Attapulgite sewage water treating method

A sewage treatment method, the technology of attapulgite, applied in the field of sewage treatment, can solve the problems of high cost, slow speed, unfavorable cost accounting, etc., and achieve the effect of low cost, time saving and equipment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

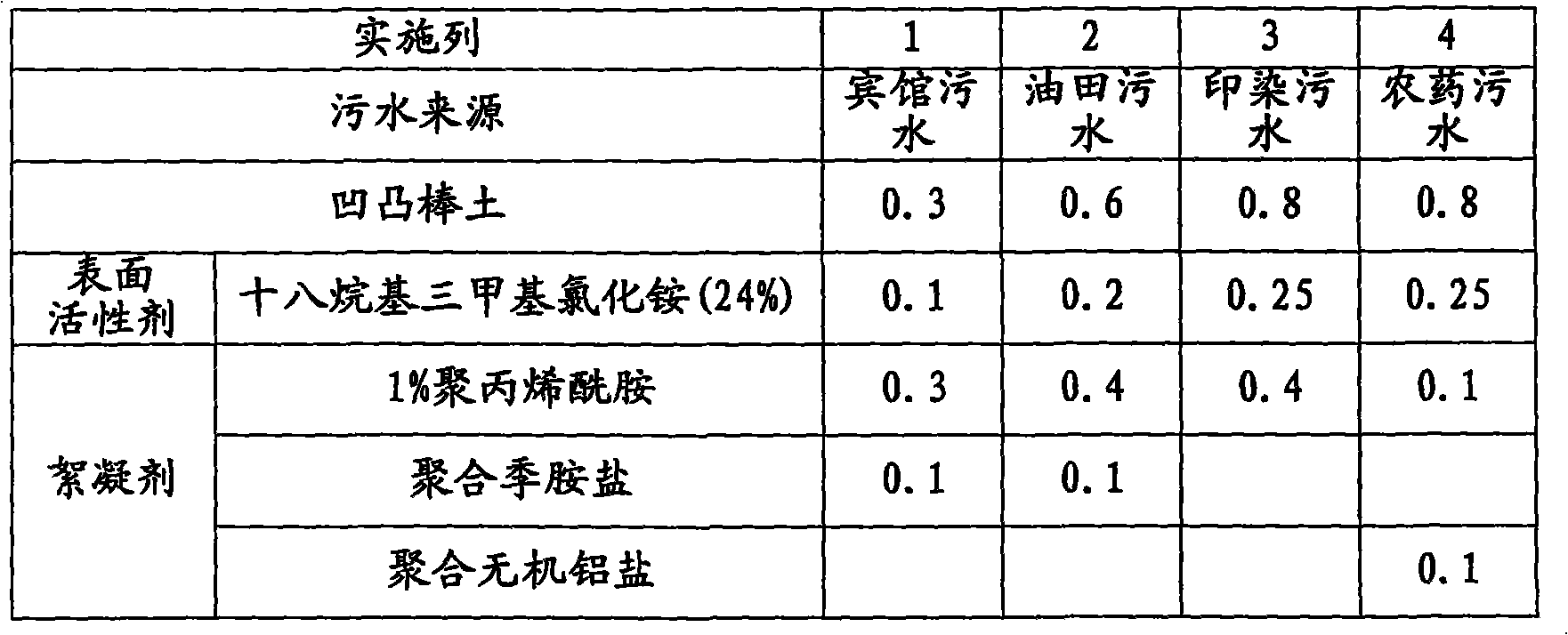

[0007] The present invention will be described in further detail below in conjunction with the examples: the following table is the ratio of attapulgite, surfactant, flocculant raw materials and kilograms required for each ton of sewage purification treatment.

[0008]

[0009] Now take the hotel sewage as an example to explain its treatment method: first calculate the total sewage by the volume of the sewage tank, and then compare the raw materials and kilograms of the hotel sewage in Example 1 in the table: Add 0.3kg of attapulgite per ton of sewage and stir. For 15 minutes, add 0.1 kg of octadecyl trimethyl ammonium chloride with a concentration of 24%, stir for 30 minutes, add 0.3 kg of polyacrylamide with a concentration of 1% and 0.1 kg of polymeric quaternary salt, and stir for 15 minutes. , Settling for 30 minutes, the upper clear liquid is pumped out with a pump, and the lower sediment is dewatered with a centrifuge or a plate and frame filter press. If further purifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com