Anti-mosquito wallpaper and preparation method thereof

An anti-mosquito and wallpaper technology, applied in the field of wallpaper, can solve problems such as difficult to exert the efficacy of medicine, short-term anti-mosquito effect, and easy to be dispersed by wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

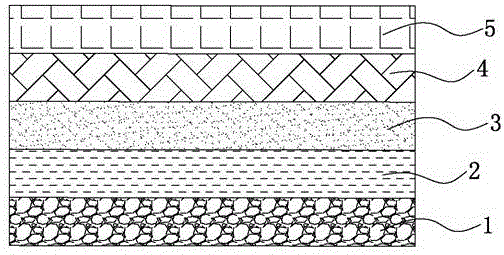

[0054]A kind of anti-mosquito wallpaper, comprising substrate layer 1, resin layer 2, ink layer 3, anti-mosquito adhesion layer 4 and waterproof breathable layer 5 successively from bottom to top, described substrate layer 1 selects non-woven paper, and described resin layer 2 is composed of film-forming substances, additives, and solvents in a weight fraction of 100:1:2; the ink layer 3 is composed of 100 parts of acrylic resin liquid, 20 parts of water-based color paste, 20 parts of color masterbatch, 8 parts of mica powder, gold 3 parts of green onion powder are made by stirring and mixing;

[0055] The anti-mosquito adhesion layer 4 includes the following raw materials in parts by mass: 40 parts of water-based film-forming resin emulsion, 12 parts of mosquito repellent microcapsules, 20 parts of aluminum silicate, 8 parts of thickener, 2.5 parts of wetting and dispersing agent, fluid 2.5 parts of leveling agents, 1.5 parts of defoamers, and 8 parts of water; the preparatio...

Embodiment 2

[0069] The difference from Example 1 is that: the base material layer 1 is made of cotton and linen chemical fiber fabric, the resin layer 2 is composed of film-forming substances, auxiliary agents, and solvents in a weight fraction of 100:0.1:10; the ink layer 3 It is made by stirring and mixing 100 parts of acrylic resin liquid, 25 parts of water-based color paste, 30 parts of color masterbatch, 10 parts of mica powder, and 5 parts of glitter powder; the anti-mosquito adhesion layer 4 includes the following raw materials in parts by mass: water-based 30 parts of film-forming resin emulsion, 5 parts of mosquito repellent microcapsules, 60 parts of aluminum silicate, 10 parts of thickener, 0.5 parts of wetting and dispersing agent, 2 parts of leveling agent, 1 part of defoamer, and 10 parts of water; The mosquito repelling microcapsules are prepared by stirring and mixing permethrin, litsea cubeba oil and lavender oil at a mass-to-number ratio of 5:2.5:1;

[0070] The preparat...

Embodiment 3

[0083] The difference from Example 1 is that: the substrate layer 1 is coated paper, the resin layer 2 is composed of film-forming substances, auxiliary agents, and solvents in a weight fraction of 100:2:1; the ink layer 3 is composed of 100 parts of acrylic resin liquid, 20 parts of water-based color paste, 10 parts of color masterbatch, 1 part of mica powder, and 2 parts of glitter powder are prepared by stirring and mixing; the anti-mosquito adhesion layer 4 includes the following raw materials in parts by mass: water-based composition 100 parts of film resin emulsion, 20 parts of mosquito repellent microcapsules, 20 parts of aluminum silicate, 2 parts of thickener, 2.5 parts of wetting and dispersing agent, 5 parts of leveling agent, 1.5 parts of defoamer, 8 parts of water; Mosquito repellent microcapsules are made by stirring and mixing permethrin, litsea cubeba oil, and lavender oil in a mass-to-number ratio of 4:2:1;

[0084] The preparation process of the anti-mosquito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com