Full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine

A screen printing machine and screen printing technology, applied to screen printing machines, rotary printing machines, printing machines, etc., can solve the problems of unstable printing quality and slow printing speed, and achieve easy debugging, good printing effect, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

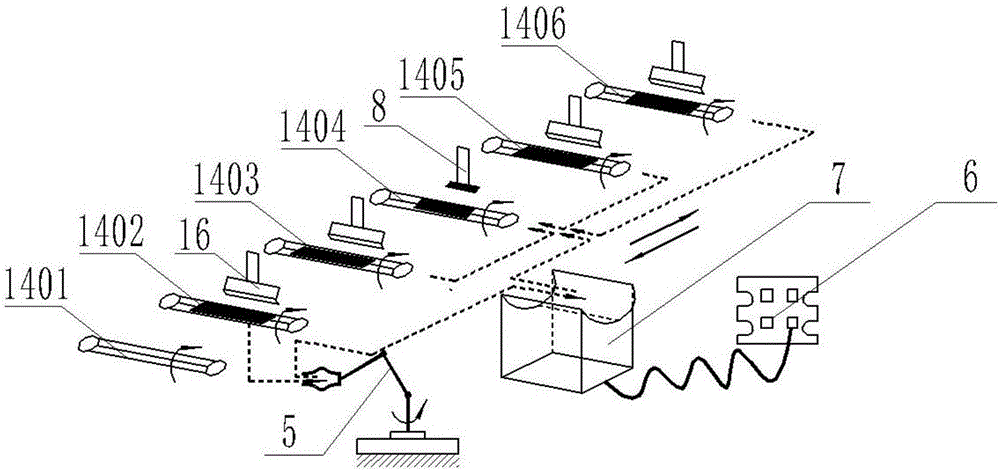

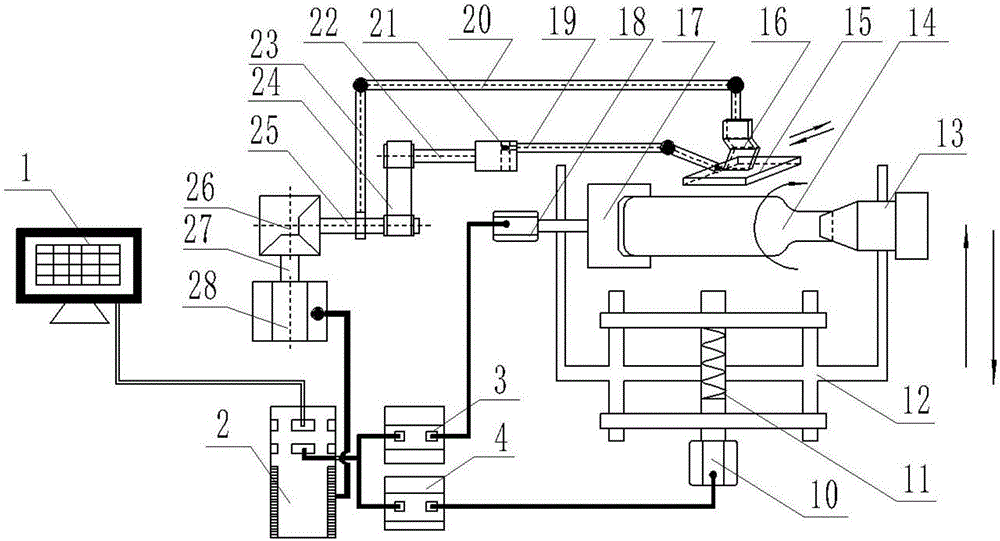

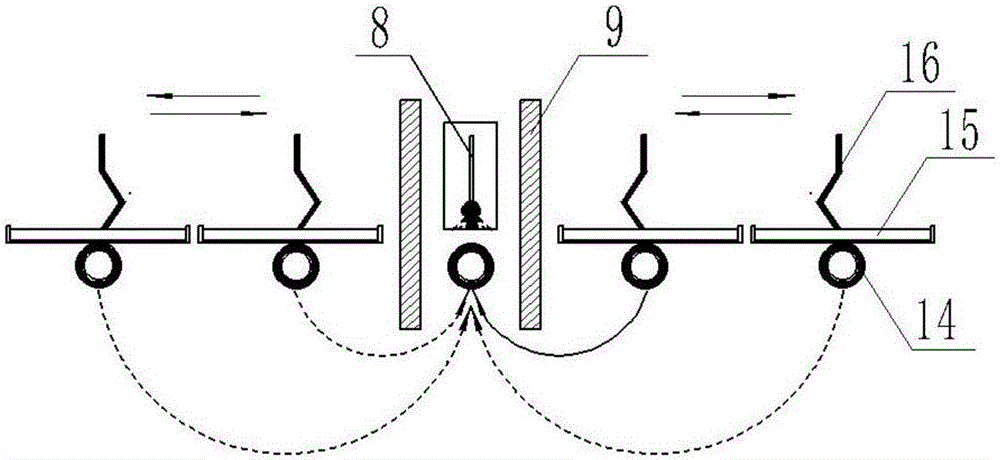

[0041] refer to Figure 4 , multi-color screen printing of elliptical bottles: the elliptical bottle 14 is placed on the feeding conveyor belt, and the feeding conveyor belt transports the elliptical bottle 14 to the bottle clamping position of the feeding industrial robot 5, and the industrial robot 5 clamps the elliptical bottle 14 Index (rotate 90 degrees clockwise), and then transfer to the product surface varnish dust removal treatment station 1401, the surface treatment system starts, and the outer surface treatment is performed on the printed product, and then the industrial robot 5 clamps the oval bottle product 14 and transfers it to the product No. The first screen printing position 1402, the product printing lifting table 12 moves upward in the direction of action of the first servo motor 10 through the first ball screw 11, so that the outer surface of the oval bottle is close to the printing screen of the first screen printing position 1402 On the bottom surface of...

Embodiment example 2

[0043] refer to Figure 5 , hexahedral square bottle multi-color screen printing: the hexahedral square bottle 14 is placed on the feeding conveyor belt, and the feeding conveyor belt transports the hexahedral square bottle 14 to the bottle clamping position of the feeding industrial robot 5, and the industrial robot 5 clamps it The hexahedral square bottle product is rotated 14 times (rotating 90 degrees clockwise), and then sent to the product surface varnish dust removal treatment position 1401, the surface treatment system is activated, and the outer surface of the hexahedral square bottle is treated, and then the hexahedral square bottle is clamped by the industrial robot 5 14 shift to the first screen printing position 1402 of the product, and the product printing lifting table 12 moves upward in the direction of action of the first servo motor 10 through the first ball screw 11, so that the outer surface of the hexahedral square bottle is attached to the first silk scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com