Method for preparing composite sludge dehydrant

A sludge dewatering agent and composite technology, which can be used in flocculation/sedimentation water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

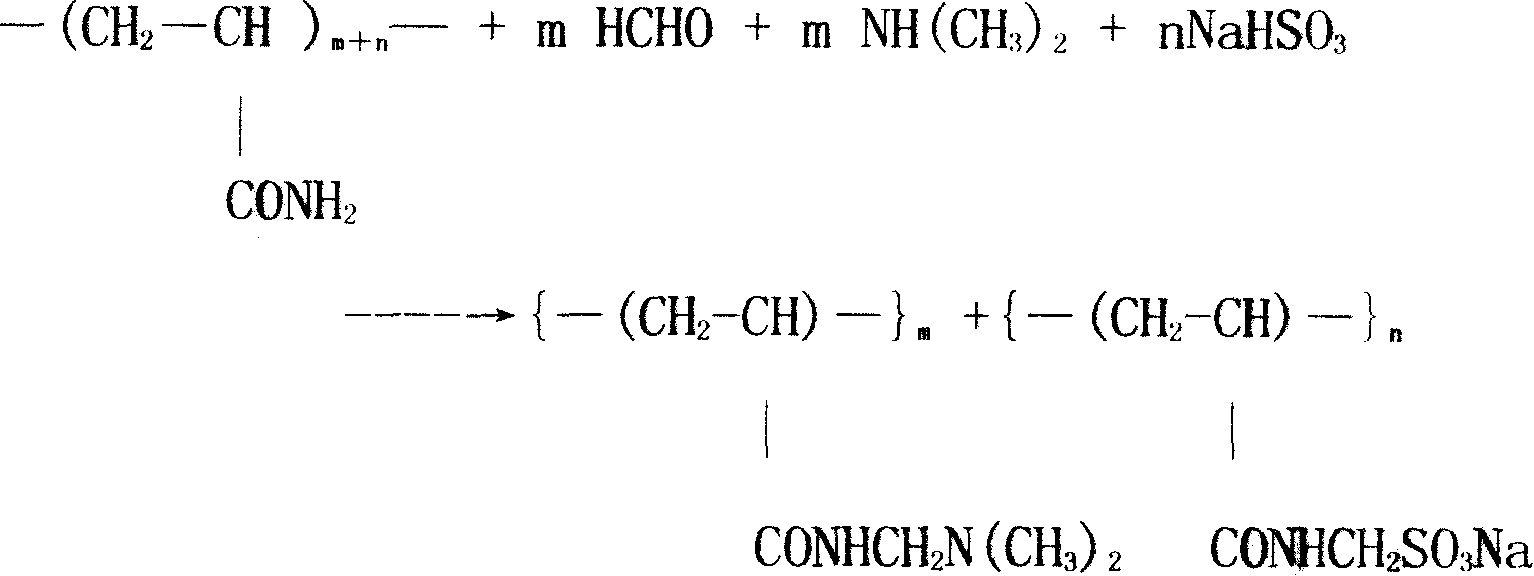

[0022] In the reactor, add 499kg of fresh water, start stirring, and add 1.1kg of nonionic polyacrylamide. After complete dissolution, add 0.1 kg of sodium hydroxide (chemically pure) to adjust the pH of the solution to 11-12. Then add 0.5g of disodium edetate (chemically pure), control the reaction temperature at 30°C, add 1200mL of formaldehyde (chemically pure), 1200mL of dimethylamine (chemically pure), and 0.73kg of sodium bisulfite into the reaction kettle , the reaction time is 4h. Finally, 1500 mL of hydrochloric acid (chemically pure) was added to stop the reaction to obtain amphoteric dehydrating agent-1.

Embodiment 2

[0024] In the reactor, add 498kg of fresh water, start stirring, and add 1.35kg of nonionic polyacrylamide. After completely dissolving, add 0.17kg of sodium hydroxide (chemically pure) to adjust the pH value of the solution to 9-10. Then add 0.5g of disodium edetate (chemically pure), control the reaction temperature at 50°C, add 2200mL of formaldehyde (chemically pure), 1800mL of dimethylamine (chemically pure), and 0.41kg of sodium bisulfite into the reaction kettle , the reaction time is 3h. Finally, 2500 mL of hydrochloric acid (chemically pure) was added to stop the reaction to obtain the amphoteric dehydrating agent-2.

Embodiment 3

[0026] In the reactor, add 987kg of fresh water, start stirring, and add 2.85kg of anionic polyacrylamide. After completely dissolving, add 0.25kg sodium hydroxide (chemically pure) to adjust the pH value of the solution to 11-12. Then add 0.4g of disodium edetate (chemically pure), control the reaction temperature at 45°C, add 2500mL of formaldehyde (chemically pure), 2800mL of dimethylamine (chemically pure), and 1.62kg of sodium bisulfite into the reaction kettle , the reaction time is 3h. Finally, 4000 mL of hydrochloric acid (chemically pure) was added to stop the reaction to obtain the amphoteric dehydrating agent-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com