Phosphorescent metallo complexes and organic electrophosphorescent device prepared by electrochemical deposition

A technology of metal complexes and phosphorescent devices, applied in the application of organic electrophosphorescent devices, phosphorescent metal complexes, light-emitting layer thin films, can solve the problems of complex manufacturing process, high equipment cost, high equipment and raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1: Phosphorescent metal ruthenium complex Ru(bpy) containing electroactive groups 2 (tkdpbpy)(AsF 6 ) 2 Synthesis

[0082]

[0083] synthetic route

[0084]

[0085] 1. Synthesis of (3,5-di-(hexyloxy-6-(N-carbazole))-phenylmethanol

[0086] 422.7mg (3mmol) 3,5-dihydroxyl-phenylcarbinol, 2g (6mmol) N-(6-bromo-hexane)-carbazole, 81.2mg (0.3mmol) 18-crown-6, 916.8mg (6.6 mmol) potassium carbonate was reacted in 50ml acetone solvent for 40 hours. The resulting liquid was extracted with dichloromethane, and the organic phase was separated by a column using dichloromethane as the eluent to obtain a colorless oily liquid product with a yield of 84%. of the compound 1 H NMR is as follows: 1 H NMR (500MHz, CDCl 3 ): δ8.11-8.09 (d, 4H, Ar-H-car), δ7.47-7.44 (t, 4H, Ar-H-car), δ7.41-7.39 (d, 2H, Ar-H- car), δ7.47-7.44(t, 4H, Ar-H-car), δ6.46(s, 2H, Ar-H), δ6.32-6.31(s, 1H, Ar-H), δ4. 60(s, 2H, CH 2 ), δ4.33-4.30 (t, 4H, CH 2 ), δ3.90-3.87 (t, 4H, CH 2 ),...

Embodiment 2

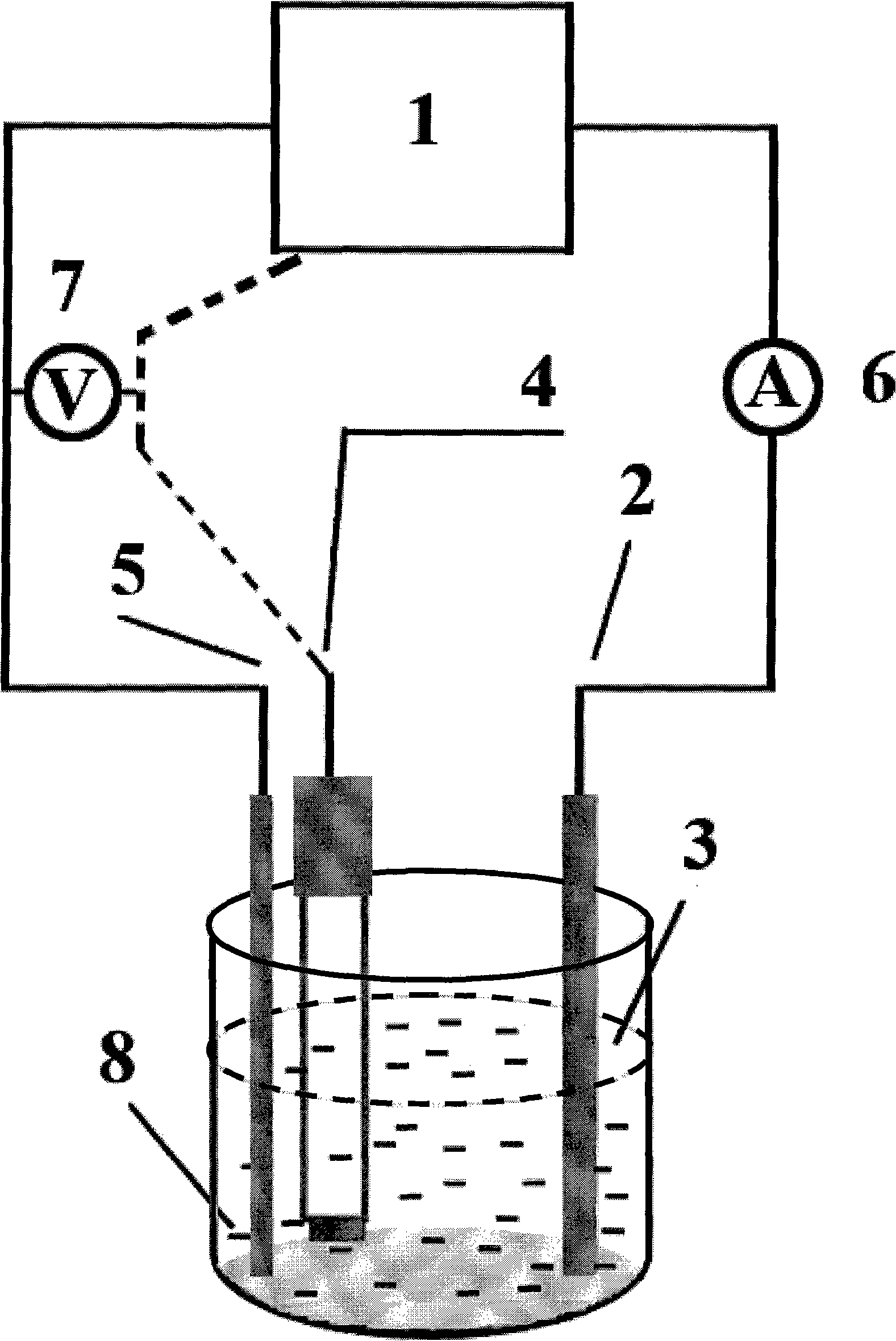

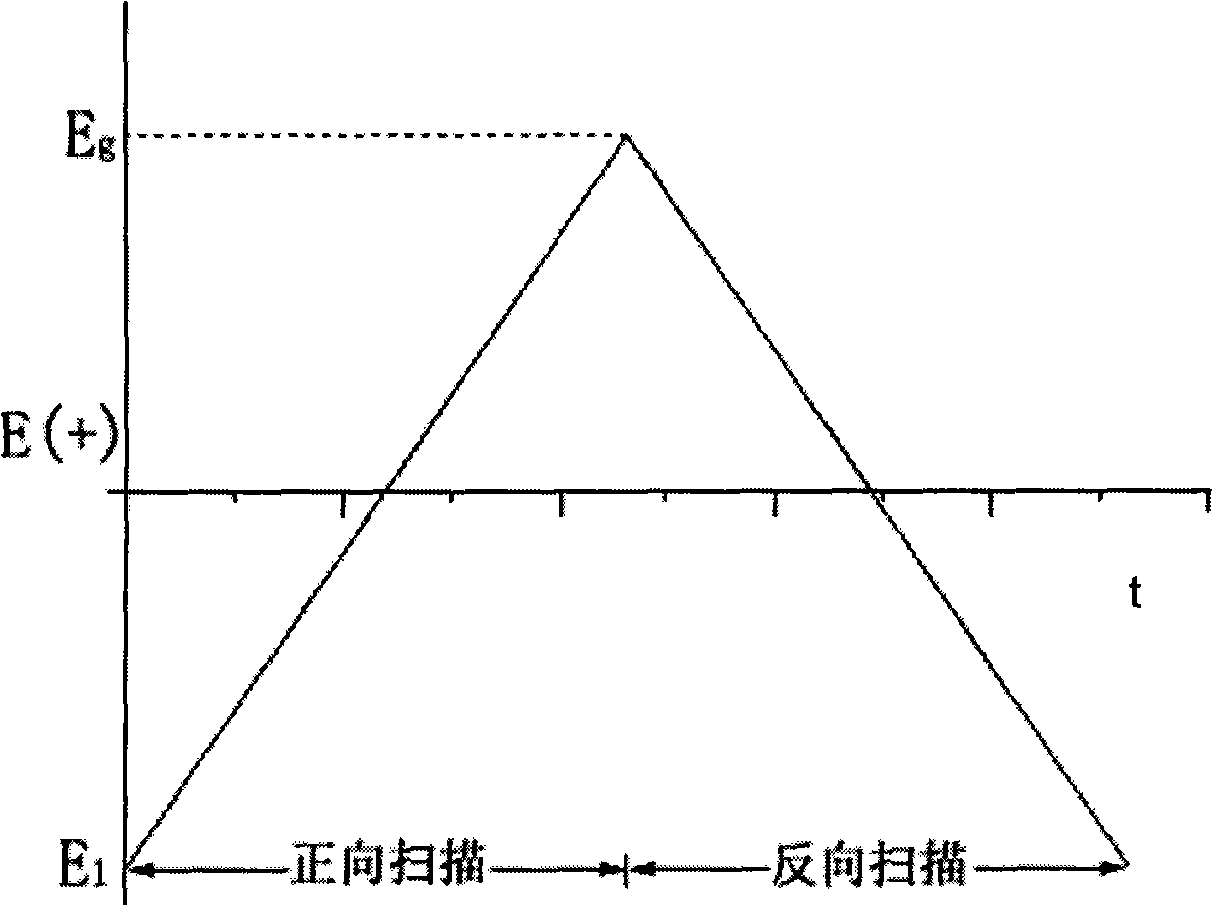

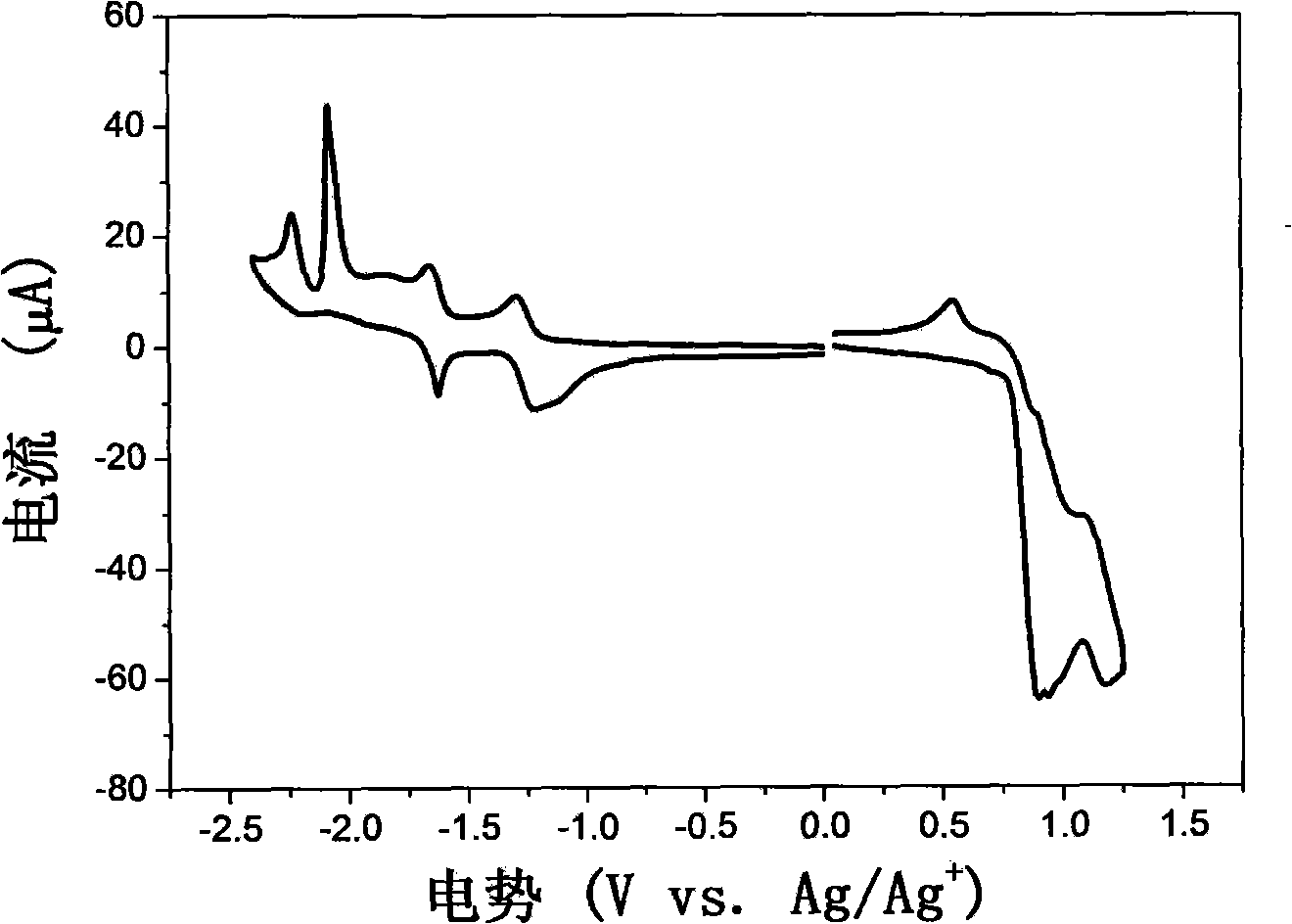

[0094] Example 2: Electrochemical preparation of luminescent film

[0095] 1. Preparation of supporting electrolyte solution

[0096] (4,4'-dicarboxylic acid-(3,5-bis-(hexyloxy-6-(N-carbazole)))-phenylmethyl ester bipyridine)-bipyridine ruthenium hexa Fluoroarsenate is used as the guest material, and TCPC is used as the host material (the material structure is shown in the following formula, and its synthesis method is referred to Chinese patent: 200610016555.0, "Preparation of organic light-emitting thin films by electrochemical deposition and its application in electroluminescent devices"). The two are dissolved together in the electrolyte solution, the mass ratio of the guest material to the host material is 20%:80%, the concentration of TCPC in the electrolyte solution is 1 mg / ml, and the supporting electrolyte is tetrabutylammonium hexafluorophosphate with a concentration of 0.1 mol / liter, the electrolytic solvent is a mixed solution of acetonitrile and dichloromethane, ...

Embodiment 3

[0108] Example 3: Preparation of high-efficiency electroluminescent devices using electropolymerized thin films

[0109] 1. Fabrication of multilayer electroluminescent devices

[0110] In order to obtain high-efficiency devices, we use vacuum evaporation of electron transport and hole blocking materials on the electrochemically deposited film to balance the ratio of electrons and holes, increase the recombination probability of carriers in phosphorescent molecules, and improve luminescence efficiency. The specific embodiment is as follows: the cleaned electrochemically deposited film is dried under vacuum condition for 1 hour at a temperature of 25°C. Obtain the dry film under vacuum condition, vapor-deposit 2,9-dimethyl-4,7-diphenylphenanthroline (BCP) as the hole blocking layer of electroluminescent device, the thickness of vapor-deposited BCP is 50nm . Then vapor-deposit three (8-hydroxyquinoline) aluminum (Alq 3 ) as the electron transport layer of the electroluminesc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com