Screen printing machine and printing method thereof

A screen printing machine, screen printing technology, applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve problems such as bridging defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

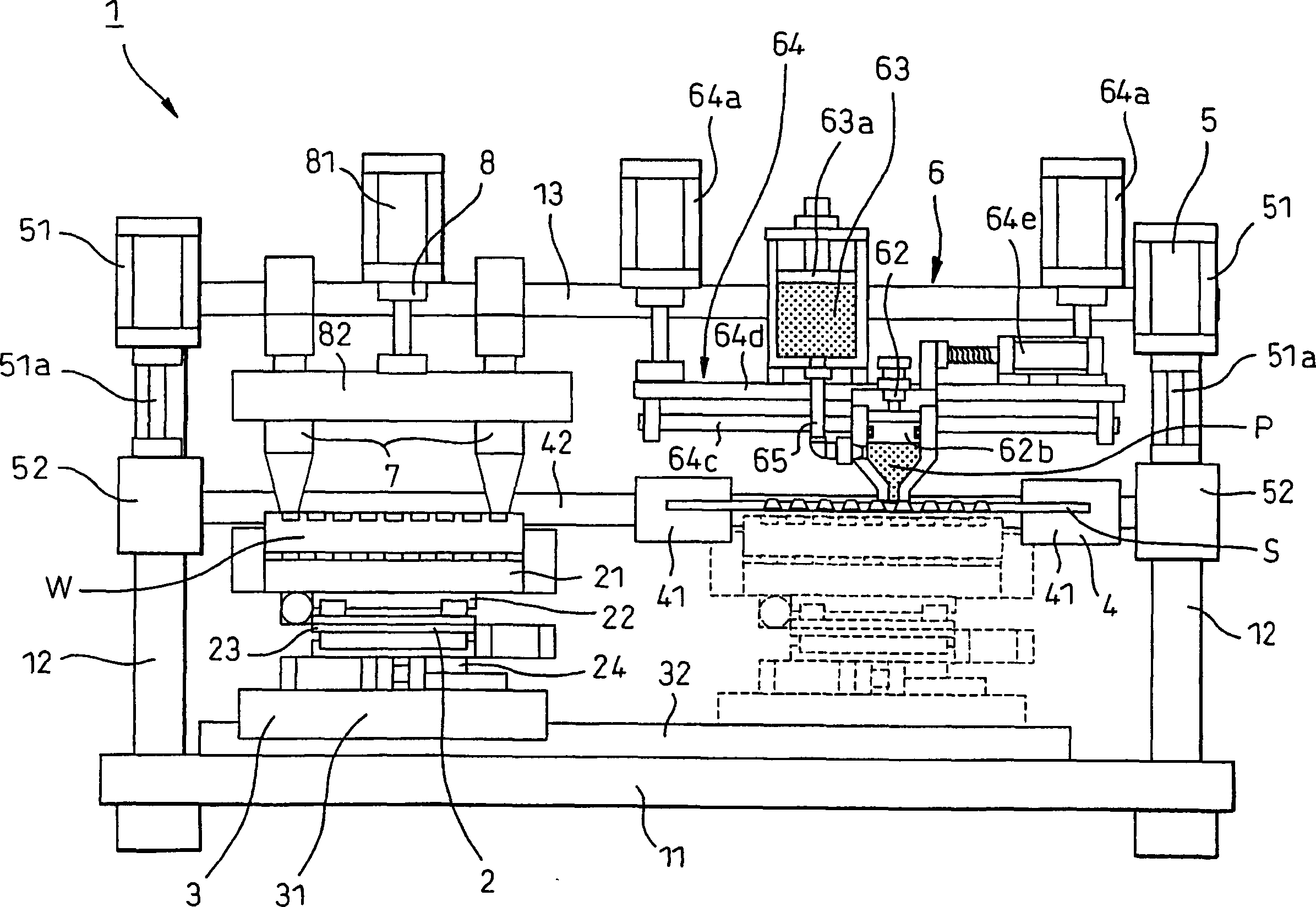

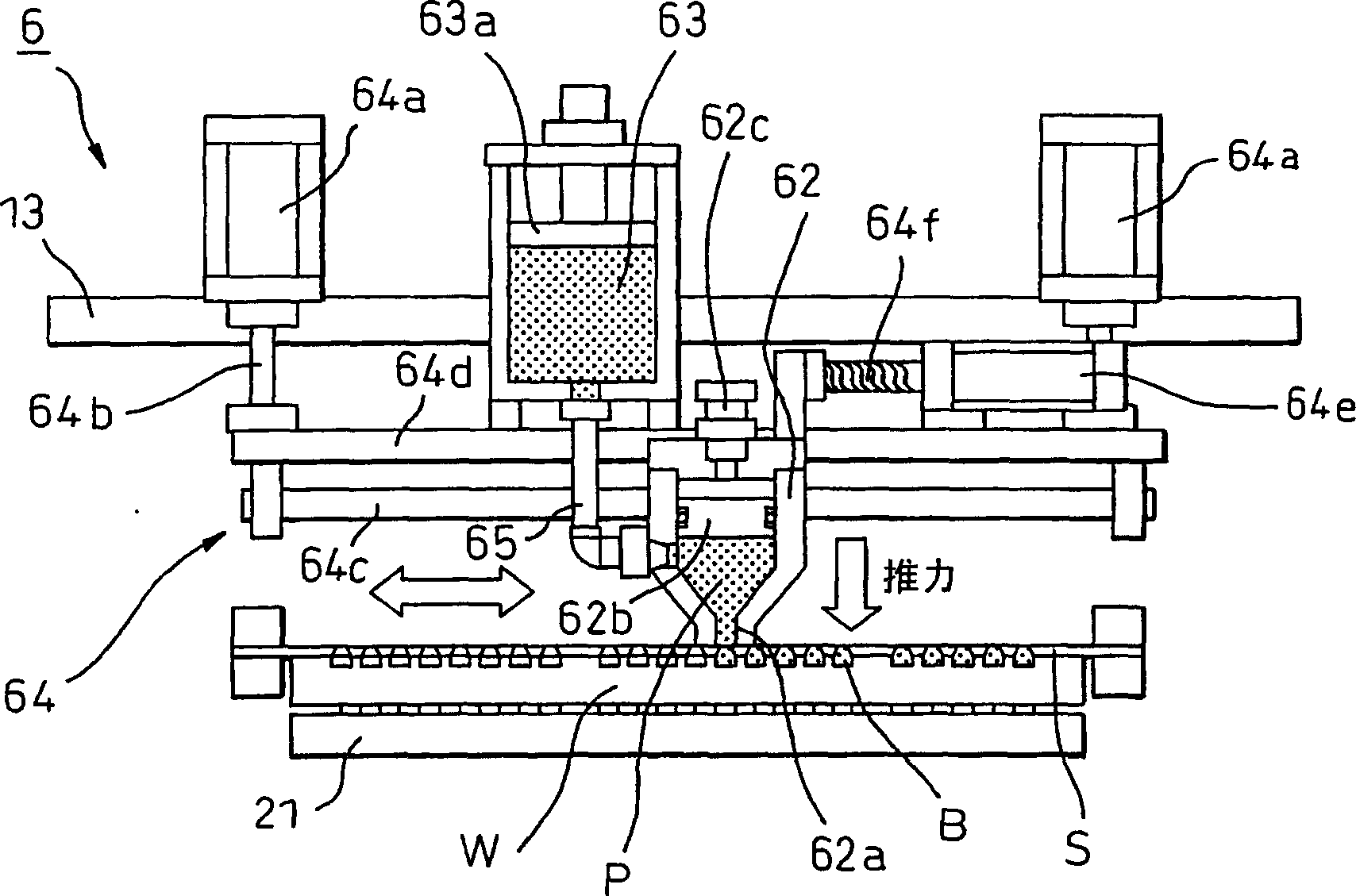

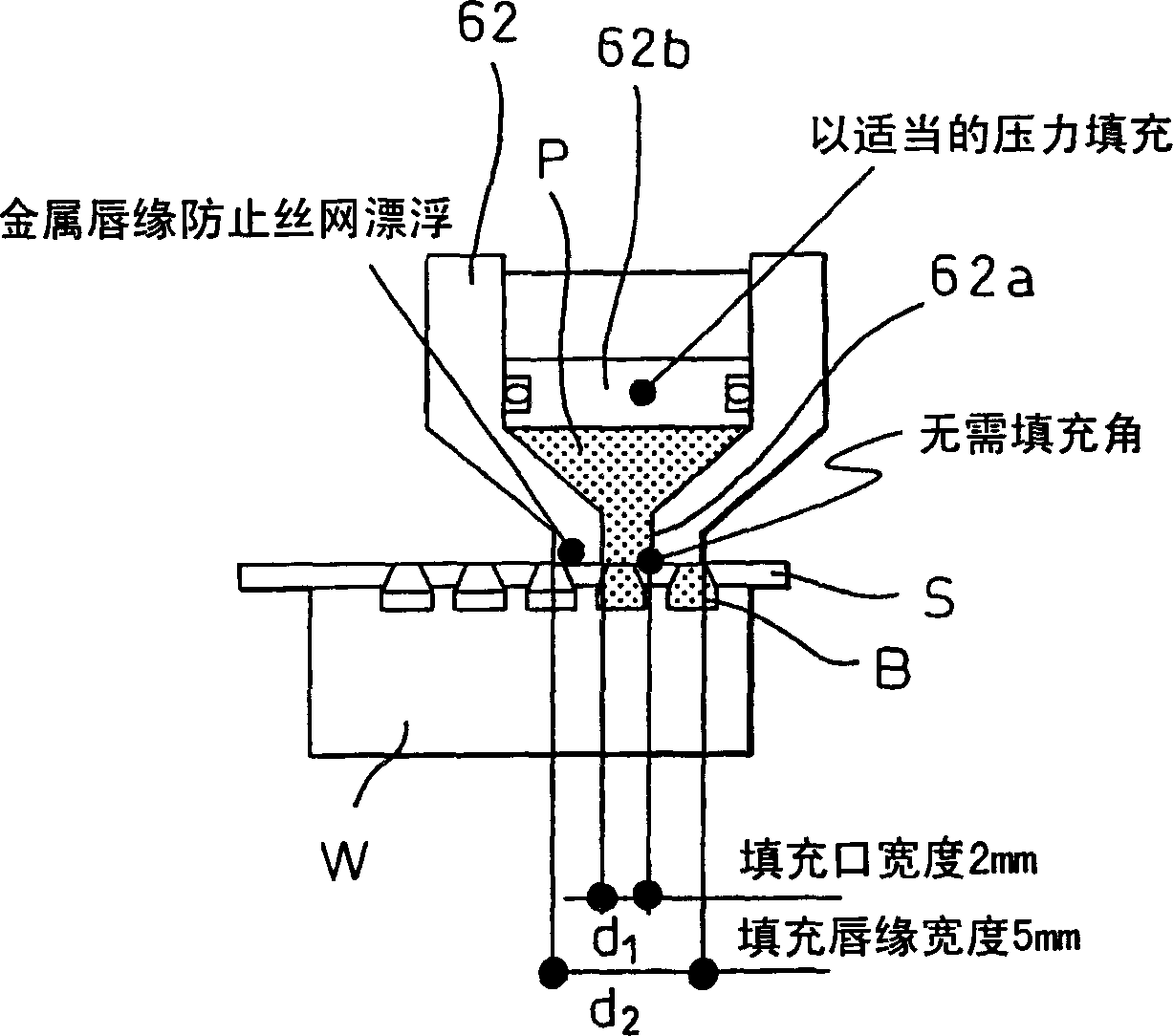

[0025] A screen printing machine and a printing method thereof according to embodiments of the present invention will be explained below with reference to the accompanying drawings. figure 1 is a view showing the overall configuration of the screen printing machine according to this embodiment of the present invention, figure 2 is as figure 1 An enlarged view of the main part of the printing mechanism. The screen printing machine 1 basically includes a workpiece alignment mechanism 2 for positioning a workpiece W as a substrate in X, Y, and θ directions, and a mechanism for linearly moving the workpiece W between a workpiece alignment position and a printing position. The workpiece moving mechanism 3, the screen moving mechanism for linearly moving the screen S (screen cover) between the workpiece alignment position and the printing position 4, the screen lifting mechanism for moving the screen S up and down 5, with A printing mechanism 6 for printing solder paste P onto ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com