High-cation-degree asphalt emulsifier and application thereof

A technology of asphalt emulsifier and cationic degree, applied in organic chemistry, building components, building insulation materials, etc., can solve the problem of inability to prepare emulsified asphalt with high solid content, and achieve large steric hindrance, high cationic degree, and strong permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of high cationic asphalt emulsifier

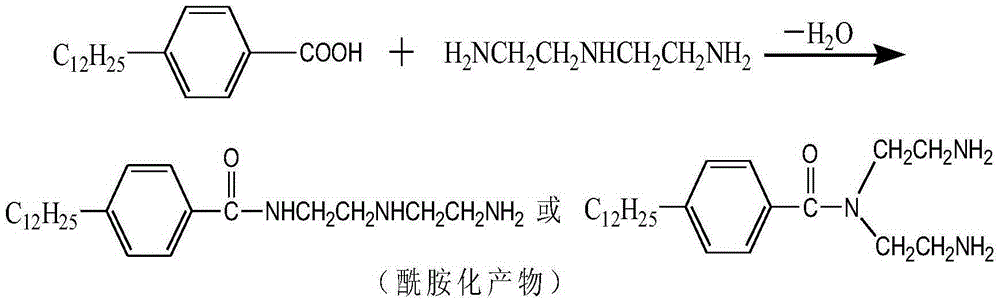

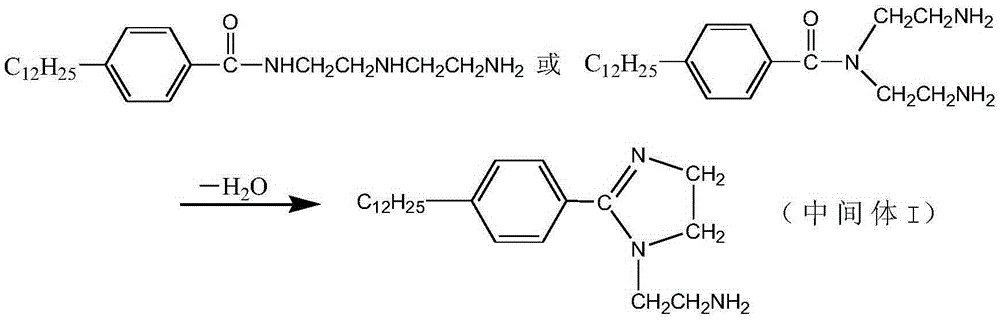

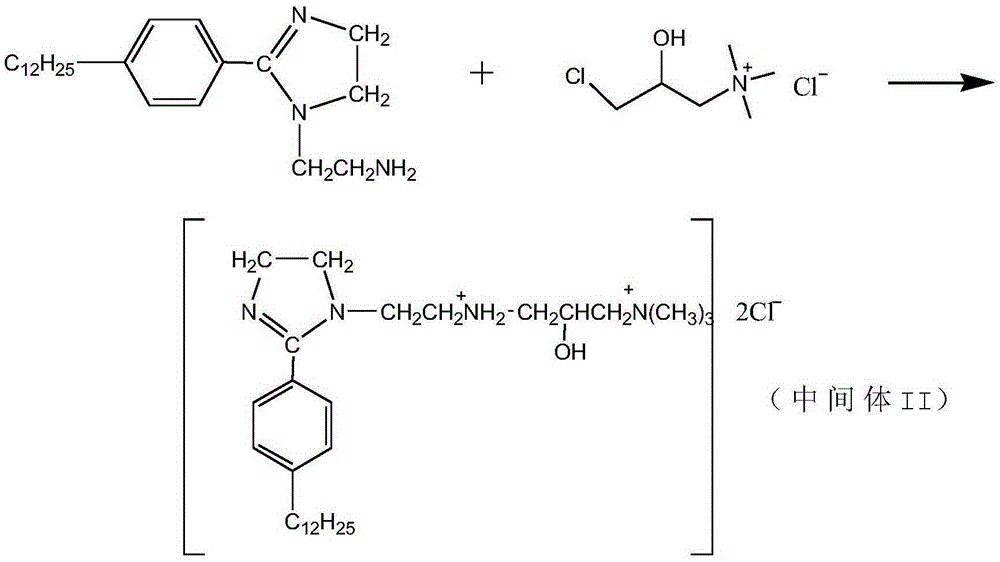

[0035] 1) Add 290.4g (1.0mol) of dodecyl-terebenzoic acid into the reaction vessel, stir and dehydrate at 110°C and 5mmHg for 1 hour, then add 103.2g (1.0mol) of diethylenetriamine into the reaction vessel, Heat up to 150°C and stir for 6 hours, continue to heat up to 200°C for 5 hours, then cool down to 50°C, add 236g of absolute ethanol and stir to dissolve for 1h to obtain intermediate I solution; 2) Add 470g of 40% (1.0mol) 3 -Chloro-2-hydroxypropyltrimethylammonium chloride aqueous solution was added dropwise to the ethanol solution of intermediate I in 1h, and after the addition was completed, the reaction was continued at 70°C for 4h to obtain intermediate II; 3) intermediate II was cooled After reaching 60° C., add 243 g of 30% (2.0 mol) industrial hydrochloric acid within 30 minutes, and continue stirring for 1 hour to obtain the final product, a highly cationic asphalt emulsifier. The solid content of the ...

Embodiment 2

[0041] (1) Preparation of high cationic asphalt emulsifier

[0042]1) Add 290.4g (1.0mol) of dodecyl-terebenzoic acid into the reaction vessel, stir and dehydrate at 110°C and 5mmHg for 1 hour, then add 113.5g (1.1mol) of diethylenetriamine into the reaction vessel, Raise the temperature to 155°C and stir the reaction for 5h, continue to heat up to 210°C for 3h, then cool down to 60°C, add 283g of absolute ethanol and stir to dissolve for 1h to obtain the intermediate I solution; -Chloro-2-hydroxypropyltrimethylammonium chloride aqueous solution was added dropwise to the ethanol solution of intermediate I in 1h, after the dropwise addition was completed, the temperature was raised to 80°C and reacted for 3h to obtain intermediate II; 3) Intermediate II After cooling to 60° C., add 401.5 g of 30% (3.3 mol) industrial hydrochloric acid within 30 minutes, and continue stirring for 30 minutes to obtain the final product of high cationic asphalt emulsifier. The solid content of th...

Embodiment 3

[0048] (1) Preparation of high cationic asphalt emulsifier

[0049] 1) Add 290.4g (1.0mol) of dodecyl-terebenzoic acid into the reaction vessel, stir and dehydrate at 110°C and 5mmHg for 1 hour, then add 123.8g (1.2mol) of diethylenetriamine into the reaction vessel, Heat up to 160°C and stir for 3 hours, continue to heat up to 220°C for 2 hours, then cool down to 70°C, add 331.4g of absolute ethanol and stir to dissolve for 1h to obtain Intermediate I solution; 2) Add 564g of 50% (1.5mol) 3-Chloro-2-hydroxypropyltrimethylammonium chloride aqueous solution was added dropwise to the ethanol solution of intermediate I in 1 hour, and after the dropwise addition was completed, the temperature was raised to 90°C and reacted for 2.5 hours to obtain intermediate II; 3) intermediate After the body II was cooled to 70°C, 584g of 30% (4.8mol) industrial hydrochloric acid was added within 30 minutes, and the stirring was continued for 1 hour to obtain the final product of high cationic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com