Green utilization method of waste acid

A polluted acid and green technology, applied in the chemical and metallurgical fields, can solve the problems of difficult extraction of gypsum, long industrial process, waste of resources, etc., and achieve the effects of cost reduction, short process flow and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

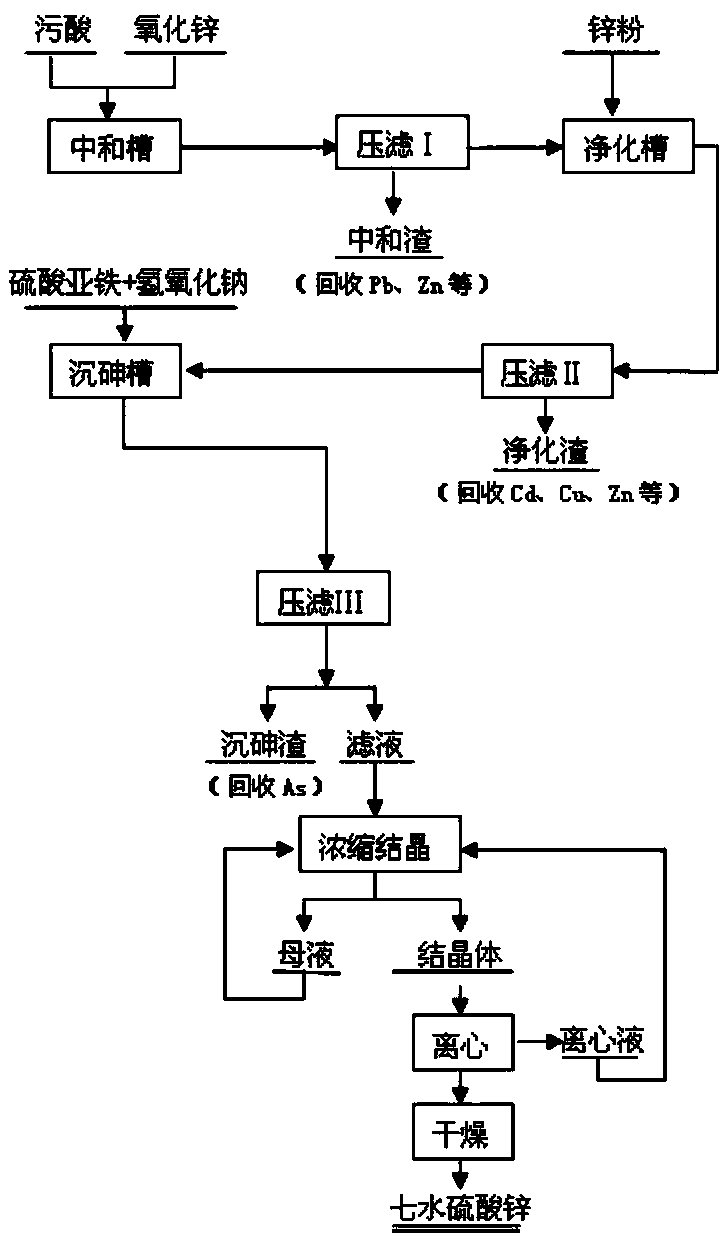

Image

Examples

Embodiment 1

[0021] (1) Put 2 m of dirty acid into the neutralization tank 3 , Add 300 kg of zinc oxide powder into the neutralization tank, control the pH value of the neutralization tank to 4, and the temperature to 42°C, and keep stirring to make it fully react.

[0022] (2) The neutralized slag after being filtered by the filter press is sent to the next stage of the process to recover the valuable metals, and the neutralized liquid is introduced into the purification tank.

[0023] (3) After the neutralized liquid enters the purification tank, keep a constant temperature of 45°C, add 2 kg of zinc powder into the purification tank, and keep stirring to make it fully react.

[0024] (4) The purified slag after being filtered by the filter press is sent to the next stage of the process to recover the valuable metals in it, and the purified liquid is introduced into the arsenic sink.

[0025] (5) After the purified liquid enters the arsenic precipitation tank, add 80 kg of ferrous sulfat...

Embodiment 2

[0029] (1) Put 4 m of dirty acid into the neutralization tank 3 , Add 900 kg of zinc oxide powder into the neutralization tank, control the pH value of the neutralization tank to 5, and the temperature to 43°C, and keep stirring to make it fully react.

[0030] (2) The neutralized slag after being filtered by the filter press is sent to the next stage of the process to recover the valuable metals, and the neutralized liquid is introduced into the purification tank.

[0031] (3) After the neutralized liquid enters the purification tank, keep a constant temperature of 48°C, add 6 kg of zinc powder into the purification tank, and keep stirring to make it fully react.

[0032] (4) The purified slag after being filtered by the filter press is sent to the next stage of the process to recover the valuable metals in it, and the purified liquid is introduced into the arsenic sink.

[0033] (5) After the purified liquid enters the arsenic precipitation tank, add 300 kg of ferrous sulfa...

Embodiment 3

[0037] (1) Put 10 m of dirty acid into the neutralization tank 3 , Add 2000 kg of zinc oxide powder into the neutralization tank, control the pH value of the neutralization tank to 6, and the temperature to 45°C, and keep stirring to make it fully react.

[0038] (2) The neutralized slag after being filtered by the filter press is sent to the next stage of the process to recover the valuable metals, and the neutralized liquid is introduced into the purification tank.

[0039] (3) After the neutralized liquid enters the purification tank, keep a constant temperature of 50°C, add 20 kg of zinc powder into the purification tank, and keep stirring to make it fully react.

[0040] (4) The purified slag after being filtered by the filter press is sent to the next stage of the process to recover the valuable metals in it, and the purified liquid is introduced into the arsenic sink.

[0041] (5) After the purified liquid enters the arsenic sink, add 1,000 kg of ferrous sulfate solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com