Polyamine formaldehyde-free fixing agent as well as preparation and application method thereof

An aldehyde-free color-fixing agent and amine technology, applied in the field of additives, can solve the problems of increasing product processing procedures, reducing production efficiency, increasing product costs, etc., and achieving the effects of improving color fastness, improving quality, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

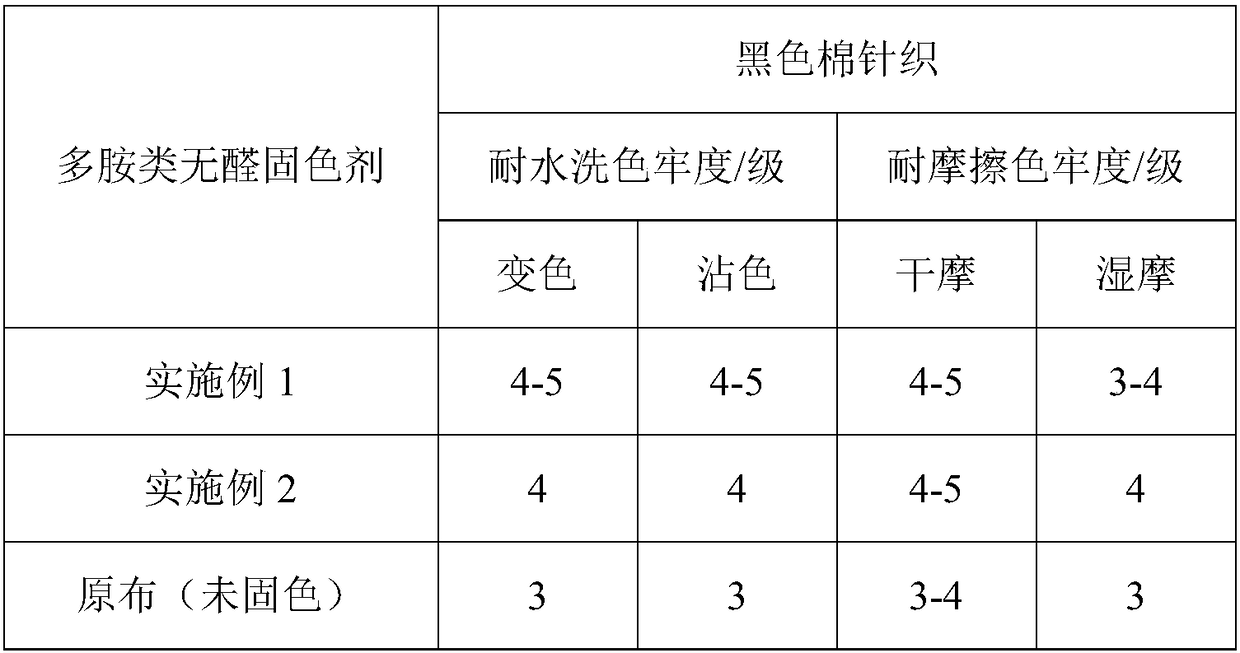

Examples

Embodiment 1

[0031] Provide the following raw materials by weight: 10 parts of diethylenetriamine, 8 parts of N-aminoethylpiperazine, 12 parts of ammonium chloride, 16 parts of dicyandiamide, 5 parts of formic acid, 14 parts of diethylene glycol, epichlorohydrin 8 parts, 15 parts of 2,3-epoxypropyltrimethylammonium chloride, 6 parts of polyvinyl alcohol PVA and 45 parts of deionized water.

[0032] In the present embodiment, the preparation process it involves includes the following steps:

[0033] Add the diethylenetriamine and N-aminoethylpiperazine in sequence to a reaction vessel, start stirring, and heat to 90°C;

[0034] Slowly add the ammonium chloride to carry out cationic quaternization reaction, and react at 90°C for 2 hours;

[0035] Add the diethylene glycol, raise the temperature to 120°C, slowly add the dicyandiamide, after the addition, raise the temperature to 160°C, and conduct polycondensation for 2.5 hours;

[0036] Cool down to 80°C, quickly add the deionized water, a...

Embodiment 2

[0040] Provide the following raw materials by weight: 14 parts of tetraethylenepentamine, 10 parts of N-aminoethylpiperazine, 15 parts of ammonium chloride, 18 parts of dicyandiamide, 4 parts of hydrochloric acid, 13 parts of ethylene glycol, epichlorohydrin 10 parts, 15 parts of 2,3-epoxypropyltrimethylammonium chloride, 8 parts of polyvinyl alcohol PVA and 50 parts of deionized water.

[0041] In the present embodiment, the preparation process it involves includes the following steps:

[0042] Add the tetraethylenepentamine and N-aminoethylpiperazine sequentially into a reaction vessel, start stirring, and heat to 90°C;

[0043] Slowly add the ammonium chloride to carry out cationic quaternization reaction, and react at 90°C for 2 hours;

[0044] Add the ethylene glycol, raise the temperature to 120°C, slowly add dicyandiamide, after the addition, raise the temperature to 160°C, and perform polycondensation for 3 hours;

[0045] Cool down to 80°C, quickly add the deionized...

Embodiment 3

[0052] Provide the following raw materials by weight: 14 parts of triethylenetetramine, 10 parts of N-aminoethylpiperazine, 15 parts of ammonium chloride, 18 parts of dicyandiamide, 4 parts of glacial acetic acid, 13 parts of glycerol, epoxy chloride 10 parts of propane, 15 parts of 2,3-epoxypropyltrimethylammonium chloride, 8 parts of polyvinyl alcohol PVA and 50 parts of deionized water.

[0053] In the present embodiment, the preparation process it involves includes the following steps:

[0054] Add the triethylenetetramine and N-aminoethylpiperazine sequentially into a reaction vessel, start stirring, and heat to 90°C;

[0055] Slowly add the ammonium chloride to carry out cationic quaternization reaction and react at 90°C for 1.5 hours;

[0056] Add the glycerol, raise the temperature to 120°C, slowly add the dicyandiamide, after the addition, raise the temperature to 160°C, and conduct the polycondensation reaction for 2.5 hours;

[0057] Cool down to 80°C, quickly add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com