Chip type exploding foil component and production method for same

A production method and explosion foil technology, which are applied in the field of impact sheet detonators, can solve the problems of restricting the popularization and application of impact sheet detonators, unable to meet mass demand, low production efficiency, etc., and achieve good product quality consistency, simple structure, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

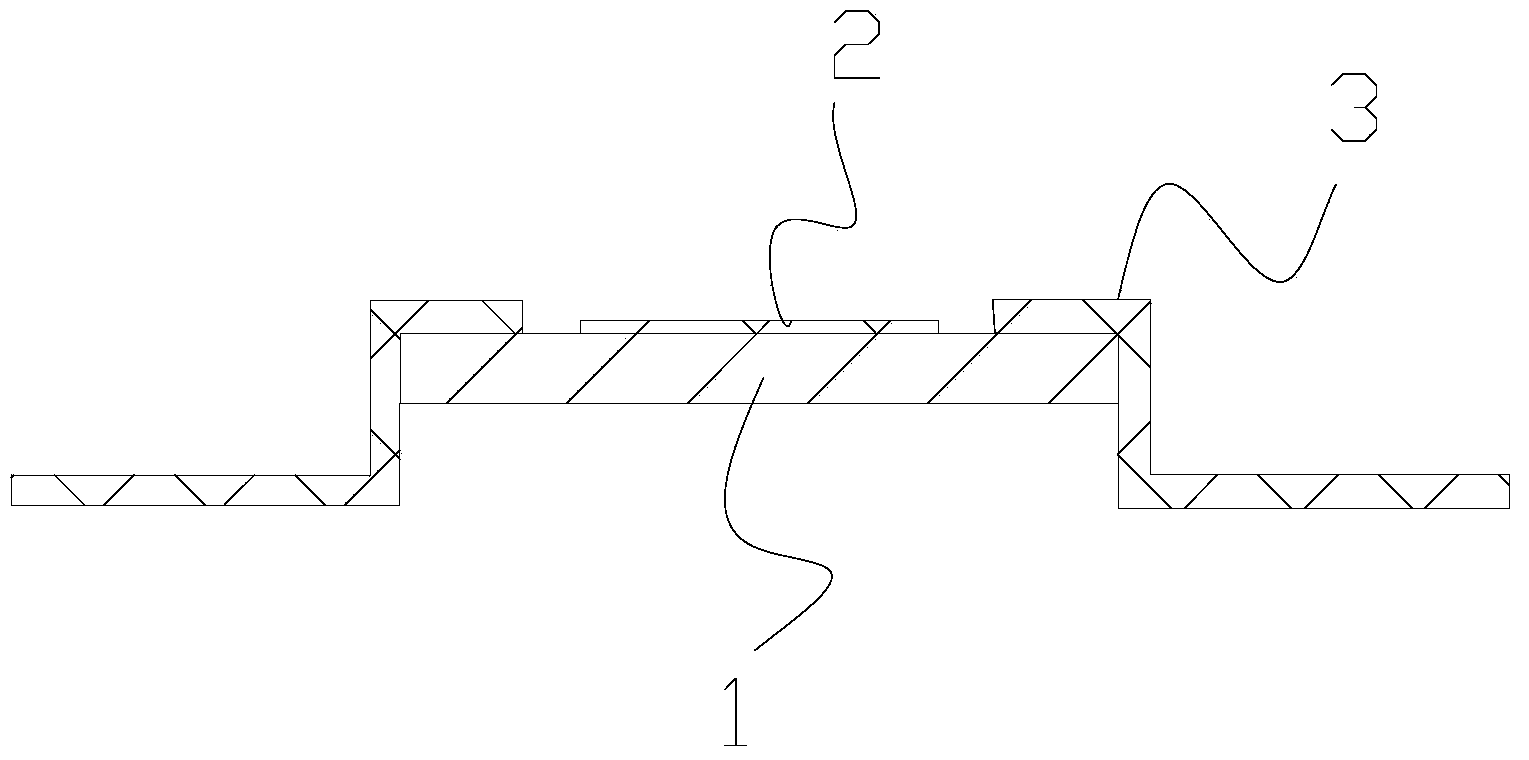

[0018] Such as figure 1 as shown, figure 1 A schematic structural diagram of an embodiment of the present invention is shown. In this embodiment, the chip-type explosive foil assembly includes the explosive foil 1, the flyer 2 and the electrode 3, and the flyer is bonded to the explosive foil; the chip-based design idea is adopted, the explosive foil is a rectangle, and the explosive foil array is placed on the base. The sheet is formed, and the electrode is formed by stamping. The electrode is copper foil, which is welded on the explosion foil.

[0019] According to another embodiment of the present invention, a method for producing a chip-type explosive foil assembly is provided. The specific production steps are: the outer shape of the explosive foil is rectangular, and a copper film or copper film is evaporated or magnetron sputtered on a larger ceramic substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com