Process for degrading cultivation waste water nitrite using immobilized nitrifying bacteria

A technology for nitrifying bacteria and nitrite, which is applied in the field of degrading nitrite in aquaculture wastewater, can solve problems such as difficulty in realization and energy consumption, and achieve the effects of reducing cost, low cost and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

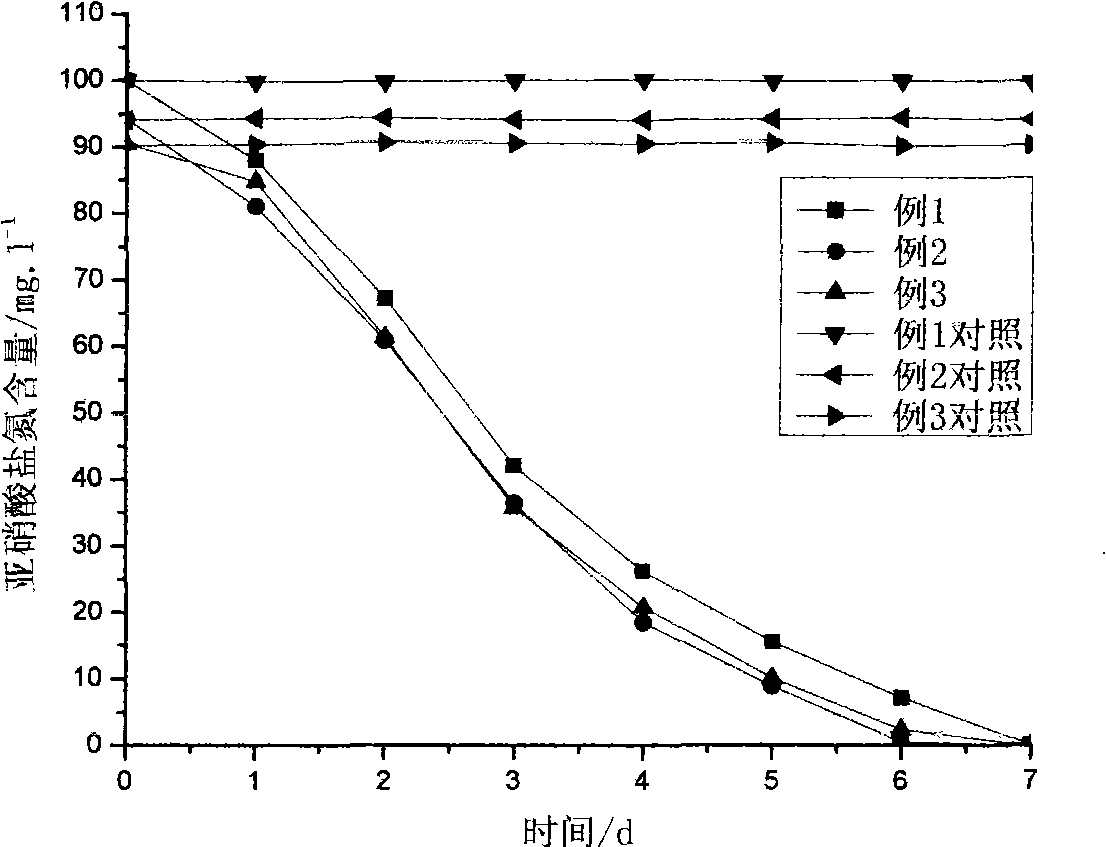

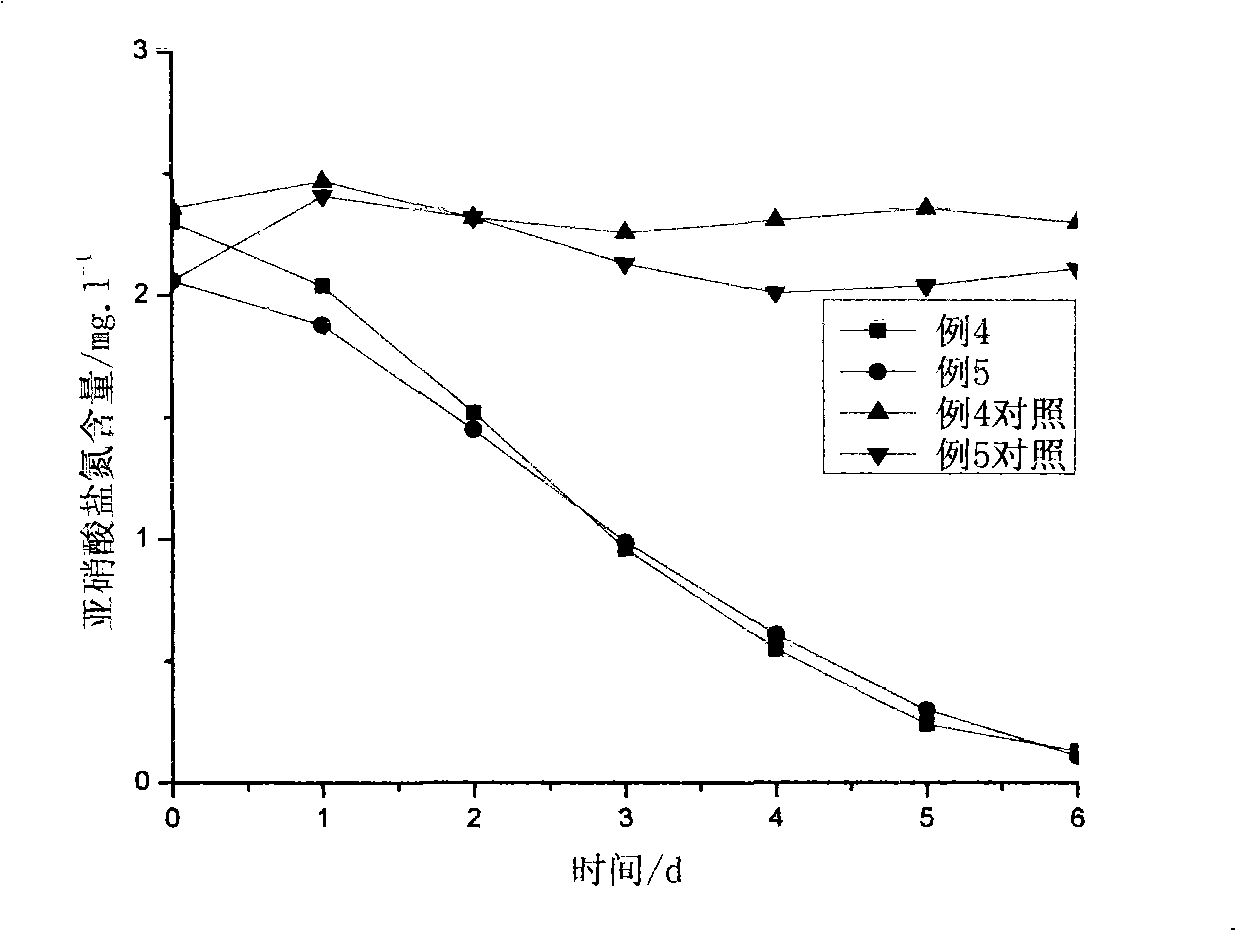

Embodiment 1

[0032] (1) Preparation of nitrifying bacteria concentrated solution: measure the optical density (OD 600 ) is 0.765, the bacterium solution is left standstill for 8h, the bacterium will be flocculated and deposited on the bottom of the container, remove the supernatant, collect the concentrated thalline at the bottom, measure the concentrated solution volume 10ml, the thalline concentration of the concentrated solution can be obtained by the following formula:

[0033] Bacteria concentration (g / L) = 1.271×OD 600 ×V 1 / V 2 =1.271×0.765×500 / 10=48.62

[0034] Then release the concentrated bacterial solution to 30g / L with physiological saline to obtain the concentrated solution of nitrifying bacteria for embedding.

[0035](2) Preparation of nitrifying bacteria immobilized particles: 200ml weight percent concentration is 8% polyvinyl alcohol (PVA), 3% sodium alginate (SA) and 2% water mixture heating of silicon dioxide to fully dissolve, After mixing, make embedding solution, ...

Embodiment 2

[0040] (1) Preparation of nitrifying bacteria concentrated solution: measure the optical density (OD 600 ) is 0.780, the bacterium liquid is left standstill for 14h, the bacterium will be flocculated and deposited on the bottom of the container, remove the supernatant, collect the concentrated thalline at the bottom, measure the concentrated liquid volume 15ml, the thalline concentration of the concentrated liquid can be obtained by the following formula

[0041] Bacteria concentration (g / L) = 1.271×OD 600 ×V 1 / V 2 =1.271×0.780×500 / 15=33.05

[0042] Then release the concentrated bacterial solution to 20g / L with physiological saline to obtain the concentrated solution of nitrifying bacteria for embedding;

[0043] (2) Preparation of nitrifying bacteria immobilized granules: fully dissolve by heating the water mixture of 10% polyvinyl alcohol (PVA), 1% sodium alginate (SA) and 2% silicon dioxide with 200ml weight percent concentration 1. Mix well to make embedding solution....

Embodiment 3

[0048] (1) Preparation of nitrifying bacteria concentrated solution: measure the optical density (OD 600 ) is 0.803, the bacterium solution is left standstill for 11h, the bacterium will be flocculated and deposited on the bottom of the container, remove the supernatant, collect the concentrated thalline at the bottom, measure the concentrated solution volume 14ml, the thalline concentration of the concentrated solution can be obtained by the following formula

[0049] Bacteria concentration (g / L) = 1.271×OD 600 ×V 1 / V 2 =1.271×0.803×500 / 14=36.45

[0050] Then release the concentrated bacterial solution to 25g / L with physiological saline to obtain the concentrated solution of nitrifying bacteria for embedding;

[0051] (2) Preparation of nitrifying bacteria immobilized granules: fully dissolve by heating the water mixture of 9% polyvinyl alcohol (PVA), 2% sodium alginate (SA) and 1% silicon dioxide with 200ml concentration by weight 1. Mix well to make embedding solution....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com