Conveying device for material carrying

A technology for conveying devices and materials, applied in the field of transportation, can solve problems such as poor applicability, inability to meet production needs, waste of resources, etc., and achieve the effects of convenient operation, multi-layer utilization, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

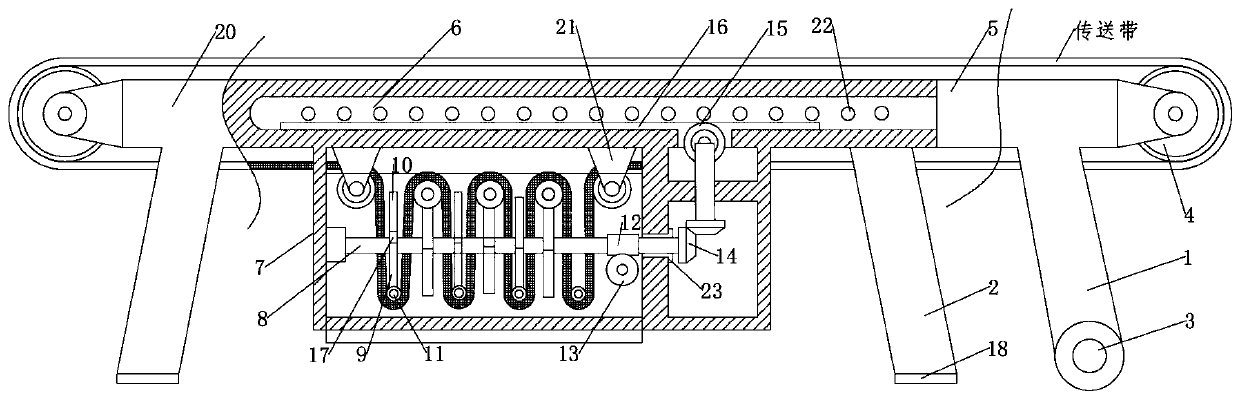

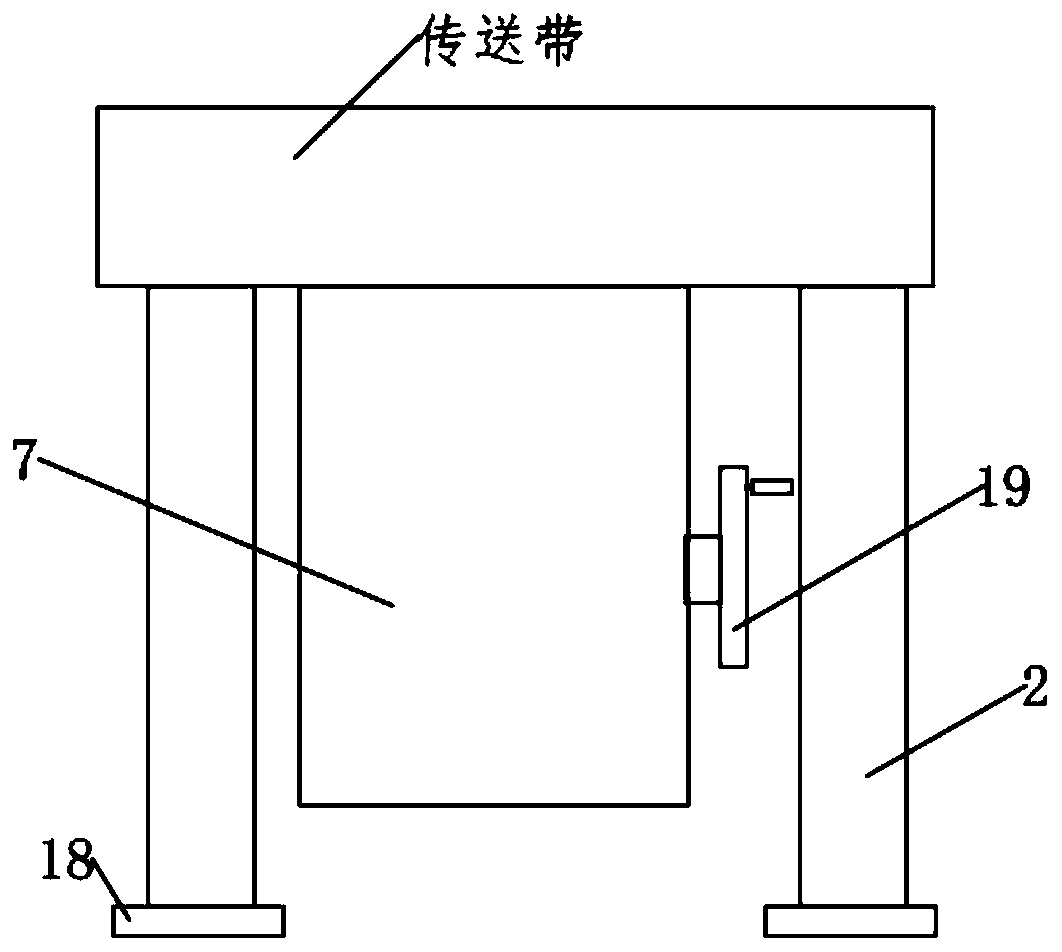

[0019] see Figure 1-2 , a conveying device for material handling, comprising a fixed bracket 20 and a fixed foot support 2, a mobile bracket 5 is slidably installed on the fixed bracket 20 through a sliding rod 6, and a rotating bracket 5 is installed on one end of the fixed bracket 20 and the mobile bracket 5 to rotate Wheel 4, and then the conveyor belt expansion account is installed on the rotating wheel 4, the bottom of the fixed bracket 2 is equipped with an adjustment box 7, and the conveyor belt passes through the adjustment box 7; the fixed foot support 2 Fixedly installed on the fixed bracket 20; the mobile bracket 5 is fixedly installed with a mobile foot support 1, and the mobile foot support 1 is rotatably equipped with a roller 3, and then the device pulls the mobile during actual use. The bracket 5 makes the sliding rod 6 slide along the fixed bracket 20, thereby adjusting the length of the conveyor belt; the adjustment box 7 is used to adjust the length and the...

Embodiment 2

[0027] In order to further improve the rotation effect of the rotating shaft 8 of the device, this embodiment makes the following improvements on the basis of the first embodiment. The improvement is that a bushing 23 is installed on the inner wall of the rotating shaft 8 and the adjustment box 7 for rotation. , the friction force between the rotating shaft 8 and the adjustment box 7 is further reduced by the bushing 23; and the rotation effect of the rotating shaft 8 is further improved.

[0028] The working principle of this embodiment: a bushing 23 is arranged between the rotating shaft 8 and the adjusting box 7, and the rotating effect of the rotating shaft 8 is improved through the reduced frictional force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com