Display glass printing technology and refrigerator door shaping method using finished products formed thereby

A technology of colored crystal glass and process, applied in the directions of printing, application, printing device, etc., can solve the problems of low cost, limited coverage area of colored crystal glass, inability to realize the design of the door frame of the refrigerator, etc., to achieve frameless design, area maximized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

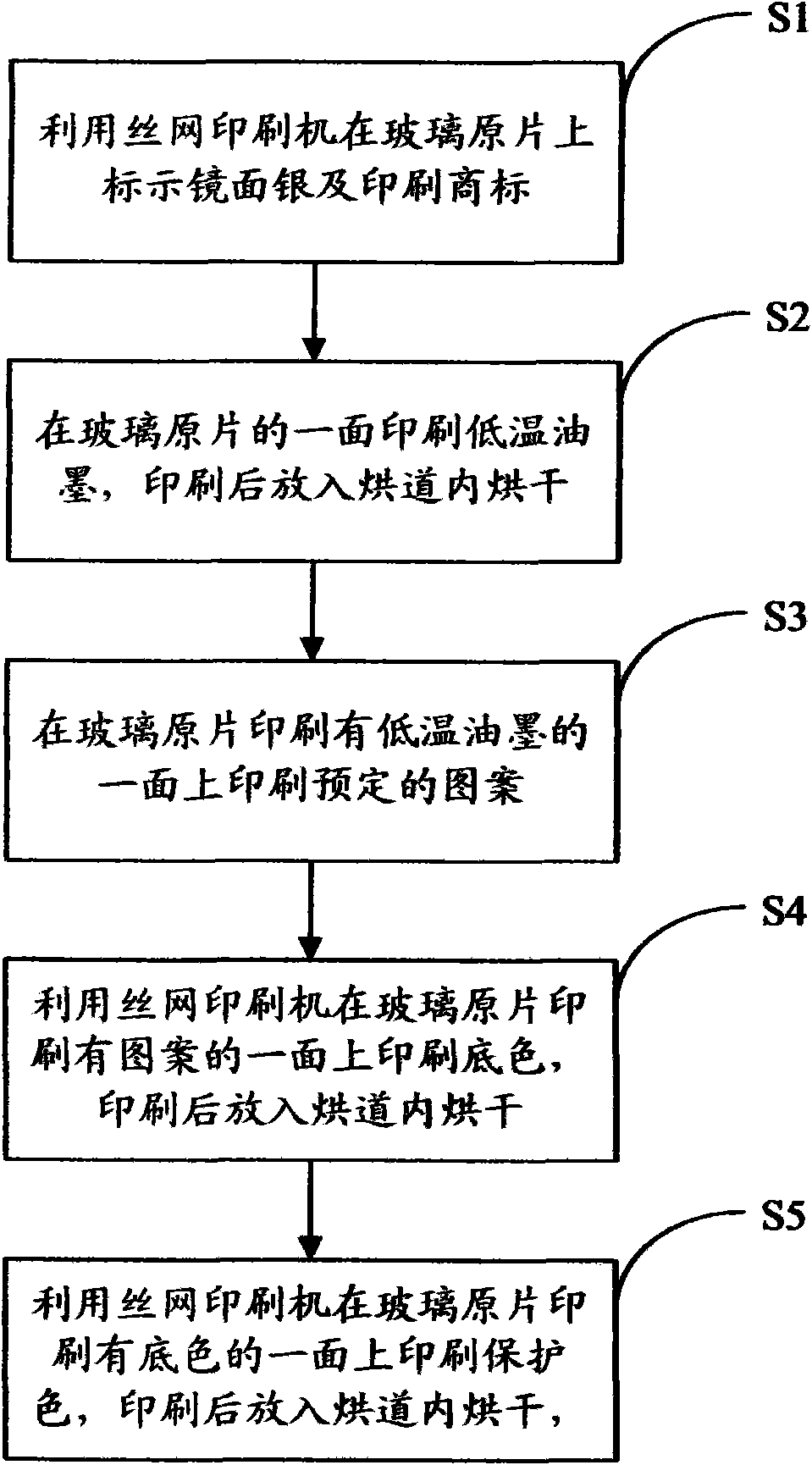

[0023] figure 1 It is the flow chart of the embodiment of the color crystal glass printing process of the present invention. As shown in the figure, the color crystal glass printing process of the present embodiment includes the following processes:

[0024] S1. Use a screen printing machine to mark mirror silver and printed trademarks on the original glass sheet;

[0025] Wherein the mirror silver and the trademark are located on the side to be printed with low-temperature ink; and this step does not need baking.

[0026] S2. Print low-temperature ink on one side of the original glass sheet, and put it into the drying tunnel to dry after printing;

[0027] Wherein the baking temperature is 170° C. to 200° C., and the baking time is 12 minutes to 18 minutes.

[0028] S3. Print a predetermined pattern on the side of the original glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com