Environment-friendly hydrophilic color fixing agent for cotton and preparation method thereof

A color-fixing agent and an environment-friendly technology, which is applied in the direction of dyeing, plant fiber, fiber treatment, etc., can solve the problem that the color fastness of the fabric cannot be guaranteed and the hydrophilicity, hydrophilicity and handfeel have not been improved, and the color-fixing agent Problems such as good and bad are uneven, to achieve the effect of improving color fastness, improving color fastness, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

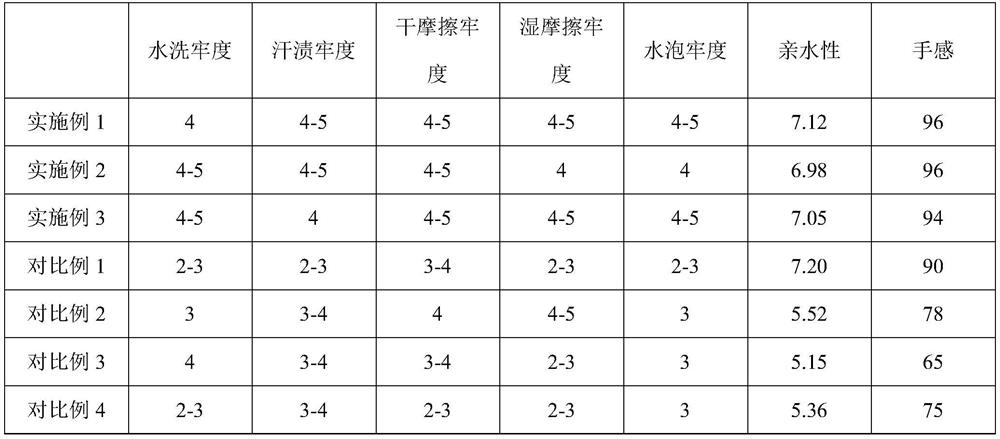

Examples

Embodiment 1

[0040] The preparation method of described environment-friendly type cotton with hydrophilic color-fixing agent:

[0041] (1) Add triethanolamine and epichlorohydrin sequentially to the reaction vessel, heat up to 85°C and react for 2 hours to obtain a hydroxyl-terminated quaternary ammonium salt chain extender, wash the resulting product with acetone several times, and remove it by distillation under reduced pressure Residual solvent, vacuum drying, the mol ratio of triethanolamine and epichlorohydrin is 0.7:1;

[0042] (2) Put polyoxypropylene diol into the reactor, distill under reduced pressure at 100°C for 2 hours, add acetone after adjusting the temperature to 50°C, seal it for later use, and add 1,6-hexamethylene diisocyanate into the dry reactor , under the protection of nitrogen, drop the above polyoxypropylene diol, and add dibutyltin dilaurate, control the temperature at 60 ° C, and keep it warm for 1 hour to prepare a polyurethane prepolymer; polyoxypropylene diol,...

Embodiment 2

[0047] The preparation method of described environment-friendly type cotton with hydrophilic color-fixing agent:

[0048] (1) Add diisopropanolamine and epichlorohydrin successively to the reaction vessel, heat up to 95° C. and react for 1 hour to obtain a hydroxyl-terminated quaternary ammonium salt chain extender. The resulting product is washed several times with acetone, and the Pressure distillation removes residual solvent, vacuum drying, the mol ratio of triethanolamine and epichlorohydrin is 1:1;

[0049] (2) Put polyoxypropylene diol into the reactor, distill under reduced pressure at 110°C for 2 hours, add acetone after adjusting the temperature to 50°C, seal it for later use, and add 1,6-hexamethylene diisocyanate into the dry reactor , under the protection of nitrogen, drop the above polyoxypropylene diol, and add ditin octoate, control the temperature at 58 ° C, keep warm for 1 hour, and obtain a polyurethane prepolymer; polyoxypropylene diol, 1,6-hexanediol The ...

Embodiment 3

[0054] The preparation method of described environment-friendly type cotton with hydrophilic color-fixing agent:

[0055] (1) Add diisopropanolamine and epichlorohydrin successively to the reaction vessel, heat up to 90° C. and react for 1 hour to obtain a hydroxyl-terminated quaternary ammonium salt chain extender. The resulting product is washed several times with acetone, and the Pressure distillation removes residual solvent, vacuum drying, the mol ratio of triethanolamine and epichlorohydrin is 0.9:1;

[0056] (2) Put polyoxypropylene diol into the reactor, distill under reduced pressure at 105°C for 2 hours, adjust the temperature to 50°C, add acetone, seal it for later use, and add 1,6-hexamethylene diisocyanate into the dry reactor , under the protection of nitrogen, drop the above polyoxypropylene diol, and add zinc naphthenate, control the temperature at 62 ° C, keep the reaction for 1.5 hours, and obtain a polyurethane prepolymer; polyoxypropylene diol, 1,6-hexane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com