Water-soluble polyurethane dispersoid slurry and method for preparing wet method base thereof

A water-based polyurethane and dispersion technology, which is applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problems of inability to meet consumers' high requirements for synthetic leather products, slow resin drying speed, and low process efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

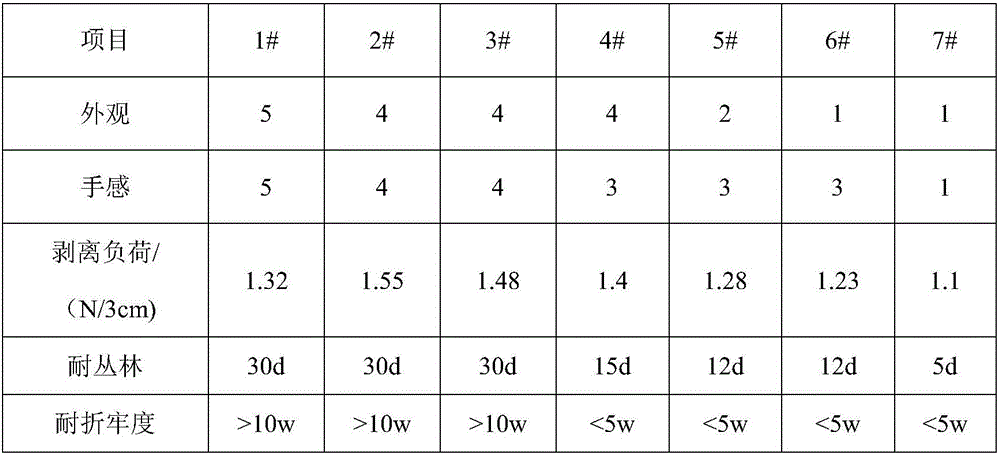

Embodiment 1

[0086] (1) 91.8g of 3288, 2g of Stokal STA, 2g of Stokal SR, 0.8g of Vesmody U605, 0.4g of Vesmody U300, and 3g of Aquolin 161 were stirred at 1000r / min for 2 hours and mixed evenly. When the time is 2 times, use the scraping method to scrape the foamed water-based polyurethane dispersion slurry on the treated base fabric, and the scraping thickness is 0.8mm. Get a semi-finished bass.

[0087] (2) Bass semi-finished products are immersed in the flocculation solution for 5 minutes, then put into the water tank for 3 minutes, and then dried in a blast oven at 110°C. Get 1# bass finished product.

Embodiment 2

[0089] (1) Preparation of aqueous polyurethane dispersion:

[0090] in dry N 2 Under protection, in the four-necked flask that thermometer, condenser tube and stirring paddle are housed, add successively into 75g dicyclohexylmethane diisocyanate (H 12 MDI), 100g polypropylene glycol (average molecular weight is 2000), 100g polytetrahydrofuran diol (average molecular weight is 2000), be heated up to 80 ℃, react 1 hour at 80 ℃ ± 2 ℃, when temperature drops below 60 ℃, to Add 1.5g N120, 5.8g dimethylolpropionic acid, 5.8g neopentyl glycol, 30g acetone in the four-necked flask, heat up to 80°C for reaction, reach NCO (2.27wt%) and then cool down to stop the reaction; when the temperature drops to 55°C, add 290g of acetone to the flask to dilute the prepolymer, continue to cool down to room temperature, add 4.37g of triethylamine for neutralization reaction, neutralization reaction time is 5min; after neutralization, cool down to room temperature, add 15g of deionized water Dilut...

Embodiment 3

[0093] (1) Preparation of aqueous polyurethane dispersion:

[0094] in dry N 2 Under protection, in the four-neck flask that thermometer, condenser tube and stirring paddle are housed, add successively into 100g dicyclohexylmethane diisocyanate (H 12MDI), 120g polypropylene glycol (average molecular weight is 2000), 100g polytetrahydrofuran diol (average molecular weight is 2000), be heated up to 80 ℃, react 1 hour at 80 ℃ ± 2 ℃, when temperature drops below 60 ℃, to Add 1.5g N120, 9g dimethylolpropionic acid, 9g neopentyl glycol, and 40g acetone into the four-necked flask, heat up to 80°C for reaction, and cool down to stop the reaction after NCO reaches 2.58wt%; when the temperature drops to 50°C, Add 338g of acetone to the flask to dilute the prepolymer, continue to cool down to room temperature, add 6.78g of triethylamine for neutralization reaction, neutralization reaction time is 5min; after neutralization, cool down to room temperature, add 4.5 g ethylenediamine, 35°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com