Integrated oxidation ditch, construction and operation method

An operation method and oxidation ditch technology, applied in the field of sewage treatment, can solve problems such as unsatisfactory degree of reasonable coordination, uncoordinated sludge discharge cycle, insufficient denitrifying carbon source, etc., saving capital investment and operating costs, and facilitating construction management. , the effect of sufficient denitrification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

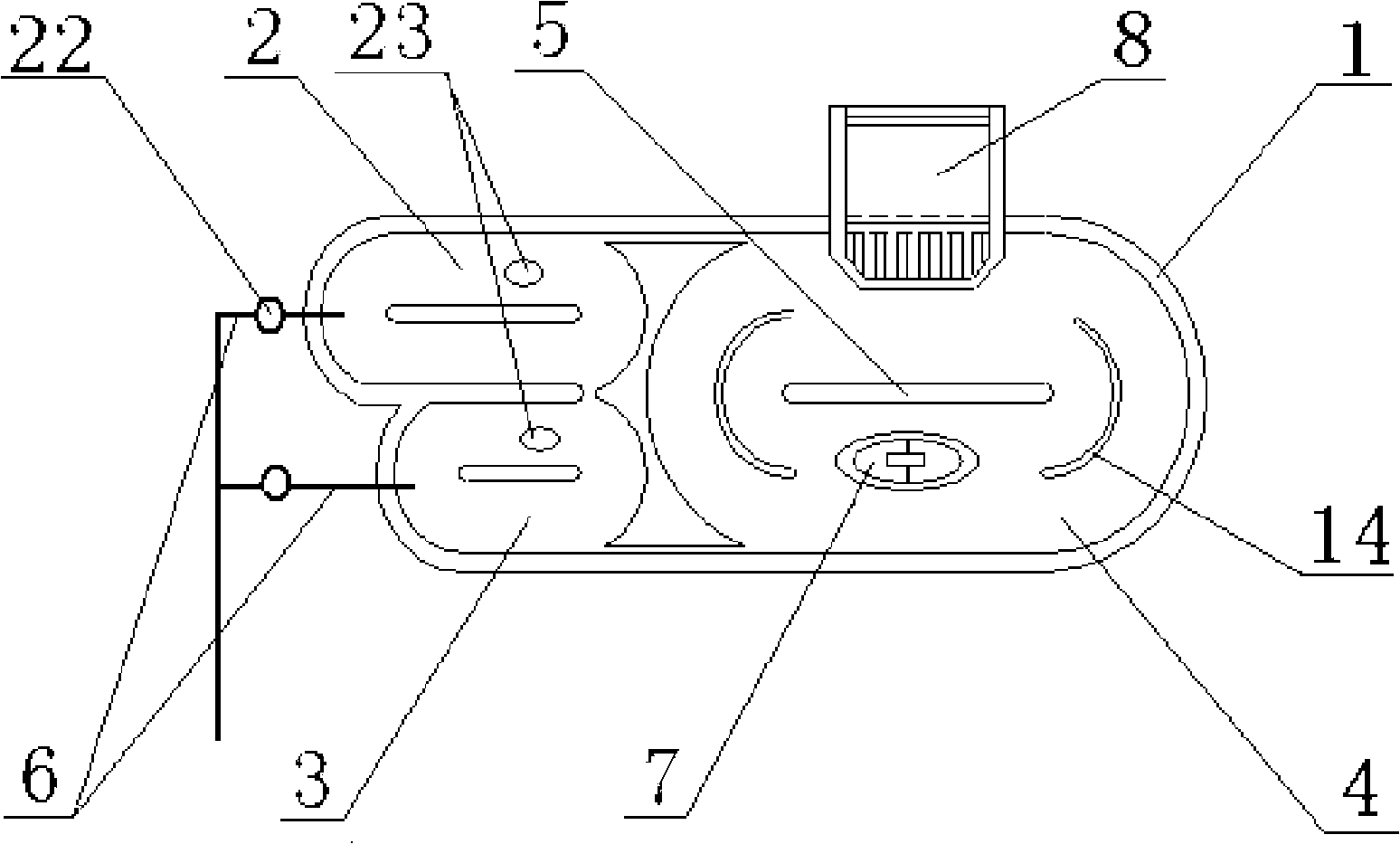

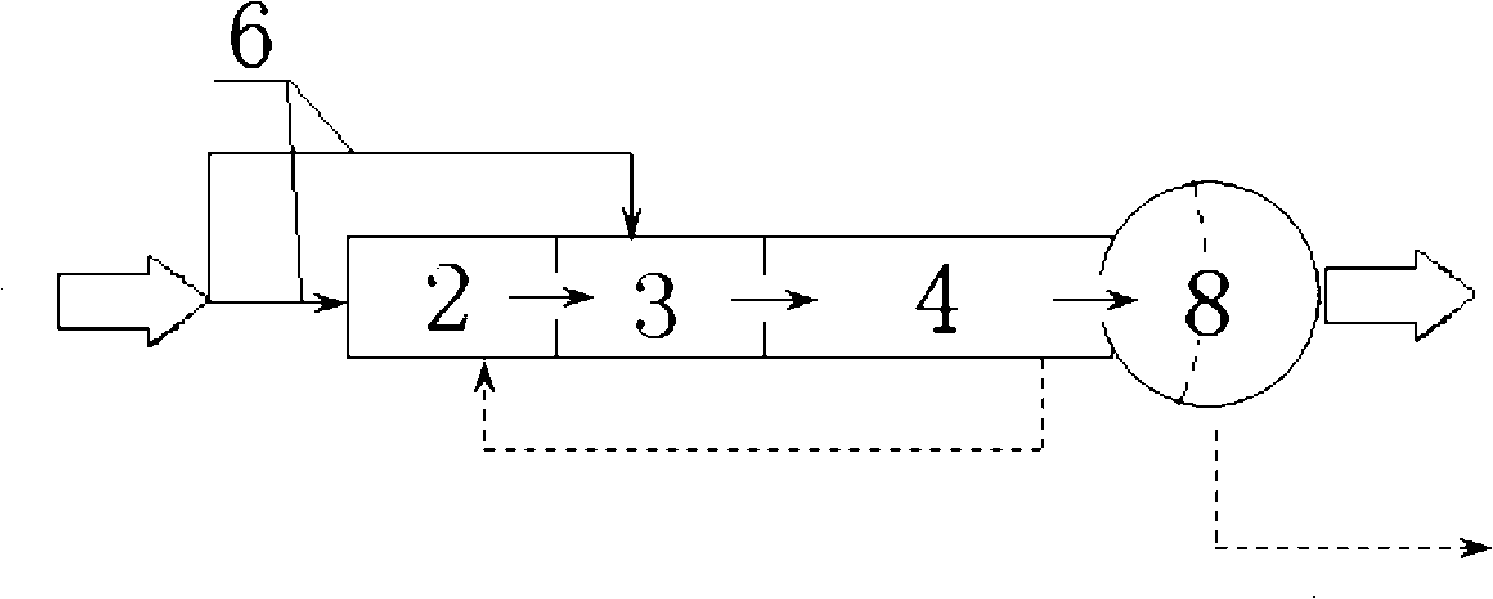

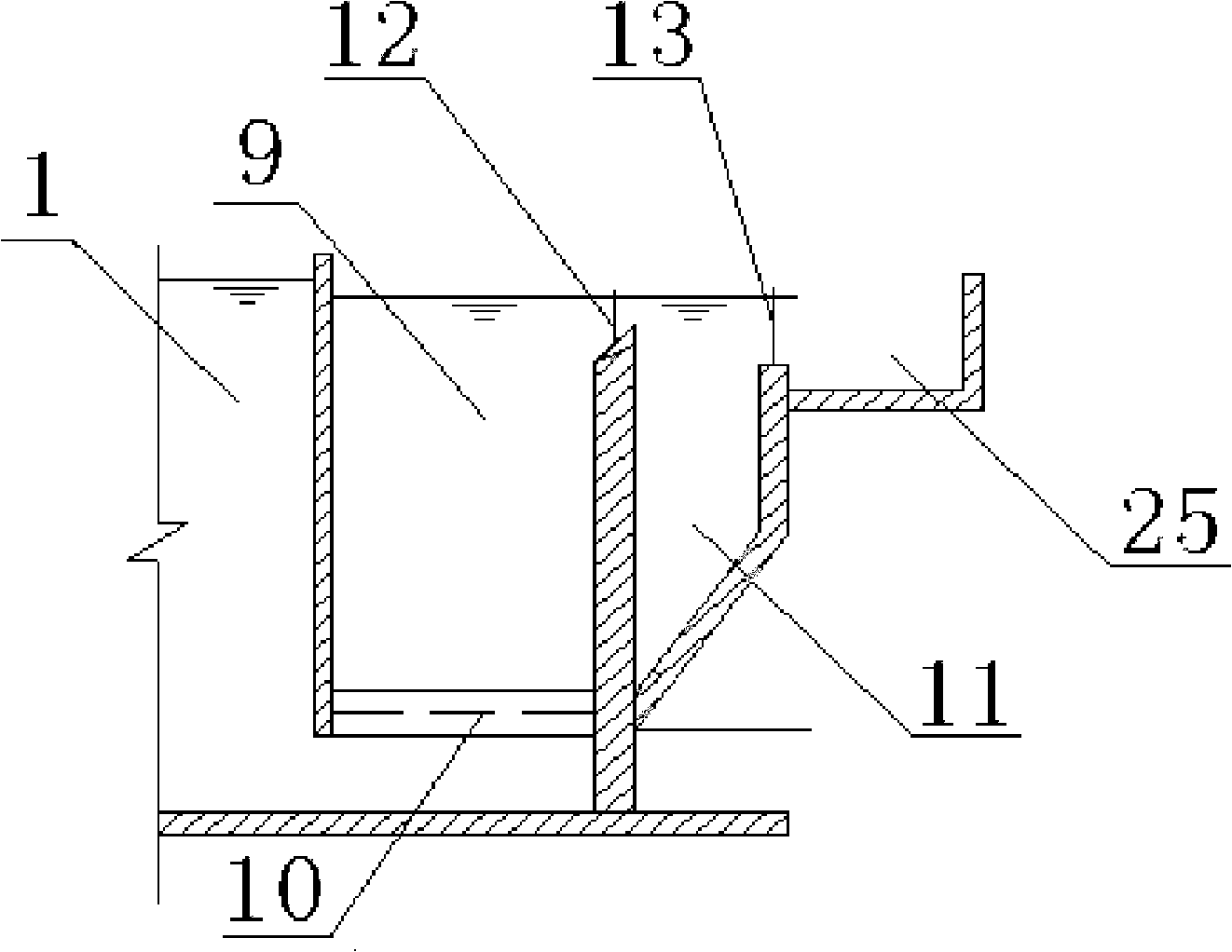

Embodiment 1

[0023] Embodiment 1 of the present invention: the construction method of this integrated oxidation ditch is: it comprises the existing integrated oxidation ditch that is used for sewage treatment, and the integrated oxidation ditch is divided into interconnected anoxic zone, anaerobic zone, aerobic zone The anoxic zone and the anaerobic zone are set at one end of the integrated oxidation ditch, and the aerobic zone is set at the other end, and a water barrier is installed in the middle of each zone (the water barrier can be made of stainless steel plate and other existing materials). There are commercially available waterproof boards, or use brick walls built on site to achieve the same purpose), so that each zone forms a separate annular flow channel, and it is installed in the anoxic zone and anaerobic zone for point-by-point injection The inlet pipe of water is installed in the circulation channel of the side of the aerobic zone connected with the anaerobic zone (the aeratio...

Embodiment 2

[0027] Embodiment 2 of the present invention: the construction method of this integrated oxidation ditch is: it comprises the existing integrated oxidation ditch that is used for sewage treatment, and the integrated oxidation ditch is divided into interconnected anoxic zone, anaerobic zone, aerobic zone The anoxic zone and the anaerobic zone are set at one end of the integrated oxidation ditch, and the aerobic zone is set at the other end, and a water barrier is installed in the middle of each zone (the water barrier can be made of stainless steel plate and other existing materials). There are commercially available waterproof boards, or use brick walls built on site to achieve the same purpose), so that each zone forms a separate annular flow channel, and it is installed in the anoxic zone and anaerobic zone for point-by-point injection The inlet pipe of water is installed in the circulation channel of the side of the aerobic zone connected with the anaerobic zone (the aeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com