Preparation method and application of branched chain type wet strength agent

A wet strength agent and branched-chain technology, which is applied in the field of preparation of branched-chain wet strength agents, can solve the problems of entering white water, affecting the effective use rate and performance, and achieve good wet strength, excellent application performance and reaction temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

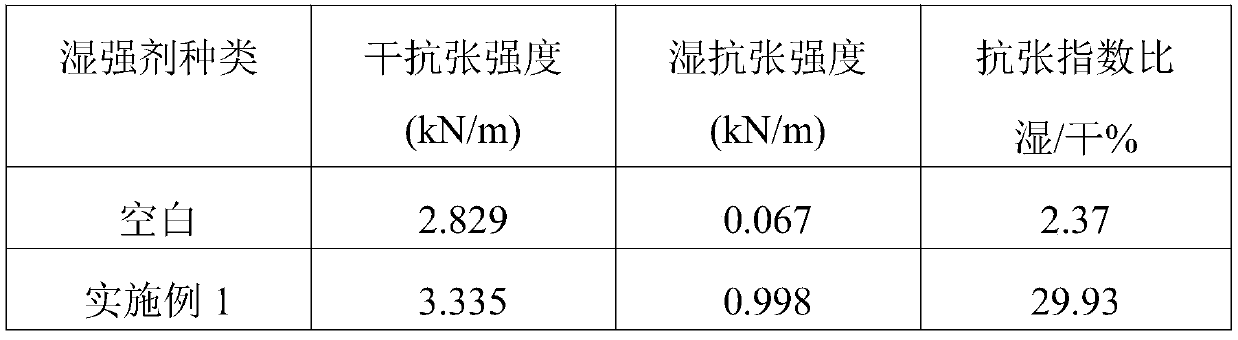

Embodiment 1

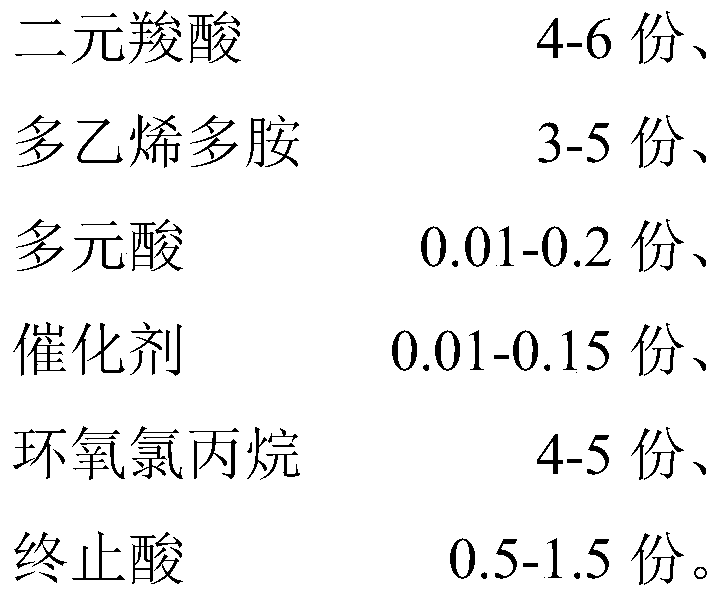

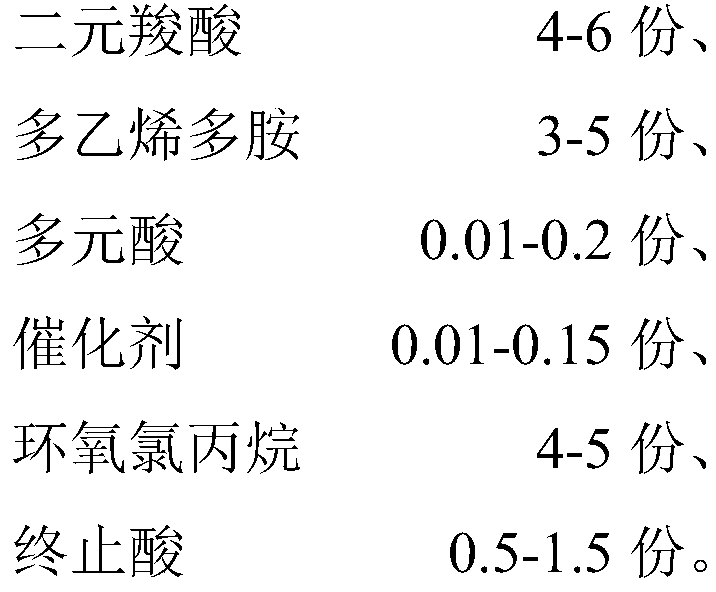

[0024] Preparation of branched high performance wet strength agent:

[0025] Add 20 grams of bottom water, 180 grams of diethylenetriamine, 260 grams of adipic acid and 1.5 grams of citric acid into the reaction kettle, stir and react for 1 hour, add 1.5 grams of catalyst concentrated sulfuric acid, stir and react for 1 hour, and then continue to heat up React at 165°C (reaction temperature is set according to actual needs) for 6 hours, add dilution water after the water output reaches the designed amount, and dilute the polymer to a solid content of 50%. Take 160 grams of the polymer solution, add 400 grams of water, stir evenly, add 45 grams of epichlorohydrin, control the reaction temperature below 50°C for 6 hours, add 50% dilute sulfuric acid to terminate the reaction when the viscosity of the reaction solution reaches the designed viscosity , add water to adjust the solid content to 12.5%, and add acid or alkali to adjust the pH to 3.5.

Embodiment 2

[0027] Preparation of branched high performance wet strength agent:

[0028] Add 30 grams of bottom water, 190 grams of diethylenetriamine, 270 grams of adipic acid and 2 grams of citric acid into the reaction kettle, stir and react for 1 hour, add 1 gram of catalyst concentrated sulfuric acid, stir and react for 1 hour, and then continue to heat up React for 5 hours at 160°C (the reaction temperature is set according to actual needs). After the water output reaches the designed amount, add dilution water to dilute the polymer to a solid content of 55%. Take 150 grams of the polymer solution, add 450 grams of water, stir evenly, add 48 grams of epichlorohydrin, control the reaction temperature below 50 ° C for 5 hours, add 50% dilute sulfuric acid to terminate the reaction when the viscosity of the reaction solution reaches the designed viscosity , add water to adjust the solid content to 12.5%, and add acid or alkali to adjust the pH to 3.0.

Embodiment 3

[0030] Preparation of branched high performance wet strength agent:

[0031] Add 20 grams of bottom water, 180 grams of diethylenetriamine, 260 grams of adipic acid and 1 gram of pyromellitic acid into the reaction kettle, stir and react for 1 hour, add 1.5 grams of catalyst p-toluenesulfonic acid, and stir and react for 1 hour , and then continue to heat up to 165°C (the reaction temperature is set according to actual needs) and react for 6 hours. After the water output reaches the designed amount, add dilution water to dilute the polymer to a solid content of 50%. Take 160 grams of the polymer solution, add 400 grams of water, stir evenly, add 45 grams of epichlorohydrin, control the reaction temperature below 50 ° C for 6 hours, add acetic acid to terminate the reaction when the viscosity of the reaction solution reaches the designed viscosity, and add water to adjust Solid content to 12.5%, while adding acid or alkali to adjust the pH to 3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com