Powdery high-whiteness polyaluminium chloride complex and preparation method thereof

A technology of polyaluminum chloride and compound, which is applied in the field of powdery high-whiteness polyaluminum chloride compound and its preparation, which can solve the problems of small dosage not meeting flocculation requirements, poor flocculation and bridging ability, and reduction of whiteness of white paper and other problems, to achieve good flocculation and sedimentation effect, strong flocculation ability, and improve the whiteness of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

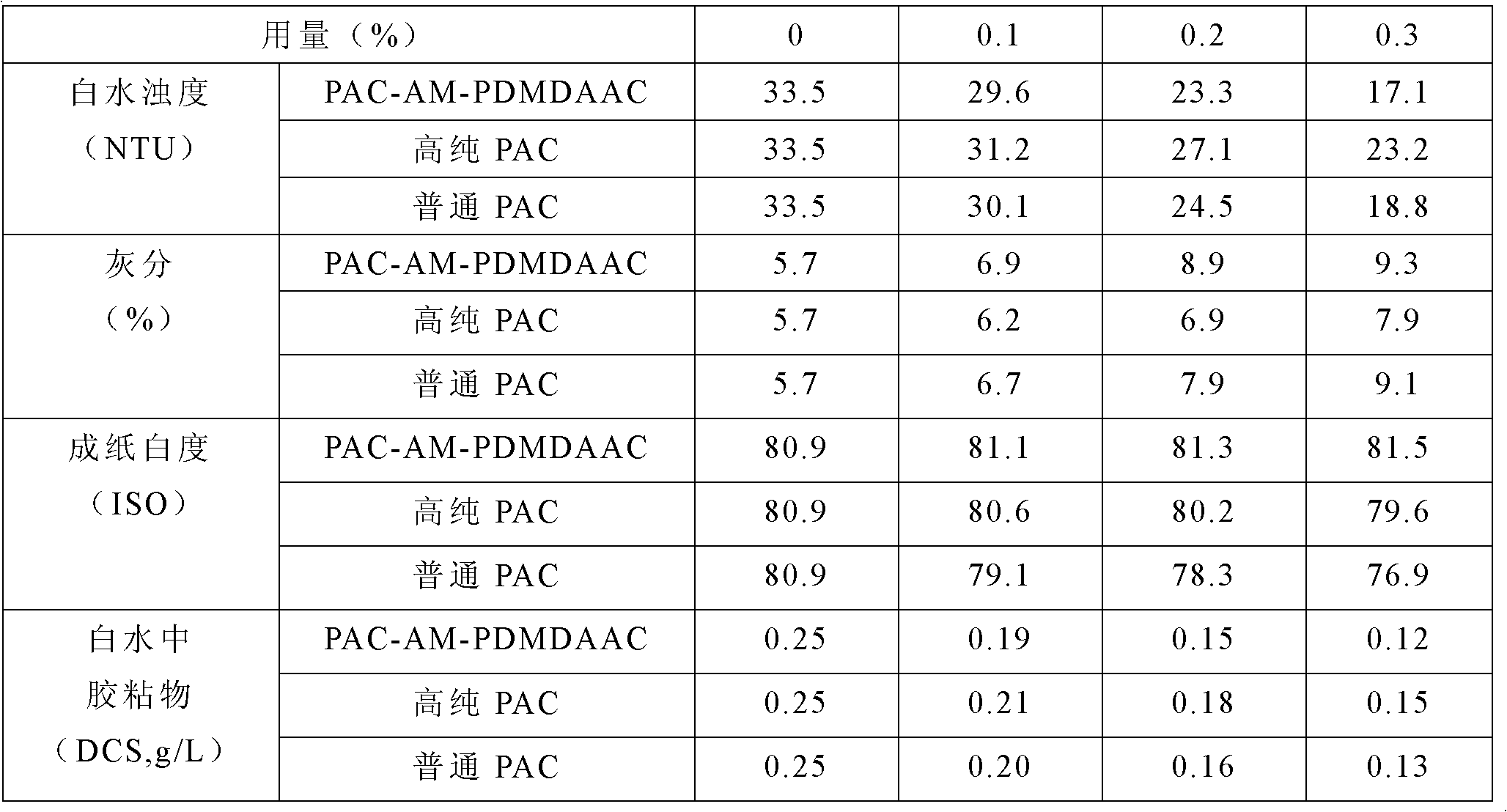

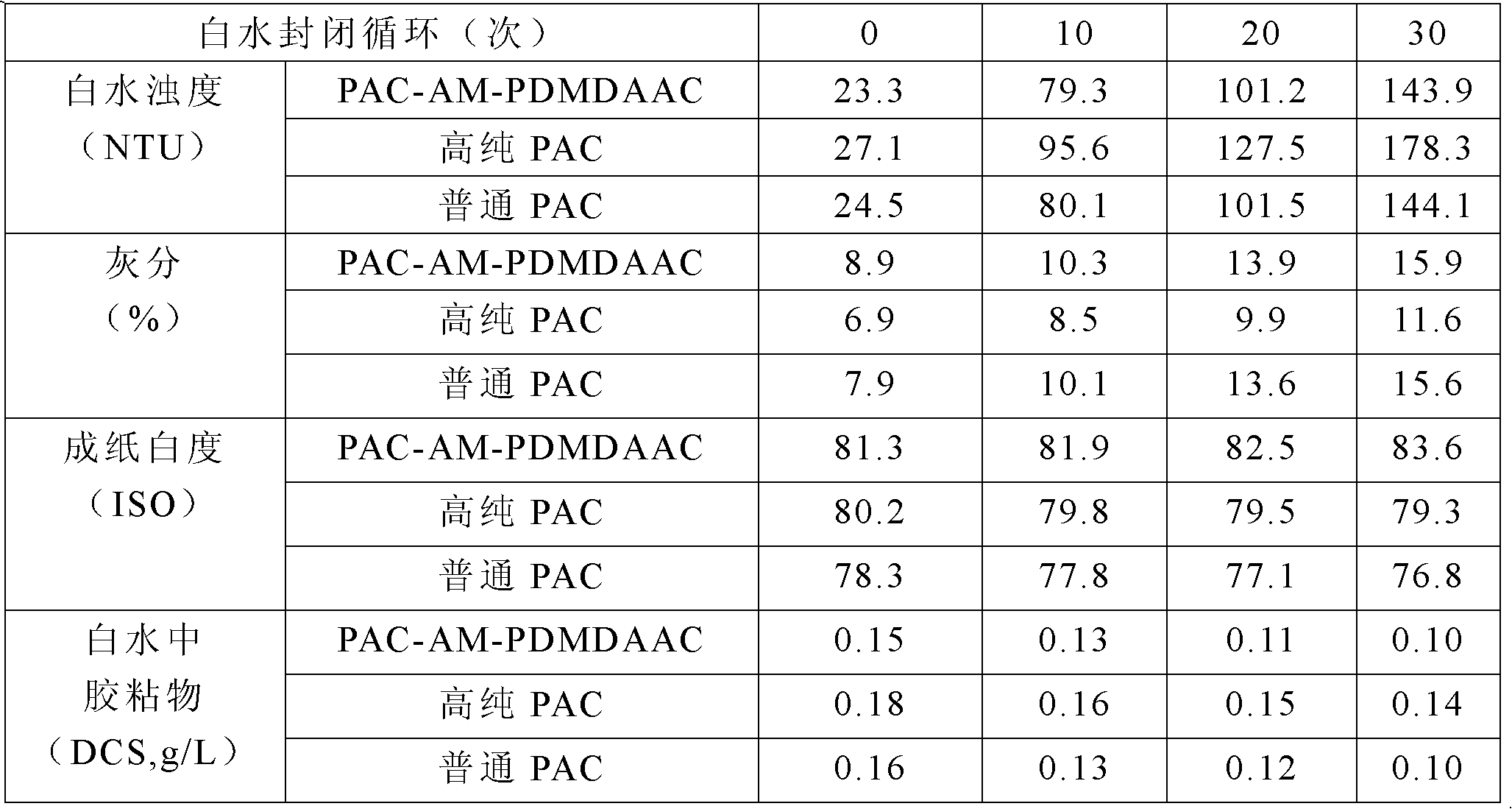

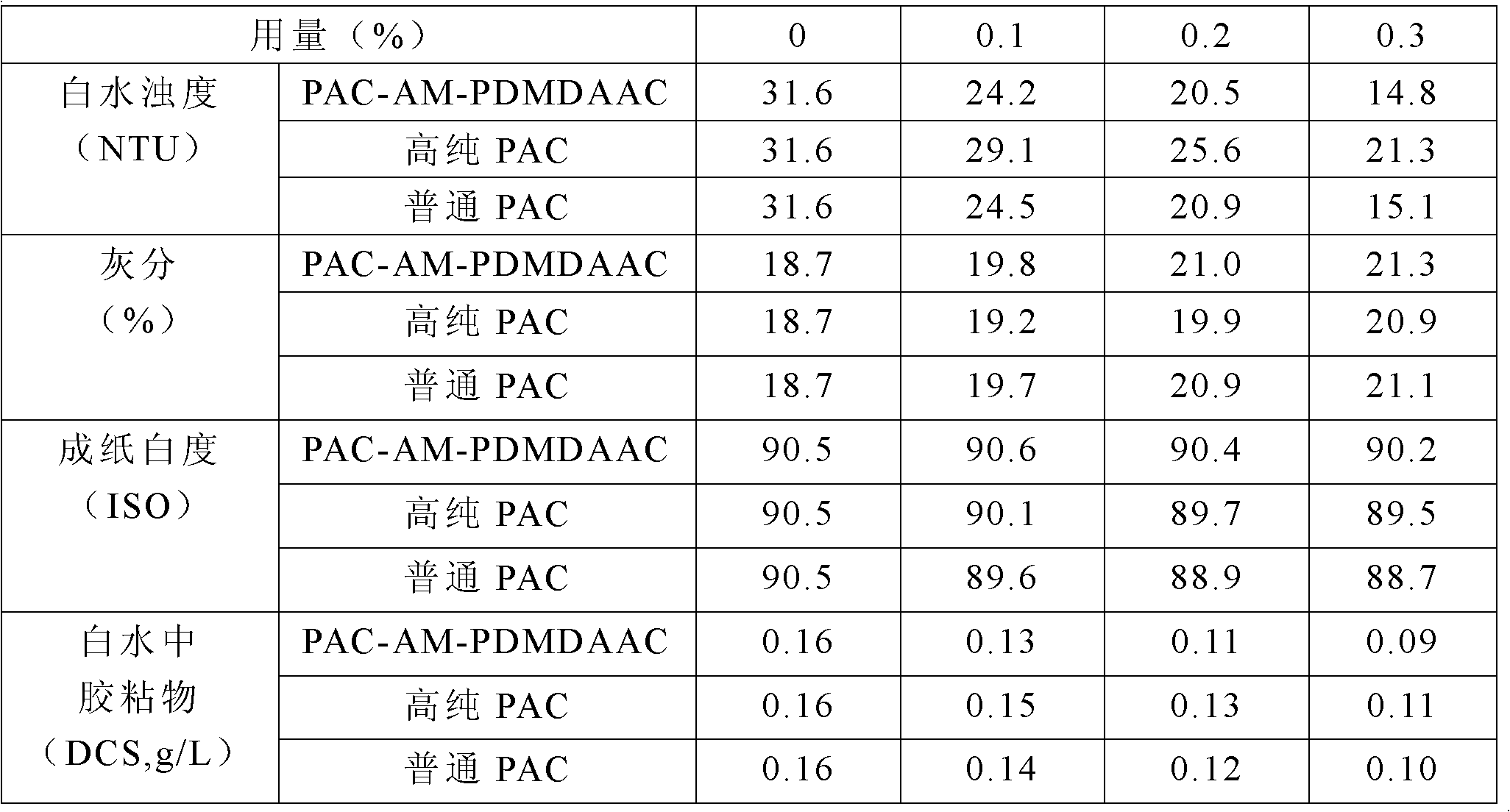

Examples

Embodiment 1

[0019] 1. Preparation of powdery PAC-AM-PDMDAAC complex

[0020] (1) Preparation of liquid polyaluminum chloride: Add 200g of aluminum hydroxide with a mass content of 64.5% of alumina and 500g of high-purity hydrochloric acid with a mass content of 31% of hydrogen chloride in an enamel kettle, and the reaction temperature is 150-155°C , react at a stirring speed of 250-300 rpm for 5 hours, then cool down to 95°C, add 30g of high-purity aluminum flakes, continue the reaction for 30 minutes, then add 35g of sodium aluminate, calcium carbonate or calcium hydroxide for 30 minutes Minutes, filter, remove filter residue, obtain alkalization degree and be 75%, the liquid polyaluminum chloride that aluminum oxide content is 15%;

[0021] (2), the preparation of acrylamide-dimethyl diallyl ammonium chloride copolymer: add 300g solid content to be 40% acrylamide solution and 33g solid content to be 60% dimethyl Base diallyl ammonium chloride solution, feed nitrogen for 15 minutes, dri...

Embodiment 2

[0036] 1. Preparation of powdery PAC-AM-PDMDAAC complex

[0037] (1), the preparation of liquid polyaluminum chloride: add 200g aluminum oxide mass content and be 64.5% soluble aluminum hydroxide and 460g hydrogen chloride mass content in enamel still, be the high-purity hydrochloric acid of 31%, at reaction temperature be 150~ React for 5 hours at 155°C with a stirring speed of 250-300 rpm, then cool down to 100°C, add 20g of high-purity aluminum flakes, continue to react for 50 minutes, then add 60g of calcium carbonate, react for 40 minutes, filter, remove filter residue, the degree of alkalization obtained is 85%, and the aluminum oxide content is 15% liquid polyaluminum chloride;

[0038] (2), the preparation of acrylamide-dimethyl diallyl ammonium chloride copolymer: add 400g solid content to be 40% acrylamide solution and 45g solid content to be 60% dimethyl Base diallyl ammonium chloride solution, feed nitrogen for 15 minutes, drive away the oxygen in the reactor, the...

Embodiment 3

[0054] 1. Preparation of powdery PAC-AM-PDMDAAC complex

[0055] (1), the preparation of liquid polyaluminum chloride: add 200g aluminum oxide mass content and be 64.5% soluble aluminum hydroxide and 460g hydrogen chloride mass content in enamel still, be the high-purity hydrochloric acid of 31%, at reaction temperature be 150~ 155°C, react at a stirring speed of 250-300 rpm for 5 hours, then cool down to 90°C, add 20g of high-purity aluminum flakes, continue the reaction for 50 minutes, then add 30g of aluminum sulfate or polyaluminum sulfate, and stir for 20 Filter after 10 minutes, remove filter residue, obtain alkalization degree and be 55%, the liquid polyaluminum chloride that aluminum oxide content is 15%;

[0056] (2), the preparation of acrylamide-dimethyl diallyl ammonium chloride copolymer: in the there-necked flask with reflux, add the acrylamide solution that 500g solid content is 40% and 67g solid content are 60% dimethyl Base diallyl ammonium chloride solution, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com