficiency, improve drying efficiency, improve creative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

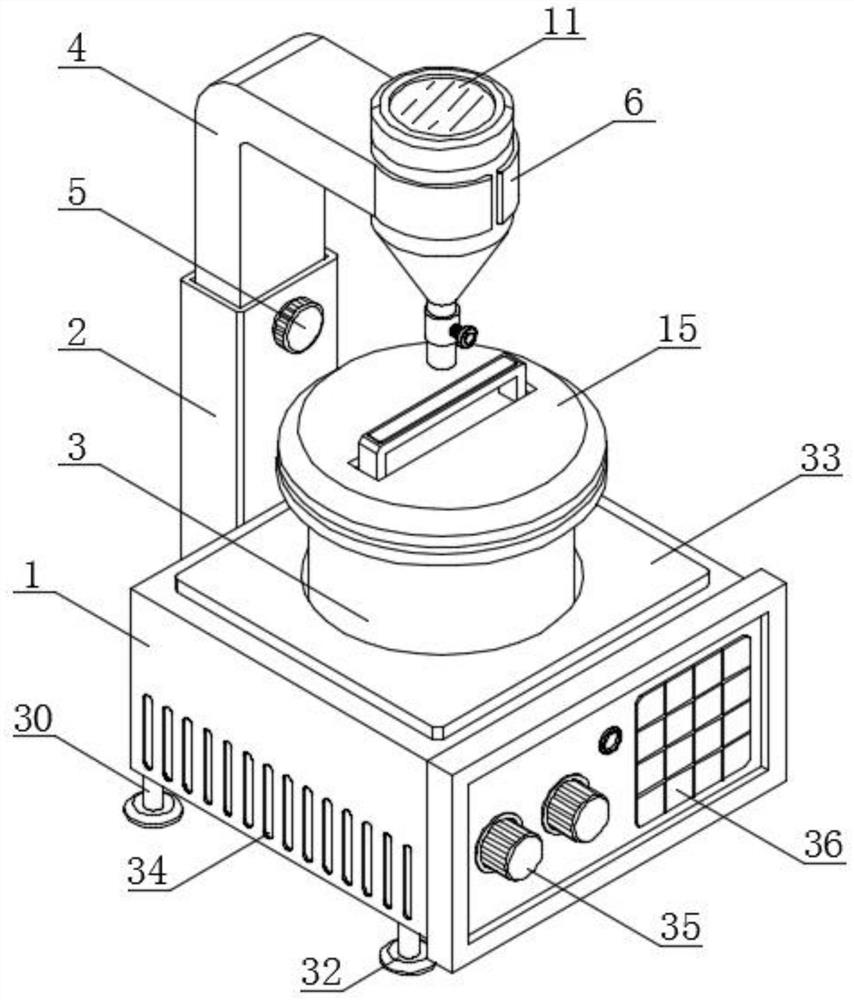

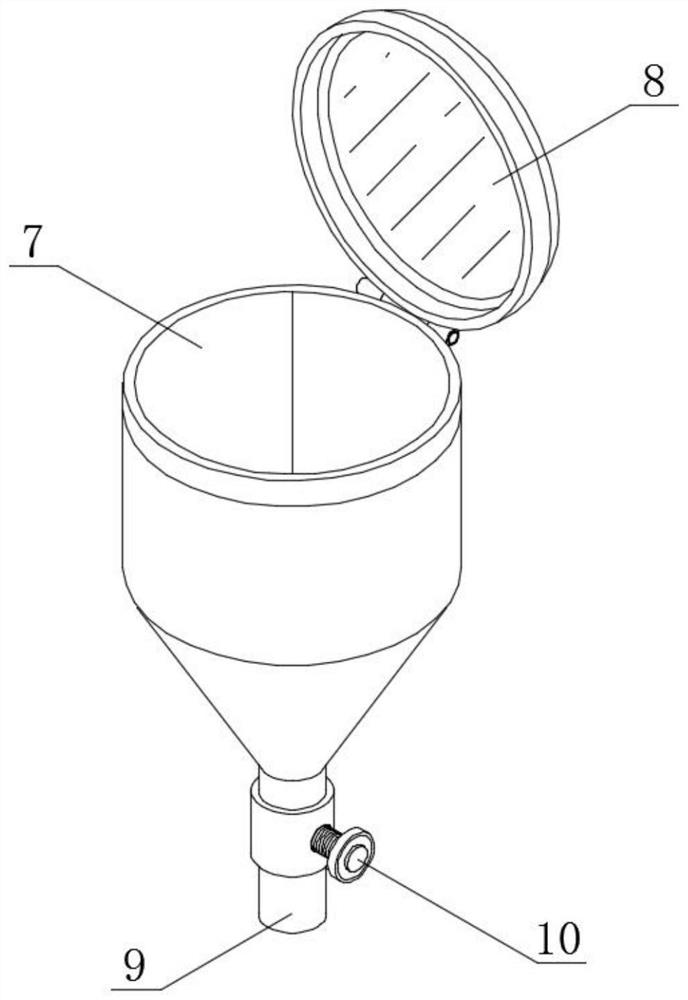

[0042] see figure 1 and image 3 , an embodiment provided by the present invention: a magnetic powder stirring device with a feeding structure and a processing method, including a working box 1, a supporting sleeve 2 and an outer barrel 3, and a supporting sleeve is installed in the middle of the back of the working box 1 2. The middle part of the top of the working box 1 is provided with an outer barrel 3; the inside of the support sleeve 2 is slidingly connected with an adjustment frame 4, and the intersection of the adjustment frame 4 and the support sleeve 2 is threadedly connected with a fastening knob 5; the adjustment frame 4 A fixing clip 6 is installed on the top of the fixing clip 6, and a feeding tube 7 is arranged inside the fixing clip 6, and a switch cover 8 is connected to one side of the top of the feeding tube 7, and a discharge pipe 9 is installed in the middle of the bottom of the feeding tube 7, and the outlet pipe 9 The surface is provided with a control ...

Embodiment 2

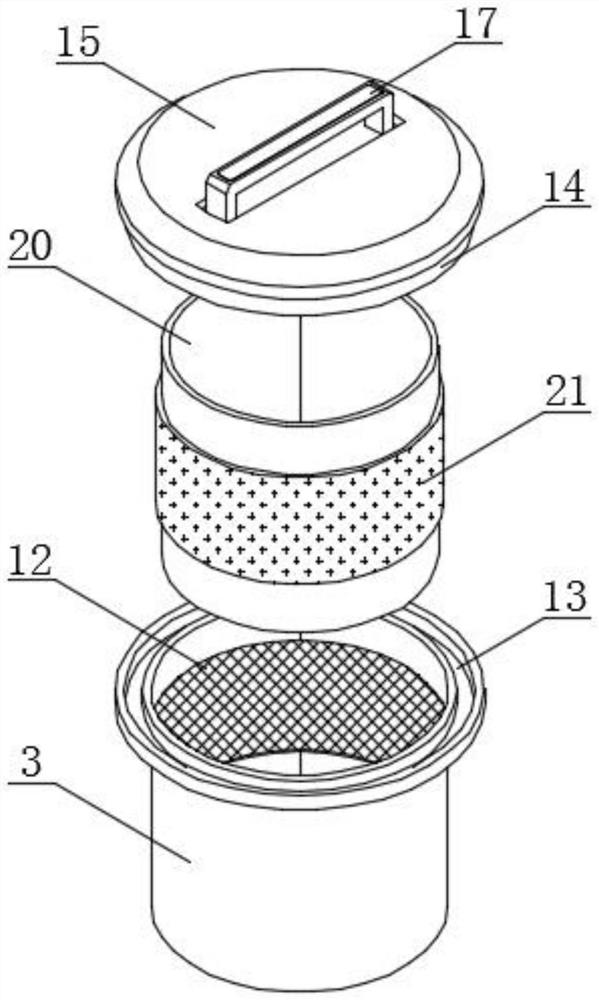

[0045] see Figure 4 and Figure 5 , an embodiment provided by the present invention: a magnetic powder stirring device and processing method with a feeding structure, including an outer barrel 3, a heater assembly 18 and a heating lamp assembly 16, and the middle part of the inner wall of the outer barrel 3 is provided with a The inside of the air outlet and the air outlet is provided with a filter screen 12, and the middle part of the top of the outer barrel 3 is provided with a limit slot 13, and the inside of the limit slot 13 is plugged with a limit plate 14, and the inside of the limit slot 13 passes through the limit Plate 14 is plugged with bung 15, and the inner top wall of bung 15 is equipped with heating lamp assembly 16, and the middle part of bung 15 tops offers limit groove, and the inside of limit groove is equipped with handle 17, and working box 1 inside The two sides of heater assembly 18 are installed, and the position of heater assembly 18 is adapted with ...

Embodiment 3

[0048] see Figure 6 , Figure 7 and Figure 8 , an embodiment provided by the present invention: a magnetic powder stirring device with a feeding structure and a processing method, including a driving motor 31, a fixed disc 25 and a fixed latch 27, and the surface of the mixing bucket 20 is provided with an insulating layer 21 , the top of the inner wall of the outer barrel 3 is equipped with a fixed rod 22, the top of the fixed rod 22 is connected with a non-magnetic conductive steel sheet 23, and the intersection of the fixed rod 22 and the non-magnetic conductive steel sheet 23 is threadedly connected with a fastening bolt 24, and Non-magnetic conductive steel sheet 23 is respectively positioned at the both sides of mixing bucket 20 inside, and the middle part of working box 1 inside is equipped with driving motor 31, and the output end of driving motor 31 is equipped with fixed disc 25, and the middle part of fixed disc 25 top is provided with Anti-slip layer 26, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com