Anticoagulant composite hollow fiber membrane and preparation method thereof

An anticoagulant and fiber membrane technology, which is applied in the field of anticoagulant composite hollow fiber membrane and its preparation, can solve the problems of low blood coagulation performance, high preparation cost, easy elution, etc., and achieves improved biocompatibility and simple preparation method , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

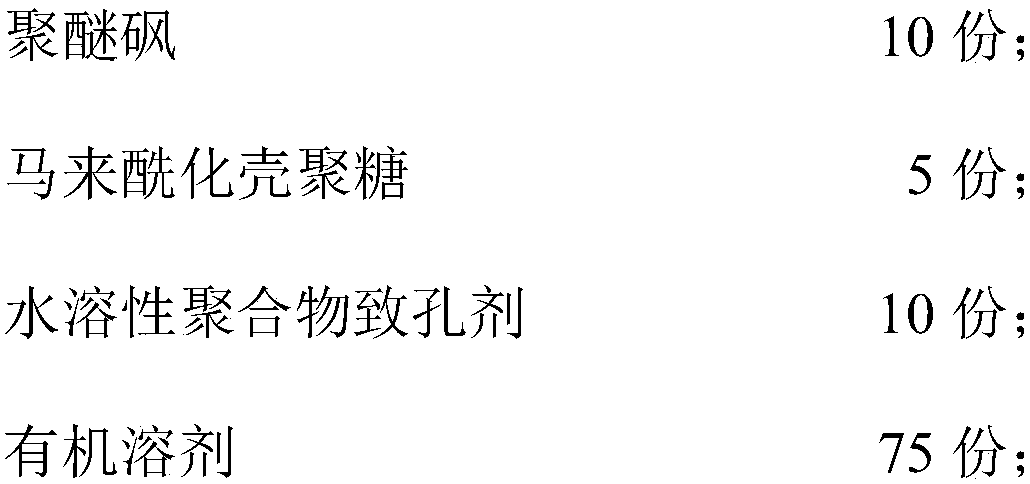

[0032] The invention provides an anticoagulant composite hollow fiber membrane, which comprises the following raw materials in parts by weight:

[0033]

[0034] Wherein, the viscosity-average molecular weight of the above-mentioned polyethersulfone is 50000; the above-mentioned maleylated chitosan is N-maleoylated chitosan, and the viscosity-average molecular weight is 5000; the above-mentioned water-soluble polymeric porogen is polyvinylpyrrolidone (PVP-K30); the above-mentioned organic solvent is dimethylacetamide.

[0035] The invention provides a preparation method for preparing an anticoagulant composite hollow fiber membrane by using the above-mentioned raw materials, comprising the following steps:

[0036] (1) Preparation of spinning dope

[0037] The polyethersulfone of 10 weight parts, the N-maleoylated chitosan of 5 weight parts, the polyvinylpyrrolidone (PVP-K30) of 10 weight parts are dissolved in the dimethylacetamide of 75 weight parts, heating to 70°C, st...

Embodiment 2

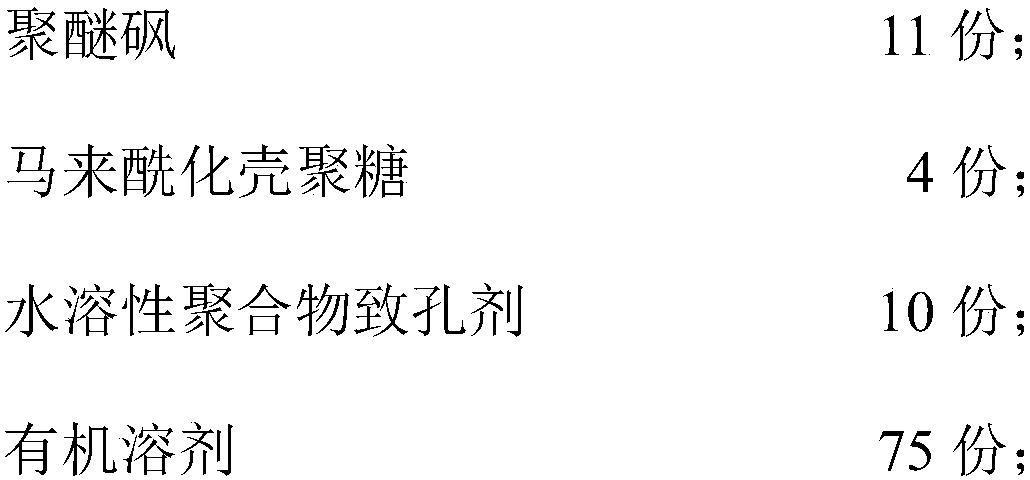

[0046] The invention provides an anticoagulant composite hollow fiber membrane, which comprises the following raw materials in parts by weight:

[0047]

[0048] Wherein, the viscosity-average molecular weight of the above-mentioned polyethersulfone is 60000; the above-mentioned maleylated chitosan is N-maleoylated chitosan, and the viscosity-average molecular weight is 100000; the above-mentioned water-soluble polymeric porogen is polyethylene glycol , the molecular weight is 10000; the above organic solvent is dimethyl sulfoxide.

[0049] The invention provides a preparation method for preparing an anticoagulant composite hollow fiber membrane by using the above-mentioned raw materials, comprising the following steps:

[0050] (1) Preparation of spinning dope

[0051] Dissolve 11 parts by weight of polyethersulfone, 4 parts by weight of N-maleoylated chitosan, and 10 parts by weight of polyethylene glycol in 75 parts by weight of dimethyl sulfoxide, heat to 75 ° C, and s...

Embodiment 3

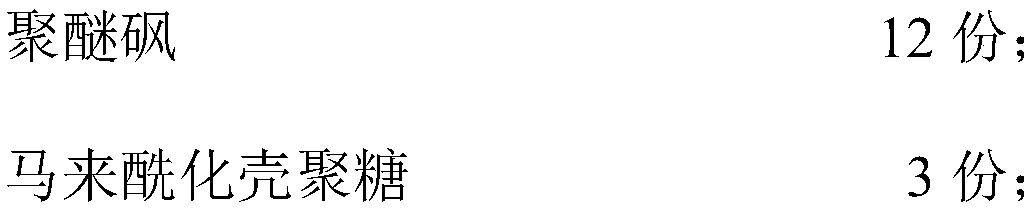

[0060] The invention provides an anticoagulant composite hollow fiber membrane, which comprises the following raw materials in parts by weight:

[0061]

[0062]

[0063] Wherein, the viscosity-average molecular weight of the above-mentioned polyethersulfone is 60000; the above-mentioned maleylated chitosan is N-maleoylated chitosan, and the viscosity-average molecular weight is 15000; the above-mentioned water-soluble polymeric porogen is polyvinylpyrrolidone (PVP-K90); the above-mentioned organic solvent is dimethylformamide.

[0064] The invention provides a preparation method for preparing an anticoagulant composite hollow fiber membrane by using the above-mentioned raw materials, comprising the following steps:

[0065] (1) Preparation of spinning dope

[0066] The polyethersulfone of 12 weight parts, the N-maleoylated chitosan of 3 weight parts, the polyvinylpyrrolidone (PVP-K90) of 5 weight parts are dissolved in the dimethylformamide of 77 weight parts, heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com