Flocculant and preparation method therefor

A flocculant and initiator technology, applied in the field of flocculants and their preparation, can solve problems such as the increase of free formaldehyde, and achieve the effects of reduced formaldehyde emission, good effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

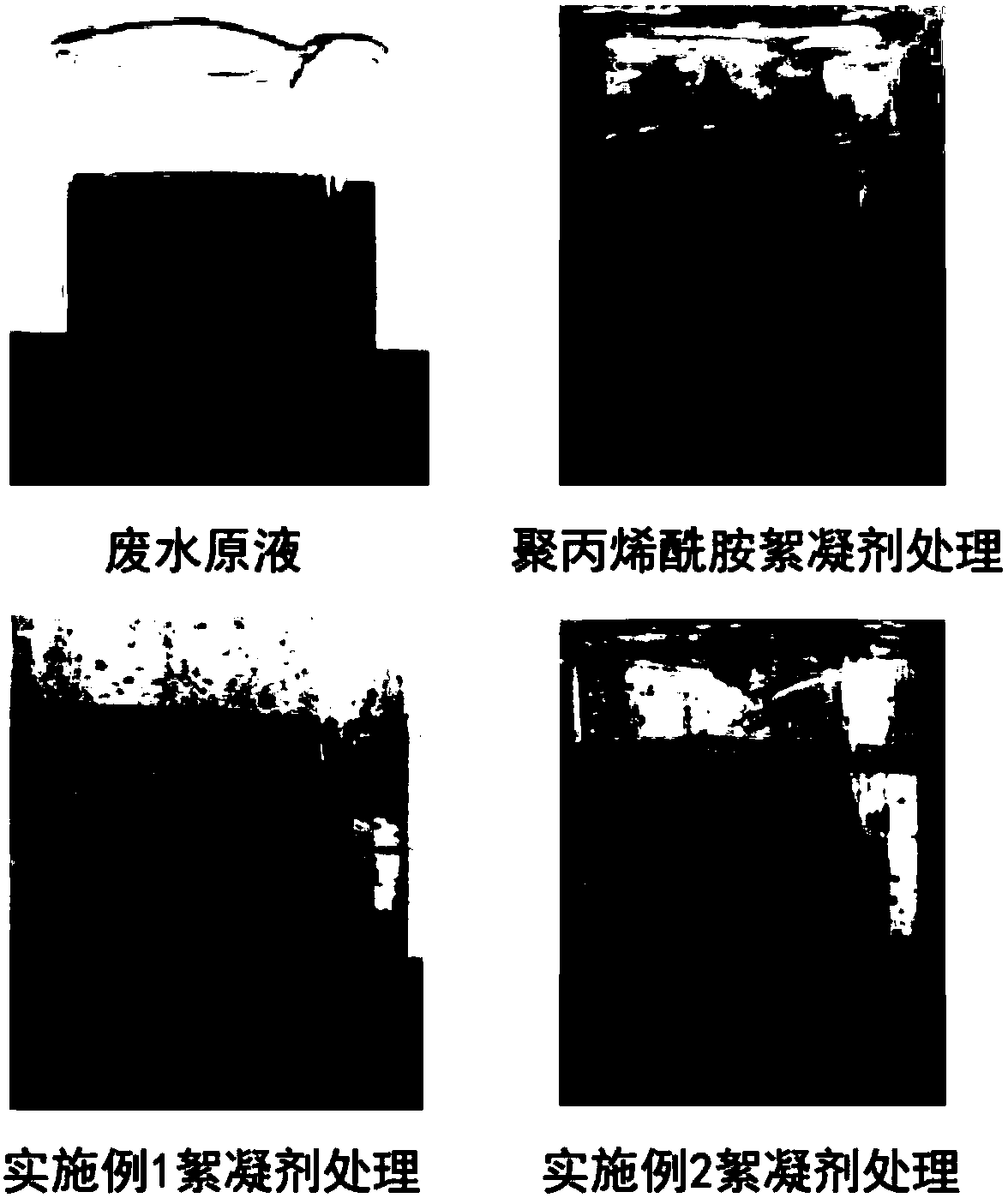

Image

Examples

Embodiment 1

[0030] The present embodiment provides a preparation method of a flocculant, which comprises the following steps:

[0031] S1) add acrylamide, quaternary ammonium salt monomer, amine, aldehyde, complexing agent, cosolvent and water to the reactor, and stir;

[0032] S2) adjust the temperature in the reactor to 5°C, and feed nitrogen into the reactor; after the nitrogen is passed in for at least 20 minutes, add initiator A to the reactor; after 20 minutes of reaction, continue to add initiator B to the reactor; After adding B, stop feeding nitrogen and continue to react for 5h;

[0033] S3) raising the temperature in the reactor to 35°C, and adding the catalyst dropwise to the reactor after 5h; after adding the catalyst, raising the temperature in the reactor to 60°C and reacting for 5h;

[0034] S4) adding etherifying agent to the reactor, after reacting for 3h, the flocculant is obtained;

[0035] The mass concentration of acrylamide in the mixture is 15.75%, the mass conce...

Embodiment 2

[0040] The present embodiment provides a preparation method of a flocculant, which comprises the following steps:

[0041] S1) add acrylamide, quaternary ammonium salt monomer, amine, aldehyde, complexing agent, cosolvent and water to the reactor, and stir;

[0042] S2) adjust the temperature in the reactor to 20°C, and feed nitrogen into the reactor; after the nitrogen is fed for at least 20 minutes, add initiator A to the reactor; after 13 minutes of reaction, continue to add initiator B to the reactor; After adding B, stop feeding nitrogen and continue to react for 3h;

[0043] S3) raising the temperature in the reactor to 40°C, and adding the catalyst dropwise to the reactor after 3.5 hours; after adding the catalyst, raising the temperature in the reactor to 80°C, and reacting for 4 hours;

[0044] S4) adding an etherifying agent to the reactor, and reacting for 2h to obtain a flocculant;

[0045] The mass concentration of acrylamide in the mixture is 17.5%, the mass conc...

Embodiment 3

[0050] The present embodiment provides a preparation method of a flocculant, which comprises the following steps:

[0051] S1) add acrylamide, quaternary ammonium salt monomer, amine, aldehyde, complexing agent, cosolvent and water to the reactor, and stir;

[0052] S2) adjust the temperature in the reactor to 25°C, and feed nitrogen into the reactor; after the nitrogen is passed in for at least 20 minutes, add initiator A to the reactor; after 10 minutes of reaction, continue to add initiator B to the reactor; After adding B, stop feeding nitrogen and continue to react for 2h;

[0053] S3) raising the temperature in the reactor to 50°C, and adding the catalyst dropwise to the reactor after 2 hours; after adding the catalyst, raising the temperature in the reactor to 90°C, and reacting for 2 hours;

[0054] S4) adding an etherifying agent to the reactor, and reacting for 1 h to obtain a flocculant;

[0055] The mass concentration of acrylamide in the mixture is 19.25%, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com