Device and method for measuring the screen tension of the screen fabric in a silk screen frame

A screen and screen frame technology, applied in the field of screen printing machines, can solve the problems of changing the contact area, increasing the contact area, and not providing a method for identifying the crack of the screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

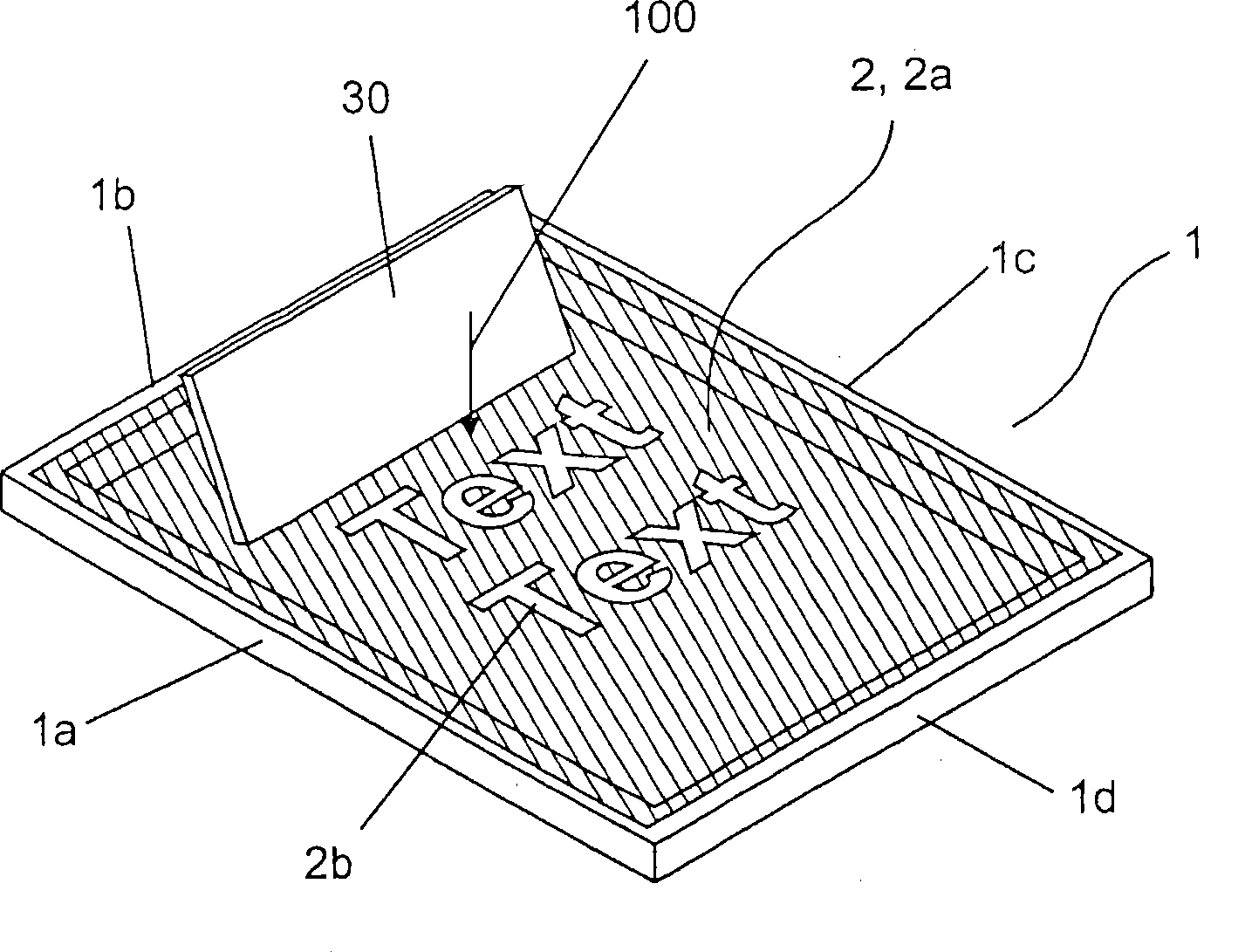

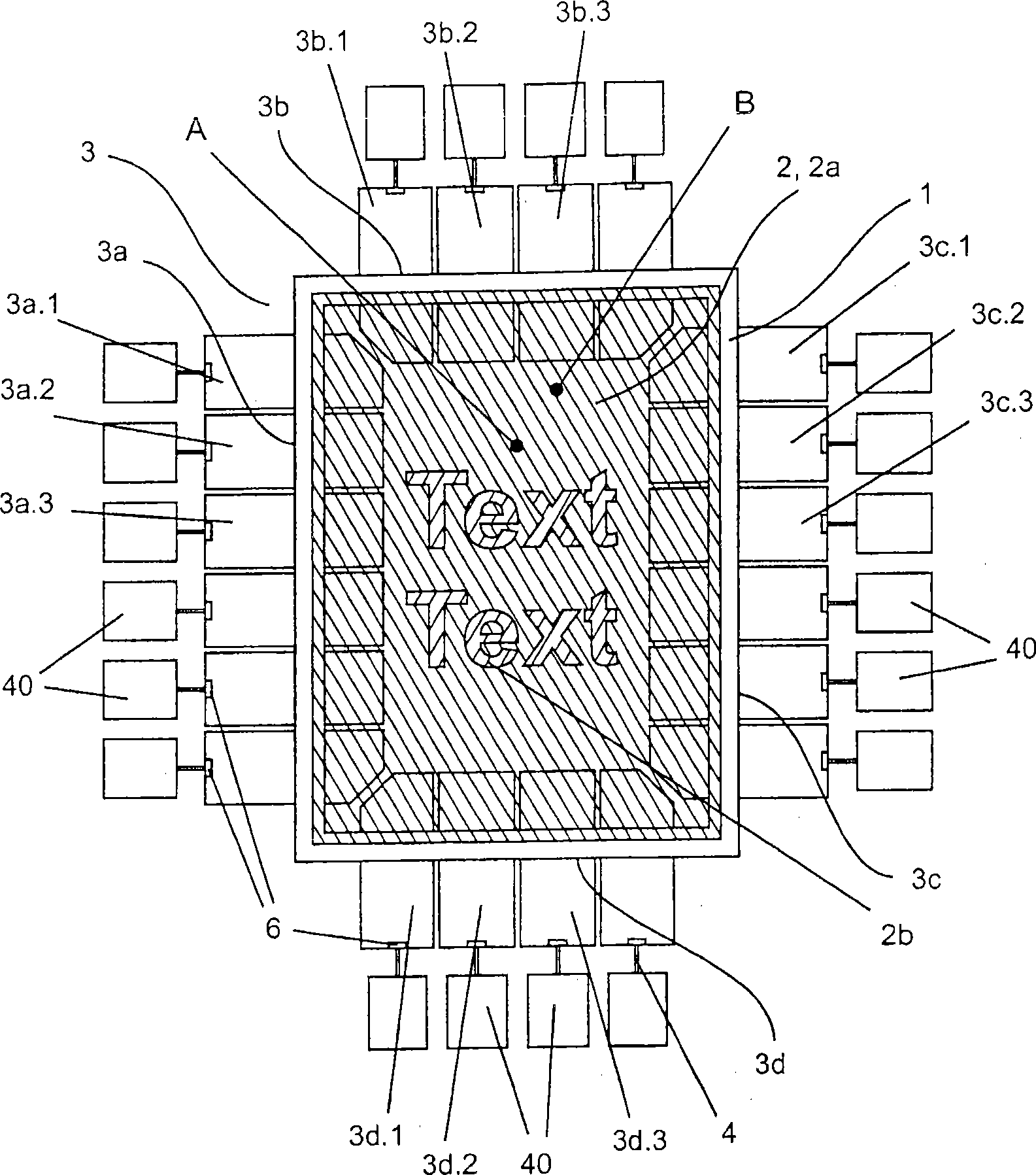

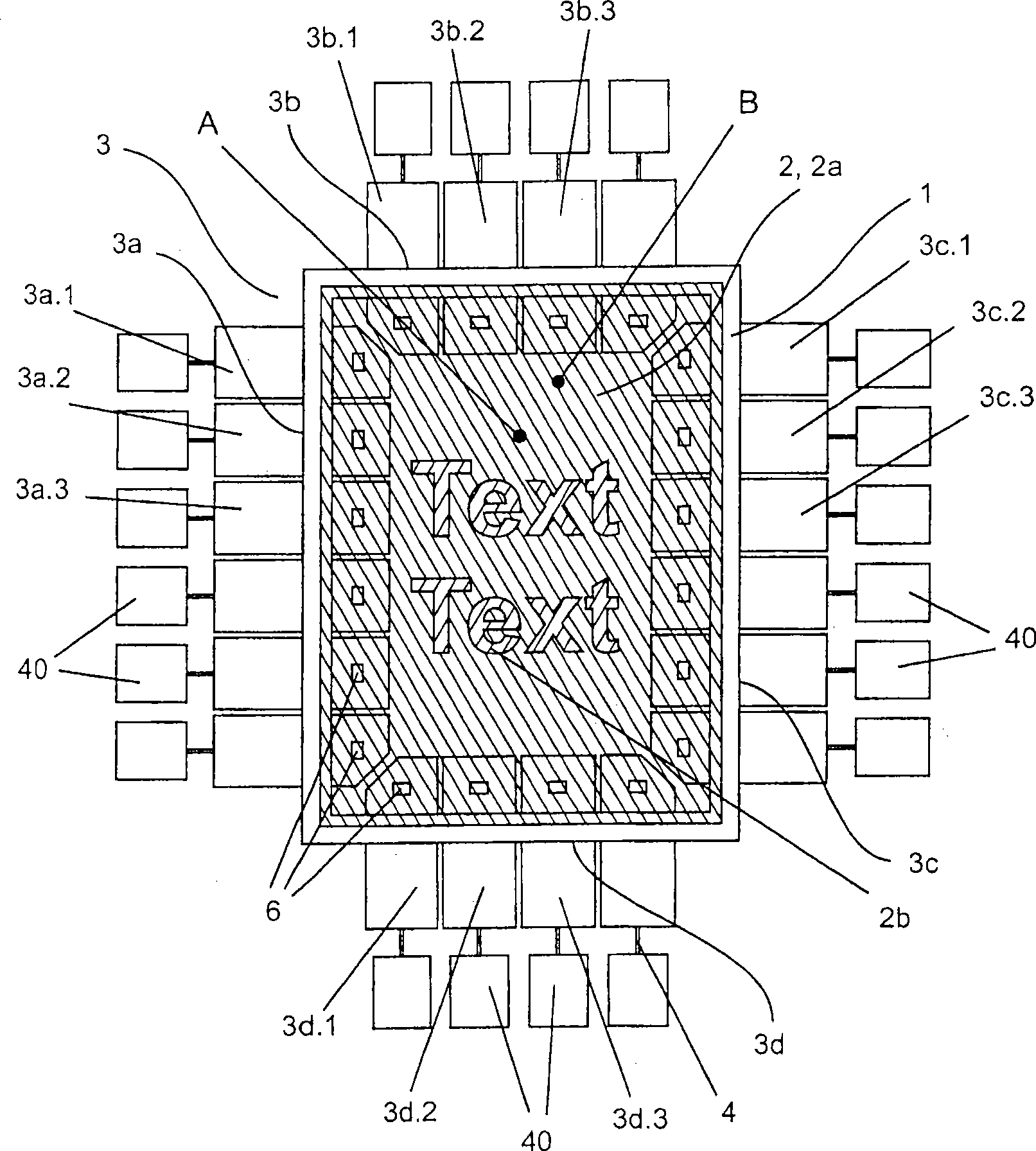

[0034] attached figure 1 Shown is a schematic diagram of a silk screen frame with a pattern commonly used in industrial screen printing devices. The screen fabric 2 that is provided with coating is stretched so tightly on a screen printing screen frame 1 that is, for example, rectangular and includes 4 side screen frame members 1a, 1b, 1c, 1d, so that the screen fabric 2 has a certain, The base tension set in fabrication.

[0035] Usually, the screen fabric 2 and the screen frame are bonded together so as to ensure that the screen fabric 2 is well bonded to the screen frame 1 on the one hand, and on the other hand to form an impermeable gap between the screen frame 1 and the screen fabric 2. Ink connection. It can also be fixed in other ways, such as clamping the wire mesh fabric between the upper and lower screen frame members.

[0036] The coating 2a of the screen fabric 2 is removed for printing at the locations 2b, so that the ink penetration between the meshes of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com