Calixarene amide derivative stationary phase and preparation method and application thereof

An aromatic hydrocarbon amide and derivative technology, which is applied in the field of a calixarene amide derivative stationary phase and its preparation, can solve the problems of low separation efficiency and low separation purity, and achieves a simple preparation method, good application prospect and high bonding amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

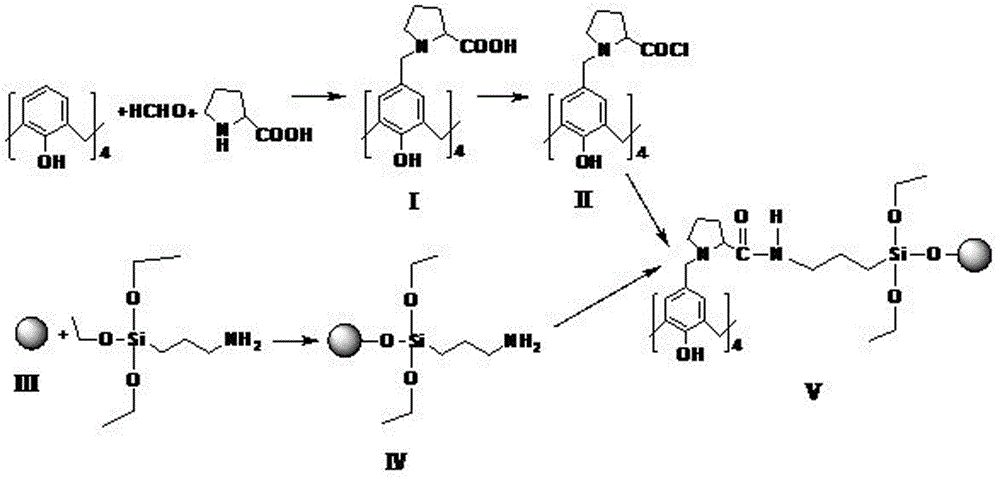

[0024] like figure 1 As shown, the stationary phase of a calixarene amide derivative provided in this example includes a calixarene group, a proline group and an aminopropyltriethoxy bonded silica gel group, and its structural formula is shown in the following formula, The spheres represent the activated silica chains:

[0025] .

[0026] The calixarene amide derivative stationary phase described in this embodiment can be passed such as figure 2 Shown reaction process obtains, and concrete preparation process comprises the following steps:

[0027] Synthesis of calixarene proline derivatives (I): Take 0.8g of de-tert-butylcalixarene in a 50mL round bottom flask, add 20mL of tetrahydrofuran solution under magnetic stirring, then add 1g of L-proline, 2mL of Glacial acetic acid and 1 mL of formaldehyde aqueous solution with a mass fraction of 37% were reacted at room temperature for 36 hours, filtered and washed 5 times with tetrahydrofuran, and the obtained solid was recry...

Embodiment 2

[0037] The calixarene amide derivative stationary phase provided in this example has the same structural formula as that in Example 1.

[0038] This embodiment also provides a preparation method for preparing the stationary phase of the calixarene amide derivative, the whole reaction process is as follows figure 2 As shown, the specific preparation process is roughly the same as the preparation steps in Example 1, except that:

[0039] In the synthesis step of calixarene proline derivatives (I), 1.5 g of de-tert-butyl calixarene dissolved in 40 mL of tetrahydrofuran solution and 5 g of L-proline, 3 mL of glacial acetic acid and 2 mL of mass percent are 30% aqueous formaldehyde solution was used for the reaction.

[0040] In the acid chlorination step of the calixarene proline derivative, 1.9 g of the calixarene proline derivative was reacted with 3 mL of oxalyl chloride in anhydrous dichloromethane.

[0041] In the preparation step of aminopropyltriethoxysilane-bonded silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com