Method for treating chrome tanning wastewater

A treatment method and wastewater technology, which is applied in animal processing wastewater treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve steric hindrance or space mismatch, poor removal effect of heavy metals, small molecules Precipitant residues and other problems, to achieve a high degree of reaction completion, excellent treatment effect, conducive to the formation and growth of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A flocculant used for the treatment of chrome tanning wastewater, the flocculant includes a chitosan-derived adsorption material; the chitosan-derived adsorbent is prepared by the following steps: dispersing triethylenetetramine and chitosan in an acetic acid solution , and then add a cross-linking agent to react, then wash and dry to obtain the product; the above-mentioned cross-linking agent contains glutaraldehyde, triethanolamine and 3-mercaptopropionic acid. Chitosan, a natural high molecular polymer, is an amino polysaccharide with cationic polyelectrolyte properties, and has good biocompatibility. It can undergo ion exchange with anionic compounds under acidic conditions. Or organic pollutants have numerous adsorption sites, so chitosan-derived materials have broad application prospects in wastewater treatment.

[0035] The chitosan-derived adsorption material is prepared through the following specific steps: take triethylenetetramine and chitosan in a ratio of 1...

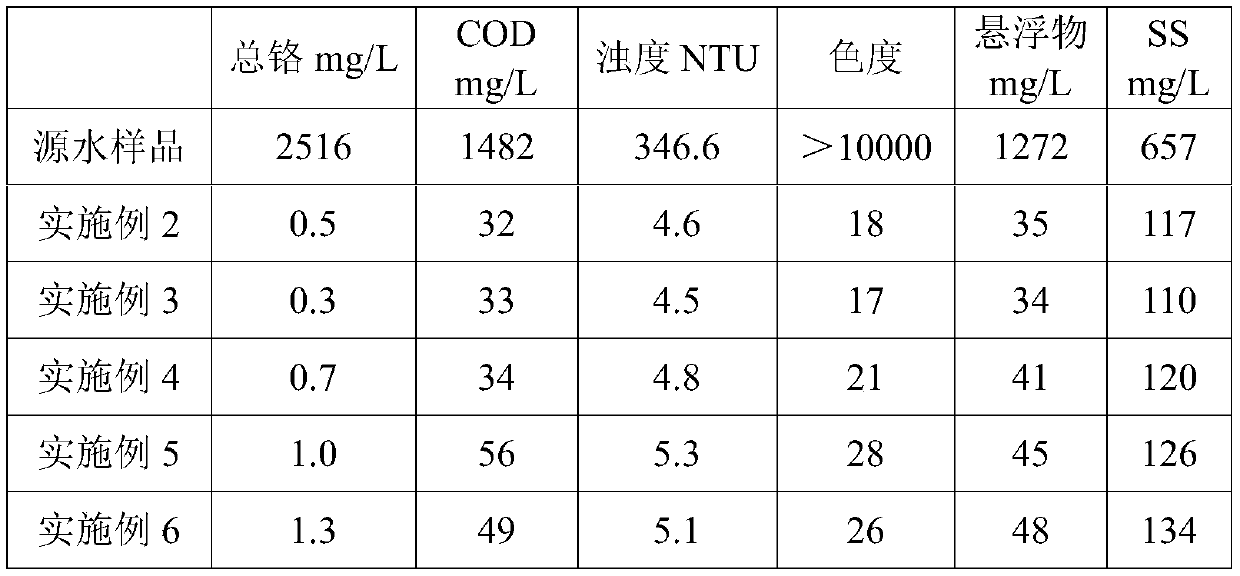

Embodiment 2

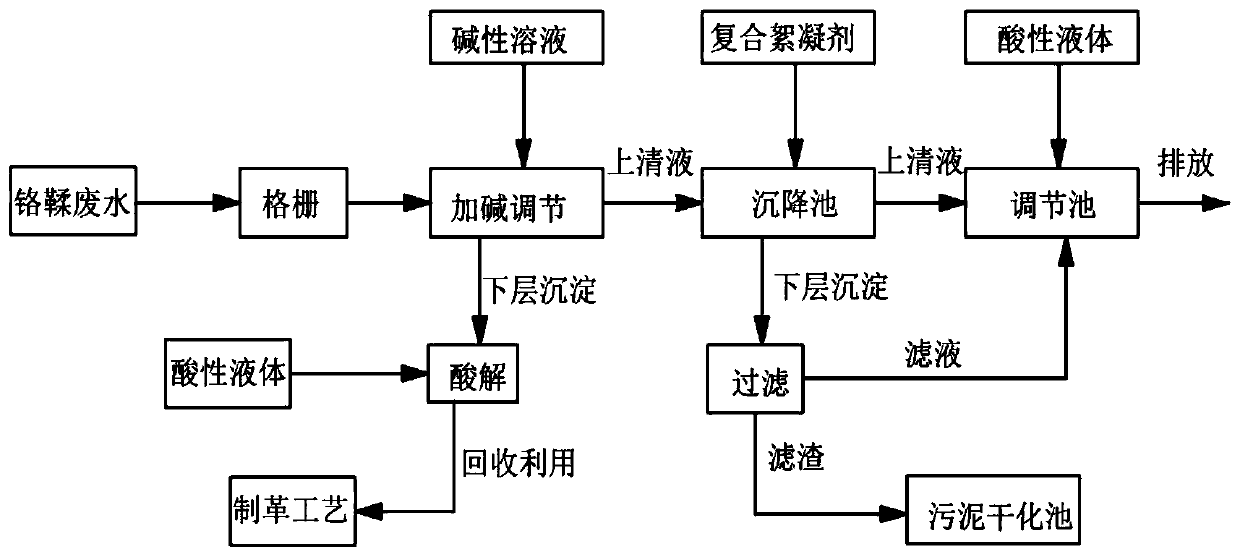

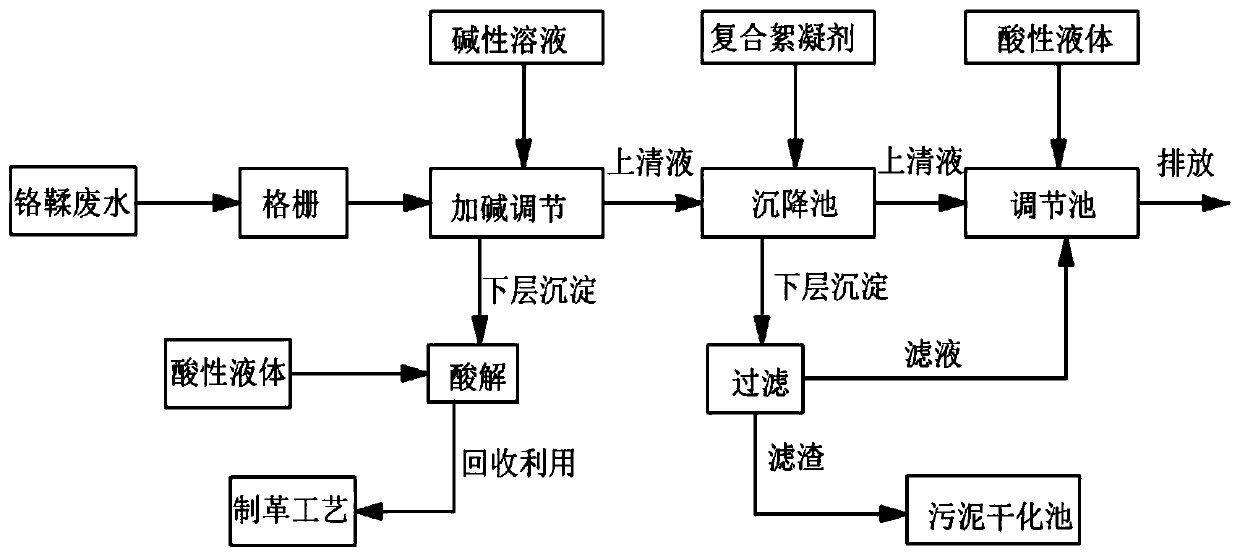

[0050] The processing method of chrome tanning waste water, it specifically comprises the following steps:

[0051] 1) Grille removal of impurities: the chrome tanning wastewater is passed through the grid to remove impurities, the mesh screen used is 40 mesh, and the hydraulic retention time is 3h;

[0052] 2) Alkali adjustment: add 4.2kg / t of sodium hydroxide solution to the waste water after impurity removal for precipitation treatment, and adjust the pH value of the waste water to 8, and then recover the resulting precipitate, which can be recovered by acid hydrolysis For tanning process;

[0053] 3) Wastewater settlement: add 33L / m to the waste water 2 After flocculant, react at a stirring speed of 80r / min for 30min, then let it stand for 1h, then send the supernatant to the adjustment tank, after the lower layer is precipitated and filtered, the filtrate is sent to the adjustment tank, and the filter residue is sent to the sludge drying tank. The weight ratio of the am...

Embodiment 3

[0061] In this example, the preparation of the amphoteric polymer chelating flocculant PDDMAMDTC used in the flocculant is optimized, and the specific optimization measures are as follows:

[0062] Step 1, take dimethyl diallyl ammonium chloride and acrylamide monomers at a molar ratio of 0.5:1, add deionized water to dissolve and prepare a mixed solution with a mass concentration of 23.5%, and then inject nitrogen to drive oxygen for 30 minutes, Then add 0.16wt% ammonium persulfate, 0.04% sodium oxalate and 0.02% dimethyl sulfoxide to the mixed solution, react at a temperature of 65°C for 1.5h, and rinse with methanol to obtain the copolymer P(DMDAAC -AM), as the cationic degree of the copolymerized product increases, the steric effect and charge repulsion effect formed after the addition of the cation is also enhanced, which will reduce the reactivity of the monomer in the system, and also inhibit the continuation of the intrinsic viscosity of the polymerized product. growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com