Surface-sizing fixing agent for color ink-jet paper and preparation method and application thereof

A technology of surface sizing and color spray paper, applied in papermaking, textiles and papermaking, non-fiber pulp addition, etc., can solve the problems of low cationicity of styrene-acrylic emulsion, poor water resistance of color fixing agent, etc., and improve surface properties , solve the effect of poor hydrophobicity and increase cationic groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

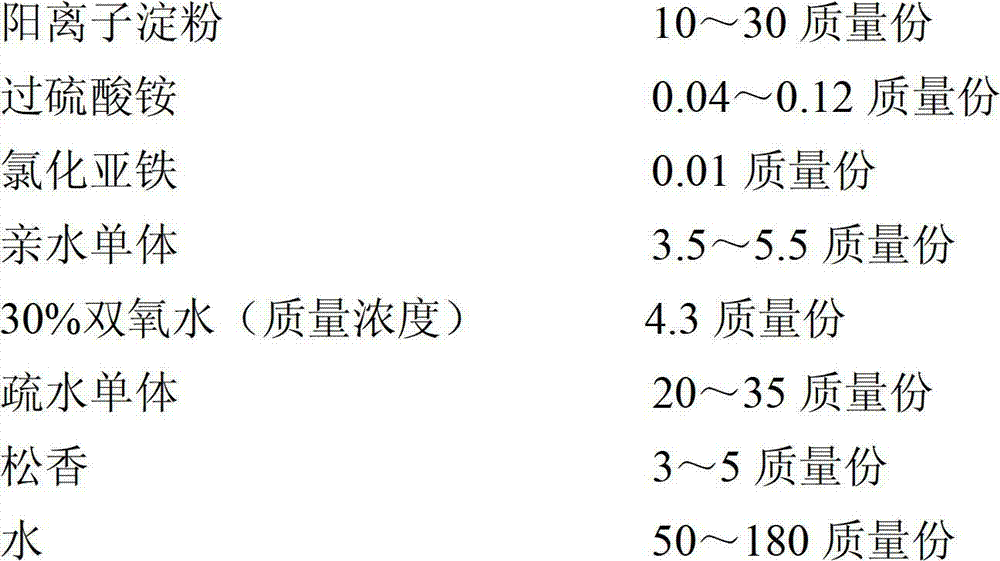

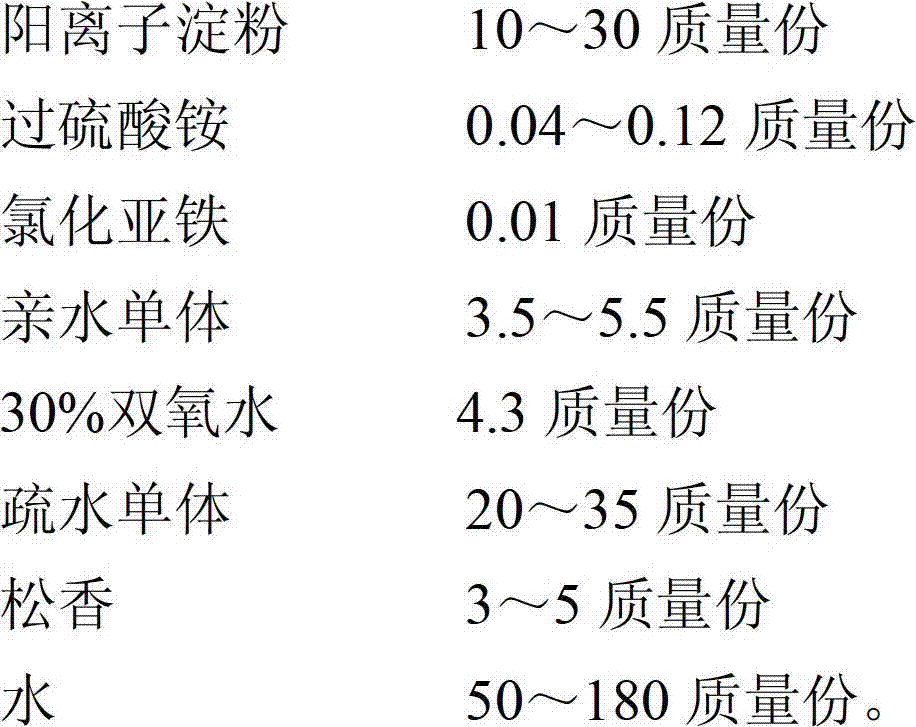

Method used

Image

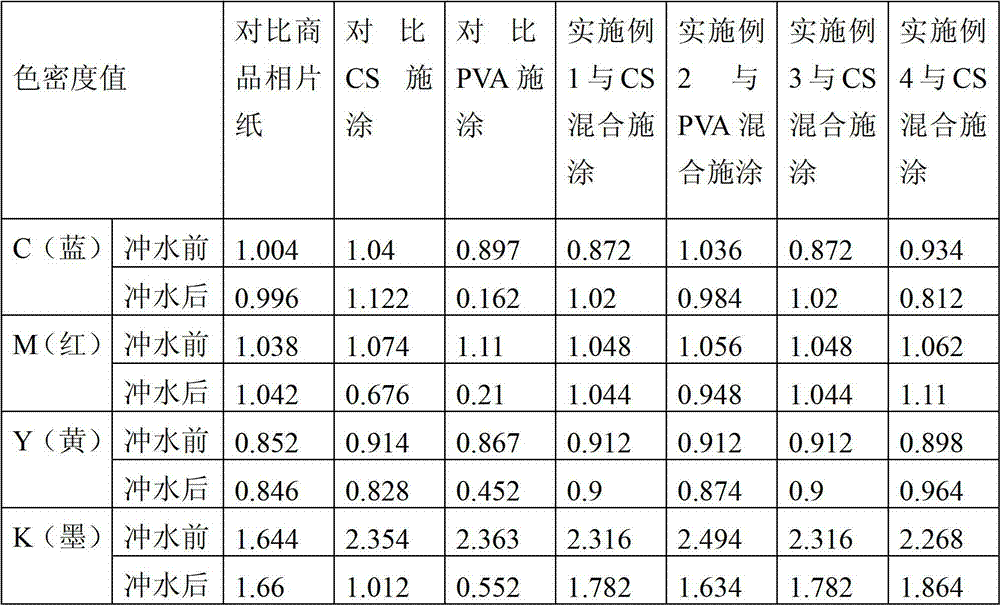

Examples

Embodiment 1

[0033] The preparation method of color jet paper surface sizing color-fixing agent of the present invention comprises the following steps:

[0034] (1) Weigh 10 parts by mass of cationic starch CS-8, 0.04 parts by mass of ammonium persulfate, and 24 parts by mass of water into a water bath in a four-neck flask, start the stirrer, and gelatinize at 85°C for 1 hour;

[0035] (2) Add ferrous chloride solution prepared by 0.01 parts by mass of ferrous chloride and 1 part by mass of water into a four-necked flask;

[0036] (3) Add a hydrophilic monomer solution prepared by 3.5 parts by mass of maleic anhydride and 8.5 parts by mass of water into a four-necked flask;

[0037] (4) Add dropwise a hydrogen peroxide dilution diluted with 0.8 parts by mass of 30% hydrogen peroxide and 1.5 parts by mass of water into a four-necked flask;

[0038] (5) After mixing 20 parts of a mixture of styrene and butyl acrylate (the mass ratio of styrene and butyl acrylate is 5:4) and 5 parts of rosin...

Embodiment 2

[0043] The preparation method of color jet paper surface sizing color-fixing agent of the present invention comprises the following steps:

[0044] (1) Weigh 20 parts by mass of cationic starch CS-8, 0.08 parts by mass of ammonium persulfate, and 48 parts by mass of water into a water bath in a four-neck flask, start the stirrer, and gelatinize at 85°C for 1 hour;

[0045] (2) Add ferrous chloride solution prepared by 0.01 parts by mass of ferrous chloride and 2 parts by mass of water into a four-necked flask;

[0046] (3) Add a hydrophilic monomer solution prepared by 3.5 parts by mass of maleic anhydride and 17 parts by mass of water into a four-necked flask;

[0047] (4) Add dropwise a hydrogen peroxide dilution diluted with 0.8 parts by mass of 30% hydrogen peroxide and 3 parts by mass of water into a four-necked flask;

[0048] (5) Mix 35 parts by mass of styrene and butyl acrylate (the mass ratio of styrene and butyl acrylate is 5:4) and 5 parts by mass of rosin in a be...

Embodiment 3

[0053] The preparation method of color jet paper surface sizing color-fixing agent of the present invention comprises the following steps:

[0054] (1) Weigh 30 parts by mass of cationic starch CS-8, 0.12 parts by mass of ammonium persulfate, and 86.4 parts by mass of water into a water bath in a four-neck flask, start the stirrer, and gelatinize at 85°C for 1 hour;

[0055] (2) Add ferrous chloride solution prepared by 0.01 parts by mass of ferrous chloride and 3.6 parts by mass of water into a four-necked flask;

[0056] (3) Add a hydrophilic monomer solution prepared by 5.5 parts by mass of hydrophilic monomer (maleic anhydride to acrylamide mass ratio 1:1) and 30.6 parts by mass of water into a four-necked flask;

[0057] (4) Add dropwise the hydrogen peroxide dilution diluted with 0.8 parts by mass of 30% hydrogen peroxide and 54 parts by mass of water into the four-necked flask;

[0058] (5) Mix 25 parts by mass of styrene and butyl acrylate (the mass ratio of styrene a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com