Silkscreen machine with automatic positioning function

An automatic positioning and screen machine technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of low automation, low printing efficiency, complex structure, etc., to improve printing accuracy and speed , precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

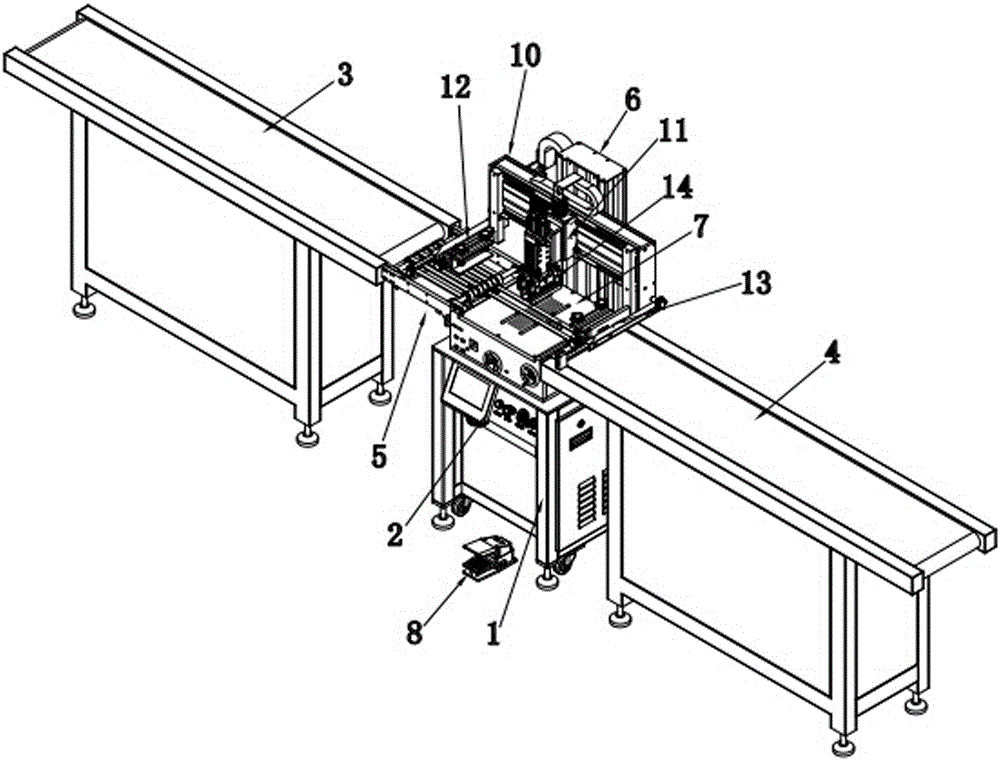

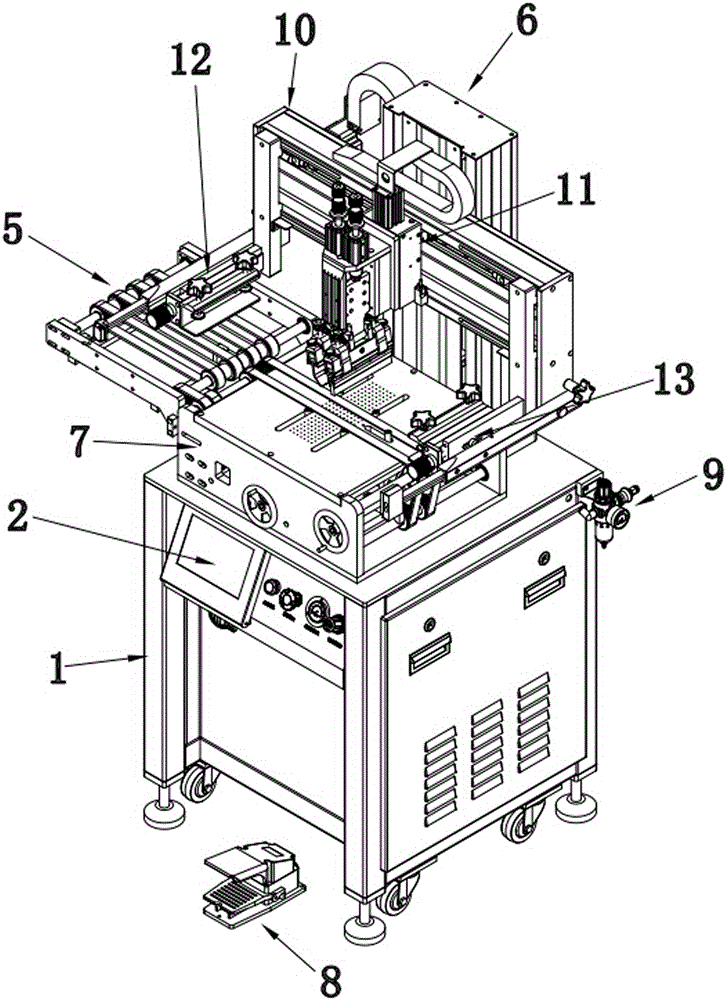

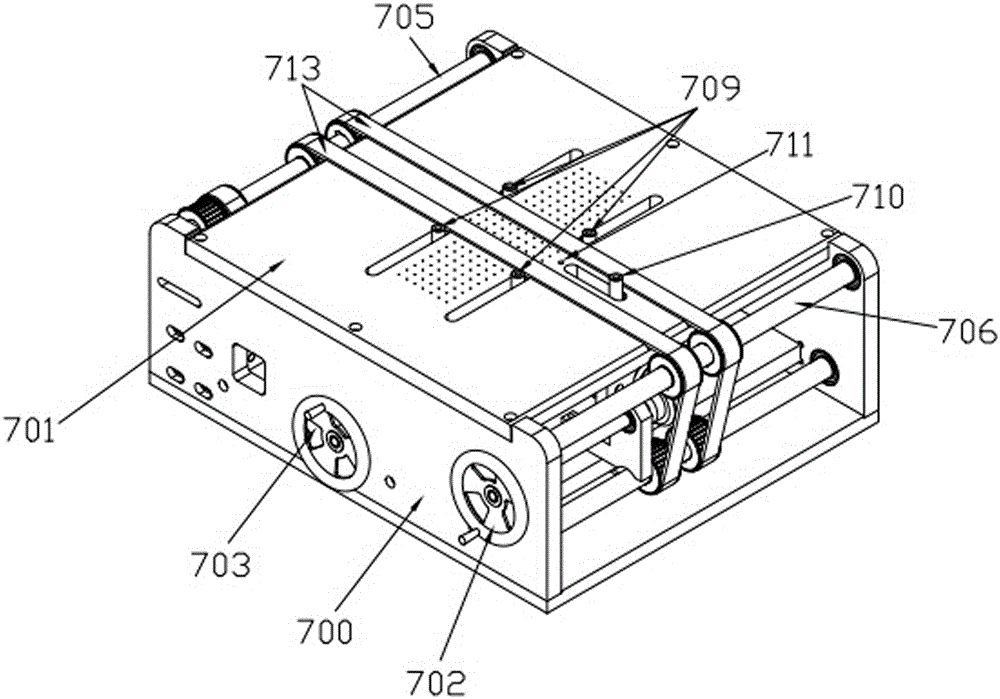

[0037] In this embodiment, refer to Figure 1 to Figure 11 , the automatic positioning screen machine in this program includes a frame 1 of the screen printing machine and an interface operating system 2 arranged on the frame 1. The frame 1 of this embodiment is formed by splicing or welding steel structures and spraying , the frame 1 has a detachable upper cover, a base plate, a front baffle, a rear baffle and left and right side panels between the front baffle and the rear baffle, the upper cover, the base plate, the front baffle, The rear baffle and the left and right side panels form an inner cavity for installing the interface operating system 2, the top surface of the frame 1 is an installation platform, and the left and right sides of the frame 1 are respectively provided with at least one set of Material conveyor belt 3 and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com