Liquid organic high polymer coagulant and preparation method thereof

An organic polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of low effective content of products and cumbersome process, and achieve no unpleasant smell, complete production reaction, and enhanced charge density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

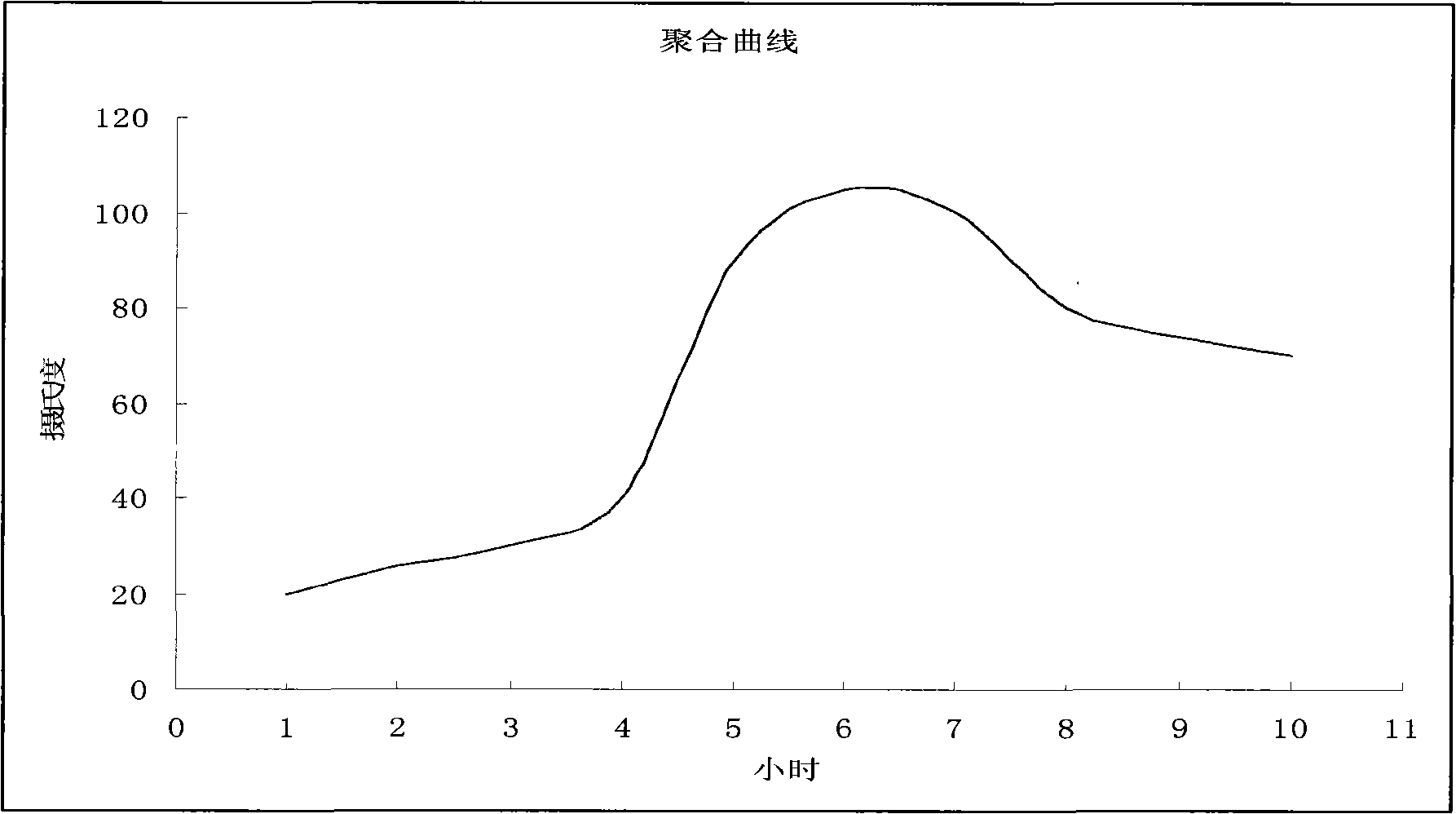

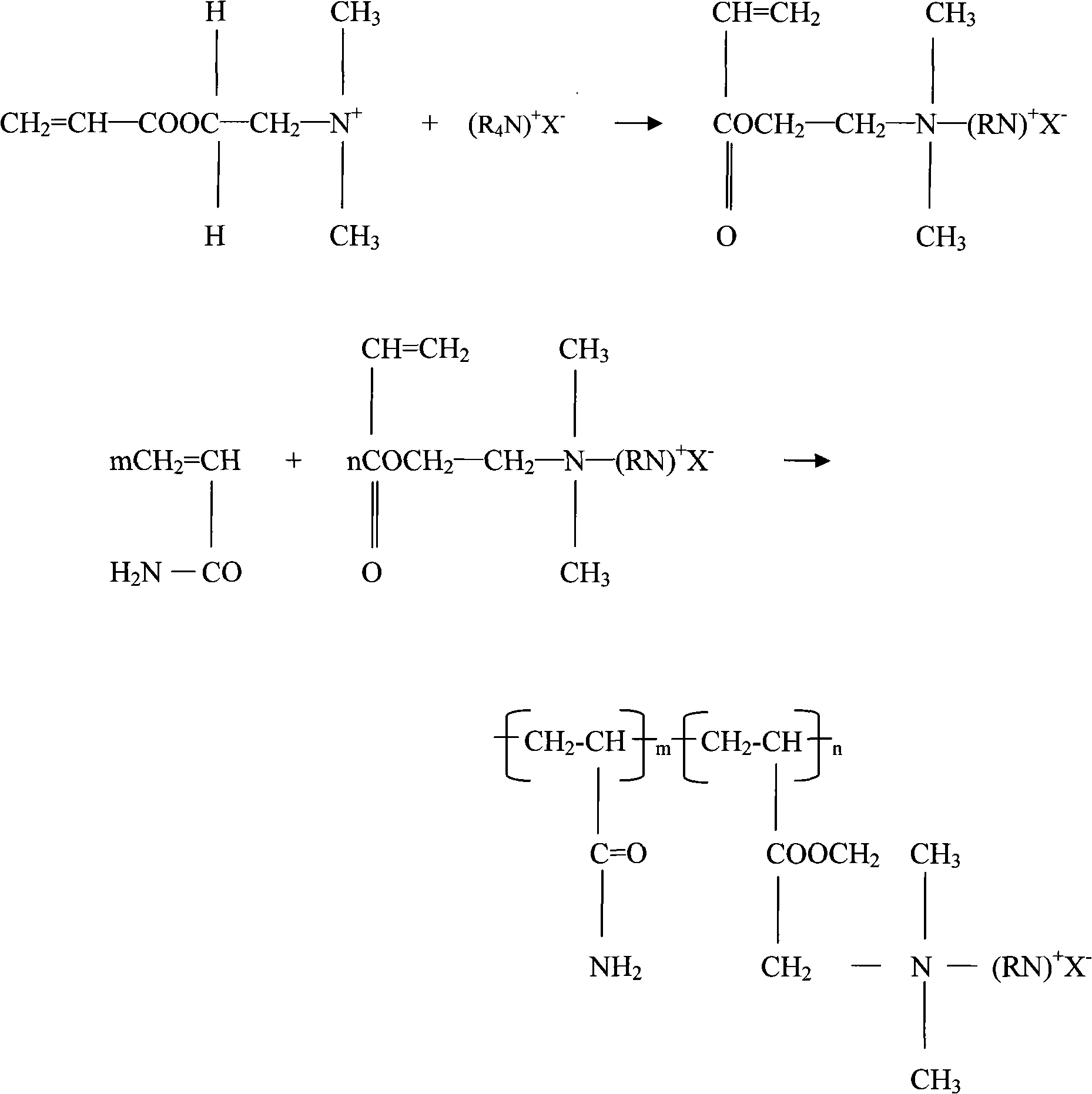

[0057] Fully dissolve dimethylaminoethyl acrylate in distilled water with a pH of 4, add quaternary ammonium salt, the molar ratio of quaternary ammonium salt to dimethylaminoethyl acrylate is 1:5; keep the temperature at 20-40°C by circulating cooling, stir The reaction is complete in 3 hours, and the temperature is raised to 90°C within 1 hour. At the same time, nitrogen gas is introduced to eliminate the interference of oxygen, and acrylamide monomer, emulsified oil and initiator are added to carry out polymerization reaction. The mixture of acrylamide monomer and dimethylaminoethyl acrylate The molar ratio is 1:8, the ratio of acrylamide, quaternary ammonium salt and dimethylaminoethyl acrylate is 20% of the total output, the emulsified oil addition is 0.1kg / L, and the initiator addition is 0.01mol / L. Stir continuously for 2 hours at a temperature of 95-105°C;

[0058] The consumption of distilled water whose pH is 4 is 60% of output;

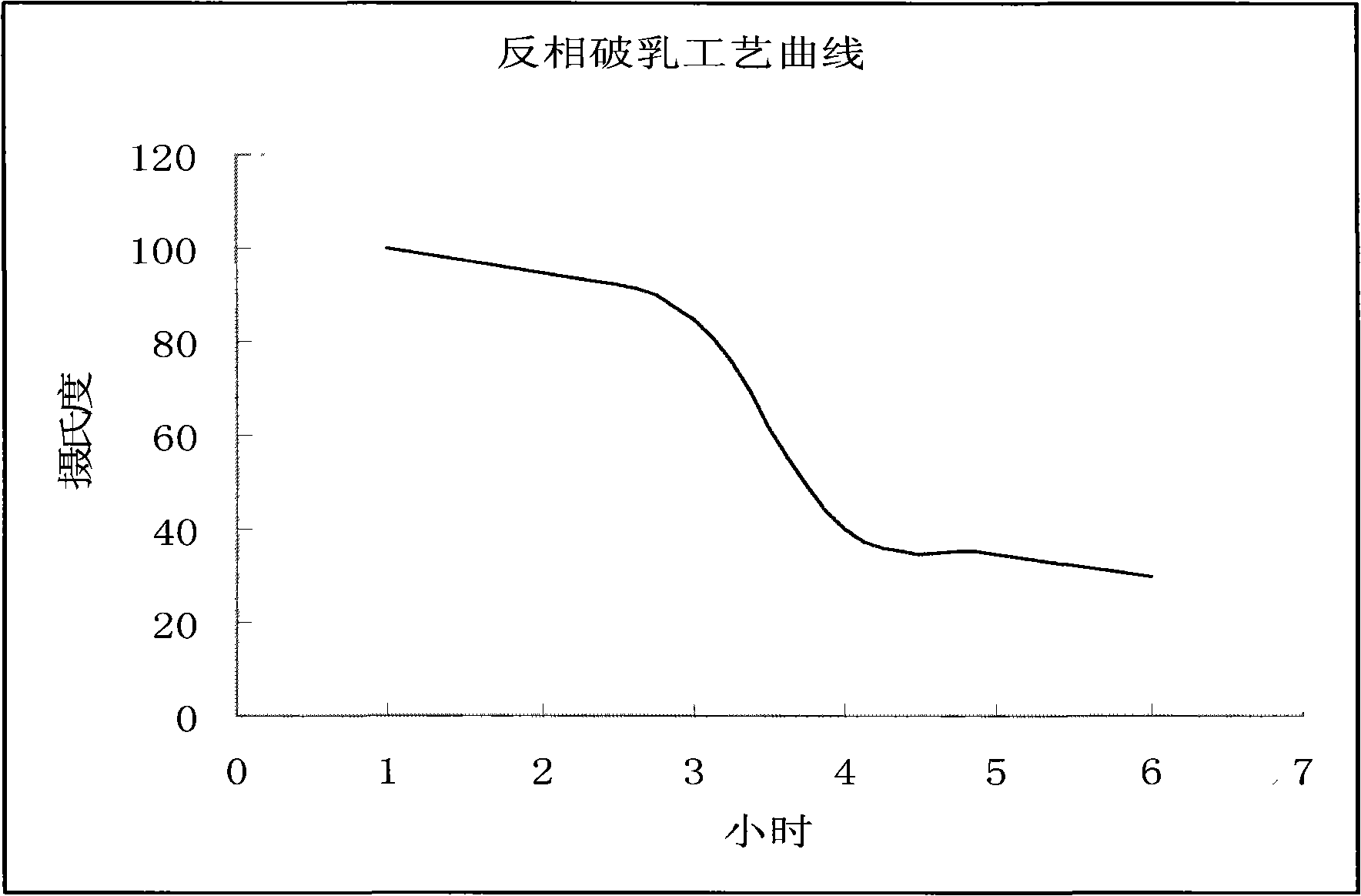

[0059] After the end of the reactio...

Embodiment 2

[0067] Fully dissolve dimethylaminoethyl acrylate in distilled water with a pH of 6, add quaternary ammonium salt, the molar ratio of quaternary ammonium salt to dimethylaminoethyl acrylate is 5:1; keep the temperature at 20-40°C by circulating cooling, stir The reaction is complete in 3 hours, and the temperature is raised to 90°C within 1 hour. At the same time, nitrogen gas is introduced to eliminate the interference of oxygen, and acrylamide monomer, emulsified oil and initiator are added to carry out polymerization reaction. The mixture of acrylamide monomer and dimethylaminoethyl acrylate The molar ratio is 8: 1, the ratio of acrylamide, quaternary ammonium salt and dimethylaminoethyl acrylate is 50% of the total output, the amount of emulsified oil added is 0.1kg / L, and the amount of initiator added is 0.01mol / L. Stir continuously for 2 hours at a temperature of 95-105°C;

[0068] The amount of distilled water with a pH of 6 is determined according to the final product ...

Embodiment 3

[0077] Fully dissolve dimethylaminoethyl acrylate in distilled water with a pH of 5, add quaternary ammonium salt, the molar ratio of quaternary ammonium salt to dimethylaminoethyl acrylate is 1:1; keep the temperature at 20-40°C by circulating cooling, stir The reaction is complete in 3 hours, and the temperature is raised to 90°C within 1 hour. At the same time, nitrogen gas is introduced to eliminate the interference of oxygen, and acrylamide monomer, emulsified oil and initiator are added to carry out polymerization reaction. The mixture of acrylamide monomer and dimethylaminoethyl acrylate The molar ratio is 1: 3, the ratio of acrylamide, quaternary ammonium salt and dimethylaminoethyl acrylate is 40% of the total output, the emulsified oil addition is 0.1kg / L, and the initiator addition is 0.01mol / L. Stir continuously for 2 hours at a temperature of 95-105°C;

[0078] The consumption of the distilled water whose pH is 5 is 40%.

[0079] After the end of the reaction, qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com