Preparation method of anti-pollution reverse osmosis composite membrane, and reverse osmosis composite membrane

A reverse osmosis composite membrane, anti-pollution technology, applied in the field of composite membranes, can solve problems such as shortening the service life of the membrane, achieve low equipment operation requirements, improve service life, and achieve the effects of scale and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

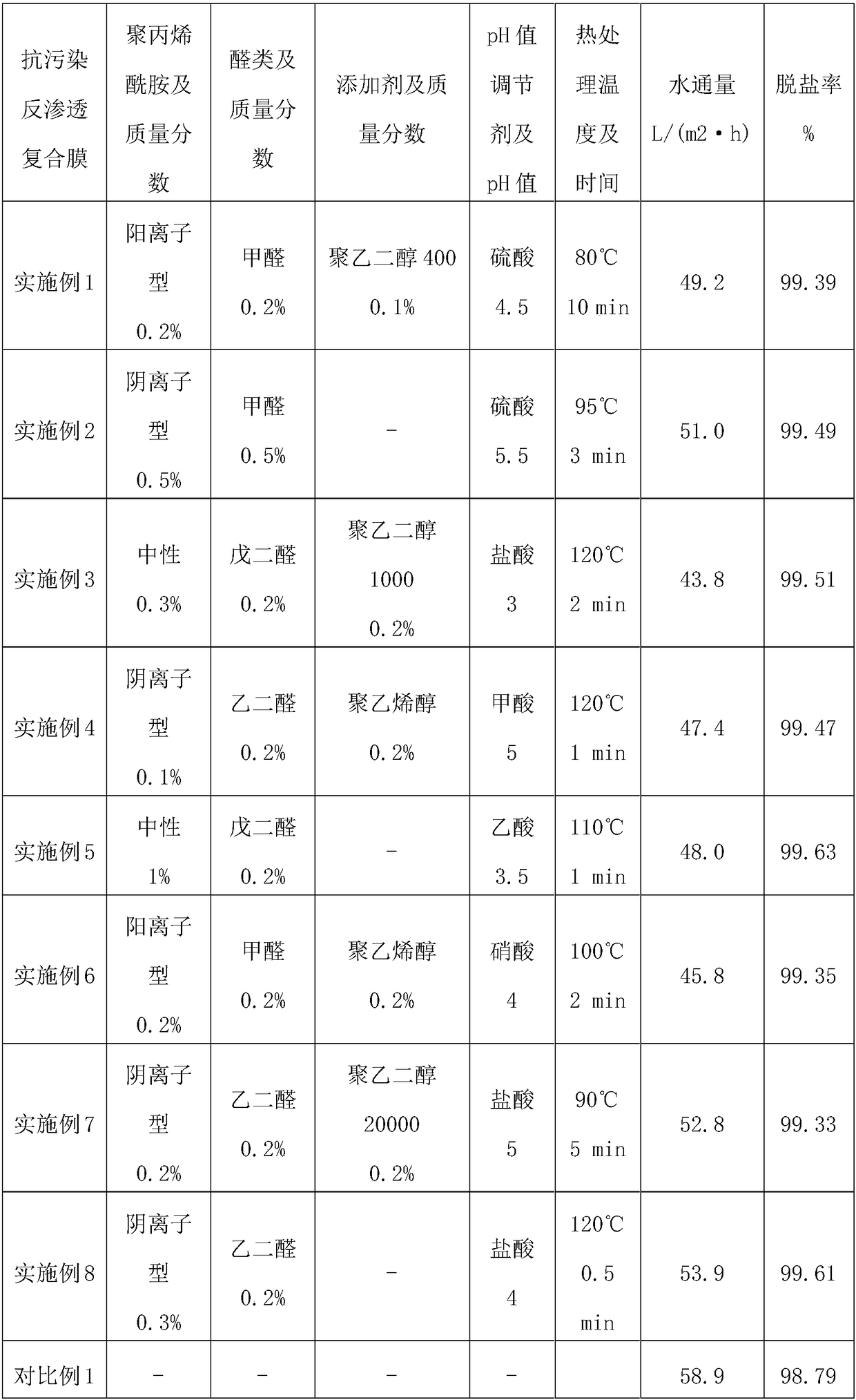

[0021] The embodiment discloses a preferred preparation method of reverse osmosis composite membrane and the anti-pollution reverse osmosis composite membrane prepared by the method. The specific operation steps of the preparation method are as follows:

[0022] Step 1: Preparation of polysulfone support membrane:

[0023] The polysulfone support membrane can be prepared by existing techniques. Polysulfone (PSf) and additives are dissolved in a solvent to prepare a casting solution; then filtered, defoamed, and then cast on a non-woven fabric; then immersed in deionized water to gel, thereby making a polysulfone support membrane.

[0024] Among them: the additives are polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), ethylene glycol monomethyl ether (EGME), sodium dodecylbenzenesulfonate (SDBS), sodium dodecylsulfonate ( One or more of SDS); solvents are N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), N-methylpyrrolidone (NMP), dimethyl One or several kinds o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com