Chemical wastewater treatment agent and preparation method thereof

A technology for chemical wastewater and treatment agent, which is used in water treatment parameter control, water/sewage treatment, chemical instruments and methods, etc., to achieve the effect of improving coagulation and decolorization effect, removing odor, and saving water treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

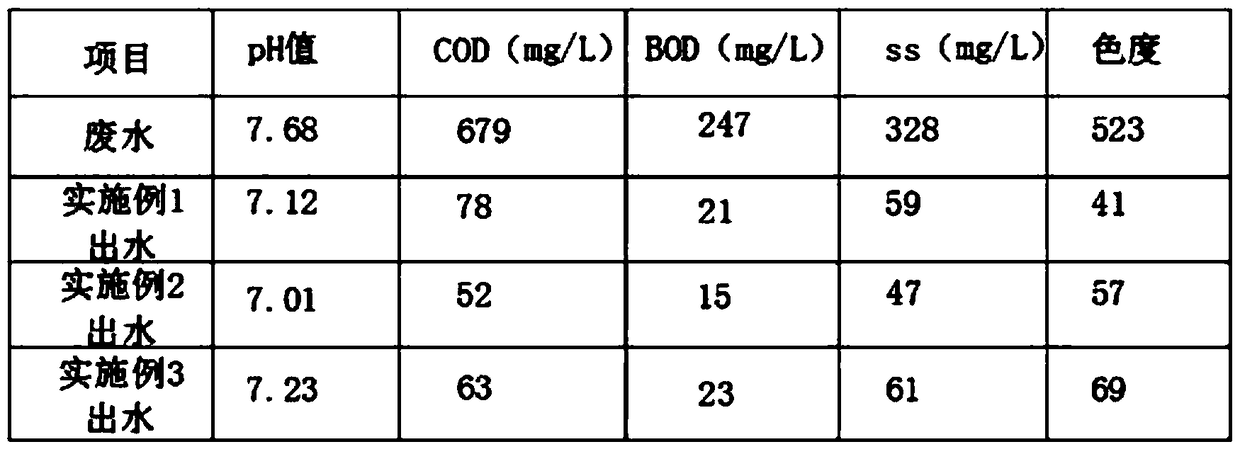

Examples

Embodiment 1

[0028] A chemical wastewater treatment agent, the treatment agent is composed of the following raw materials in terms of parts by mass: 25 parts of inorganic-organic flocculants, 15 parts of adsorbents, 10 parts of solidified red bayberry tannin, 10 parts of sulfuric acid modified pine leaves, compound biochemical 10 parts of adsorbent, 8 parts of activated bentonite, 5 parts of fly ash, 5 parts of peat, 8 parts of modified zeolite, 3 parts of diatomite and 3 parts of modified kaolin.

[0029] Inorganic-organic flocculant is compounded by organic flocculant and inorganic flocculant according to 4:1. The organic flocculant is carboxymethyl chitosan prepared by the reaction of chitosan and chloroacetic acid. The inorganic flocculant is made of sulfuric acid heptahydrate Polymerized ferric phosphate sulfate made from ferrous iron, carboxymethyl chitosan and polymerized ferric phosphate sulfate are mixed at a ratio of 4:1 to prepare an inorganic-organic flocculant.

[0030] The ad...

Embodiment 2

[0043] A chemical wastewater treatment agent, the treatment agent consists of the following raw materials in terms of parts by mass: 30 parts of inorganic-organic flocculant, 30 parts of adsorbent, 15 parts of solidified bayberry tannin, 15 parts of sulfuric acid modified pine leaves, compound biochemical 12 parts of adsorbent, 10 parts of activated bentonite, 6 parts of fly ash, 6 parts of peat, 9 parts of modified zeolite, 5 parts of diatomite and 5 parts of modified kaolin.

[0044]Inorganic-organic flocculant is compounded by organic flocculant and inorganic flocculant according to 4:1. The organic flocculant is carboxymethyl chitosan prepared by the reaction of chitosan and chloroacetic acid. The inorganic flocculant is made of sulfuric acid heptahydrate Polymerized ferric phosphate sulfate made from ferrous iron, carboxymethyl chitosan and polymerized ferric phosphate sulfate are mixed at a ratio of 4:1 to prepare an inorganic-organic flocculant.

[0045] The adsorbent i...

Embodiment 3

[0058] A chemical wastewater treatment agent, the treatment agent is composed of the following raw materials in terms of parts by mass: 38 parts of inorganic-organic flocculants, 27 parts of adsorbents, 18 parts of solidified red bayberry tannin, 18 parts of sulfuric acid modified pine leaves, compound biochemical 15 parts of adsorbent, 12 parts of activated bentonite, 8 parts of fly ash, 8 parts of peat, 10 parts of modified zeolite, 8 parts of diatomite and 8 parts of modified kaolin.

[0059] Inorganic-organic flocculant is compounded by organic flocculant and inorganic flocculant according to 4:1. The organic flocculant is carboxymethyl chitosan prepared by the reaction of chitosan and chloroacetic acid. The inorganic flocculant is made of sulfuric acid heptahydrate Polymerized ferric phosphate sulfate made from ferrous iron, carboxymethyl chitosan and polymerized ferric phosphate sulfate are mixed at a ratio of 4:1 to prepare an inorganic-organic flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com