Method for decoloring burned waste water by using zero-valent iron/ultrasonic wave synergistic reaction

A synergistic, zero-valent iron technology, applied in the field of environmental chemistry, to achieve the effect of improving biodegradability and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

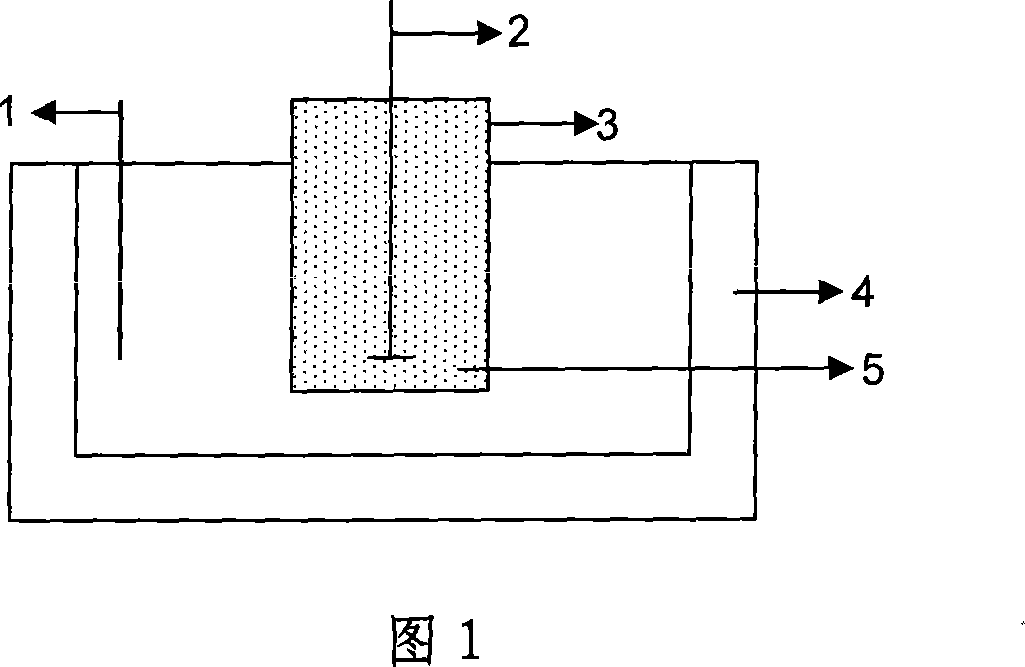

[0020] The reactor 3 is placed in an ultrasonic cleaner 4, the reactor 3 is provided with a stirrer 2, and the thermometer 1 is placed in the ultrasonic cleaner 4 to measure the reaction temperature.

[0021] Add 1.0L of waste water and 50g of zero-valent iron powder into the reactor, wherein the properties of the zero-valent iron are: nanoscale iron powder, its purity > 99%, the particle size is 35nm, and the specific surface area is 120m 2 / g; use hydrochloric acid to adjust the pH to 3.0, and then stir the reaction for 30 minutes at an ultrasonic power of 150W and a temperature of 30°C to achieve decolorization of wastewater and COD removal (see Table 1 for decolorization effect).

[0022] Table 1 Comparison of coking wastewater treated by ultrasonic / zero-valent iron synergistic system

[0023]

[0024] It can be seen from Table 1 that the ultrasonic wave / zero-valent iron synergy of the present invention is adopted, and the chromaticity of waste water is reduced f...

Embodiment 2

[0026] The difference from Example 1 is that 1.0L of waste water and 100g of zero-valent iron powder are added to the reactor, wherein the physical properties of the zero-valent iron are: micron-sized iron powder with a purity of 99% and a particle size of 0.04mm , the specific surface area is 1.0m 2 / g; use hydrochloric acid to adjust the pH to 1.0, and then stir and react for 20 minutes at an ultrasonic power of 160W and a temperature of 50°C to achieve decolorization of wastewater and COD removal (see Table 2 for decolorization effect).

[0027] Zero-valent iron / ultrasonic synergistic effect on decolorization of coking wastewater

[0028] It can be seen from Table 2 that increasing the reaction temperature, the amount of zero-valent iron, the ultrasonic power and reducing the initial pH of the wastewater will improve the decolorization effect of the wastewater: the color of the treated wastewater is only 100, and its BOD 5 When the / COD value is increased to 0.38,...

Embodiment 3

[0030] The difference from Example 1 is that 1.0L of waste water and 2g of zero-valent iron powder are added to the reactor, and the zero-valent iron is nano-scale iron powder with a purity of 99%, a particle size of 100nm, and a specific surface area of 70m 2 / g; use hydrochloric acid to adjust the pH to 6, and then stir and react for 120 minutes at an ultrasonic power of 200W and a temperature of 10°C to achieve wastewater decolorization and COD removal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com