Screen printing machine

A technology for screen printing machines and printing devices, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of reducing printing work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention is further described below in conjunction with specific embodiment and accompanying drawing, but it is not limited thereto:

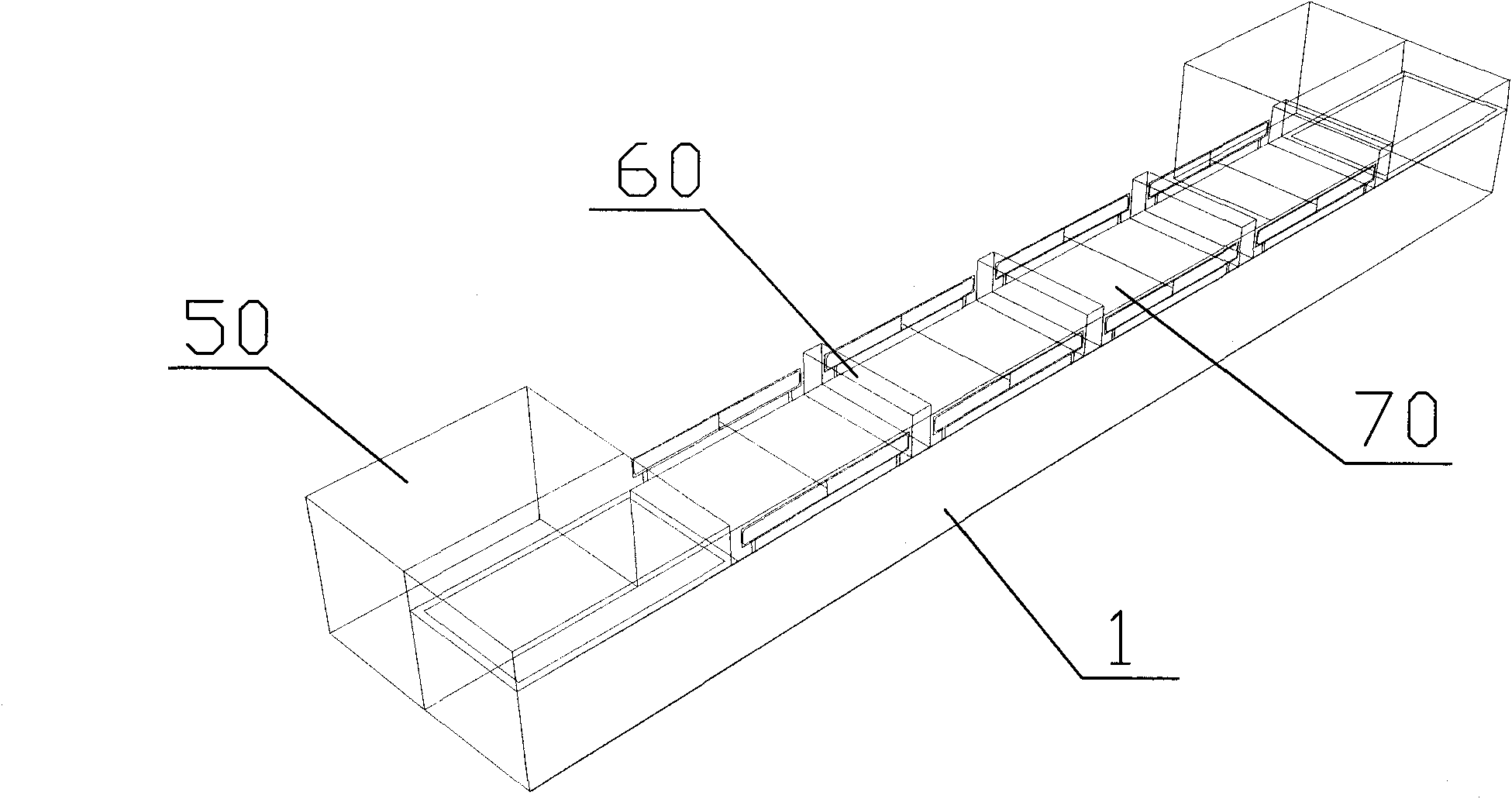

[0033] This screen printing machine provided by the invention, such as figure 1 As shown, it mainly includes:

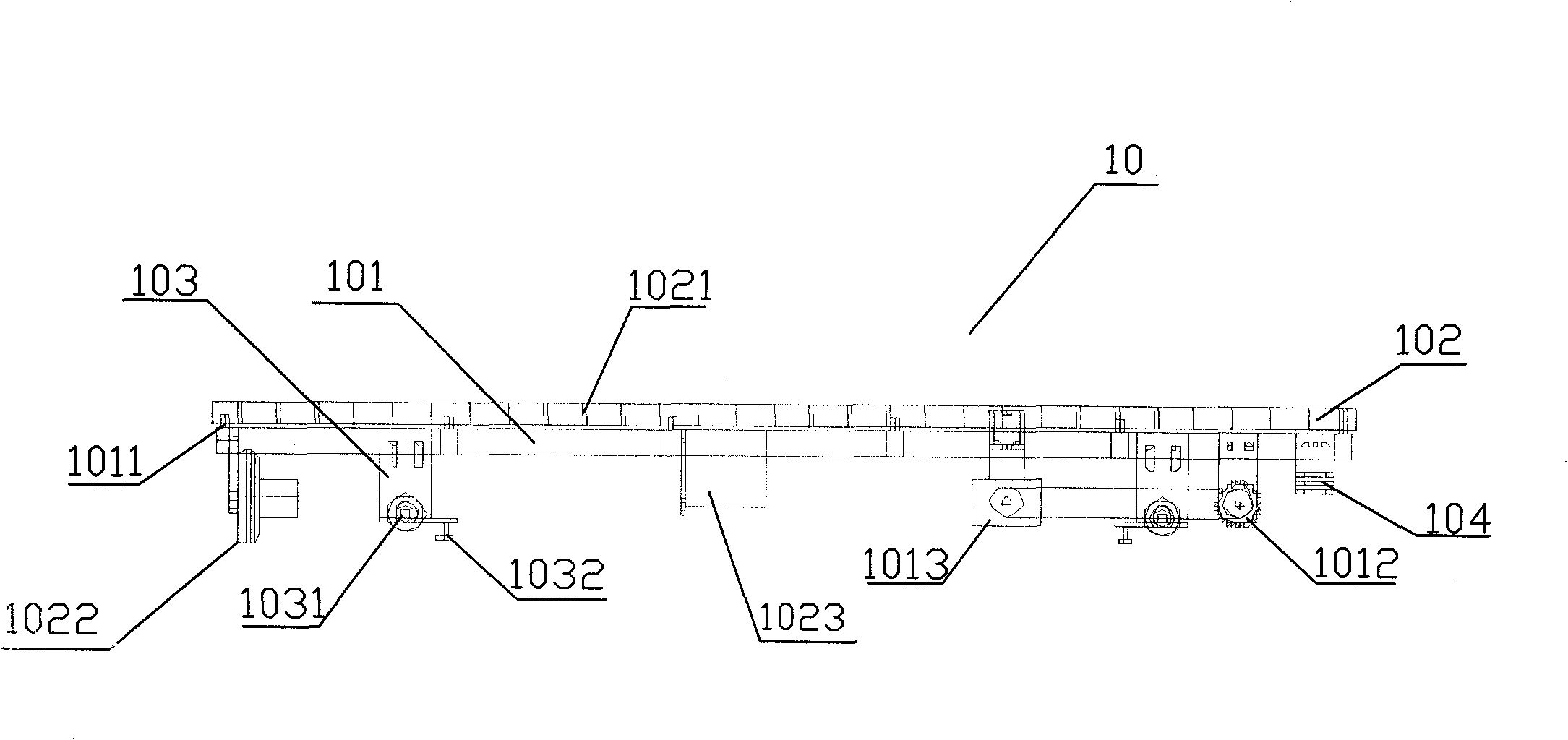

[0034] Rack 1;

[0035] a plurality of automatic operation suction platforms arranged on the frame 1;

[0036] A plurality of printing devices 70 installed on the frame;

[0037] An ink curing and drying device 60 installed on the frame and behind the printing device;

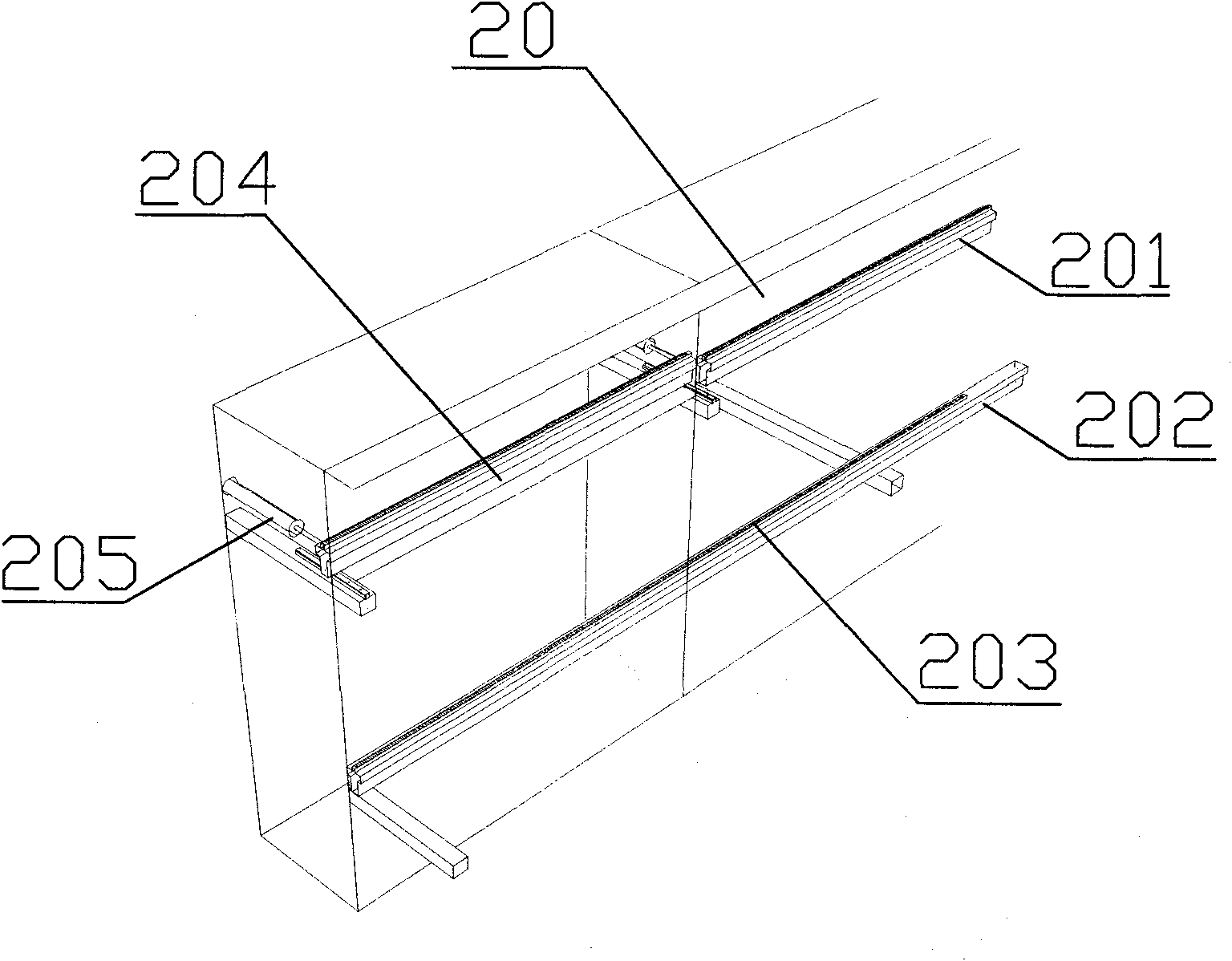

[0038] A screen carrying device installed on the frame and relative to the position of the printing device;

[0039] Slewing device installed on the frame;

[0040] a lifting device mounted on the frame;

[0041] An automatic feeding and retrieving device 50 installed at the front and back of the frame;

[0042] Power transmission devices installed on racks and automatic operation platforms;

[0043] An automatic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com