Direct drive screen CNC scraper device

A scraper device, direct-drive technology, applied in the field of direct-drive screen CNC scraper device, can solve the problems of mechanical performance discount, complex mechanical structure, difficulty in ensuring accuracy, etc., and achieve easy operation control, precise motion control, and precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments.

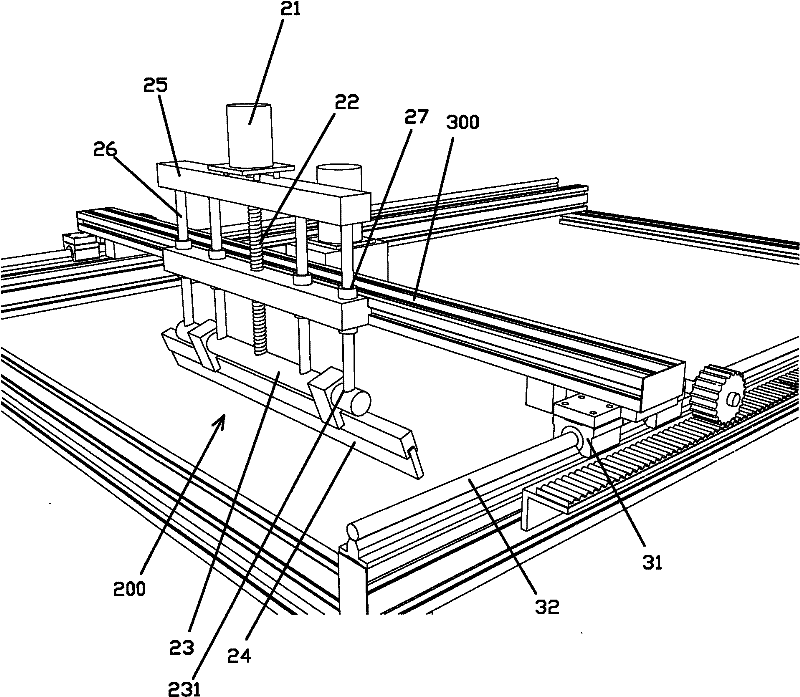

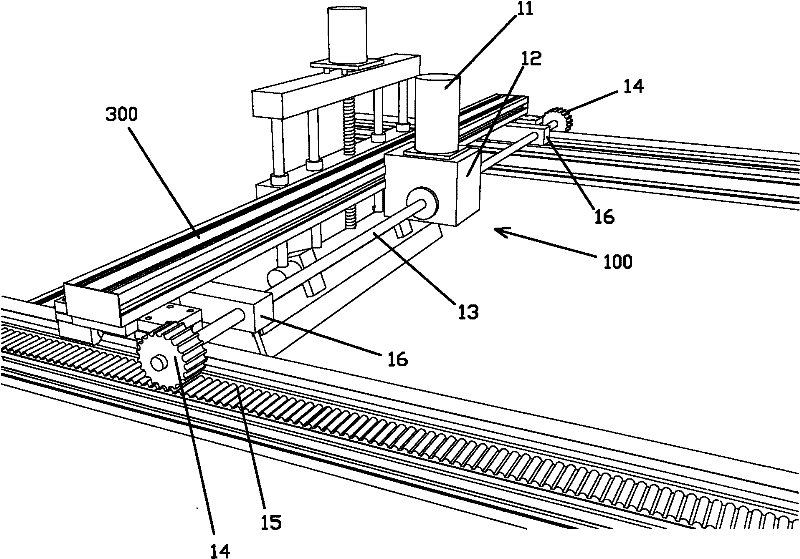

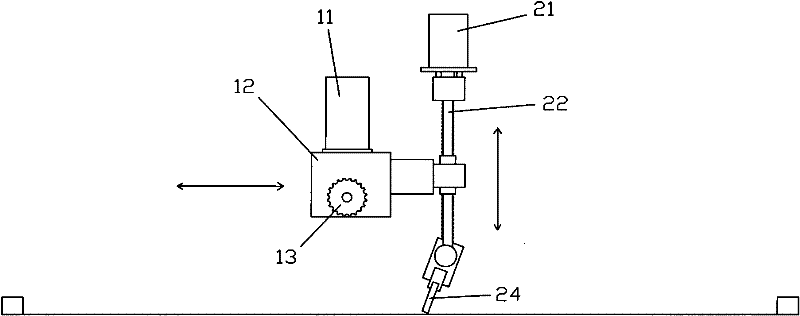

[0022] Reference figure 1 with figure 2 , The direct-drive screen numerically controlled scraper device of the present invention includes a printing stroke unit 100, a scraper stroke unit 200 and a connector 300 connecting the two together.

[0023] Reference figure 1 The scraper stroke unit 200 includes a scraper servo motor 21. The output end of the scraper servo motor 21 is connected with a ball screw 22. The end of the ball screw 22 is fixedly connected to the scraper 24 by a scraper connector 23; the scraper stroke unit 200 also includes The support plate 25 carrying the scraper servo motor 21 is fixedly connected to the support plate 25 with a linear circular rail assembly 26, the linear circular rail assembly 26 passes through the linear bearing assembly 27 and is fixedly connected to the scraper connector 23, and the linear bearing assembly 27 is fixed to the connector 300 On; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com