High-efficiency grain conveying system

A conveying system and grain technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of increasing belt running resistance, belt wear, inability to adjust the length of the conveyor, and affecting the working efficiency of the conveyor belt, etc., to achieve Improve work efficiency, simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

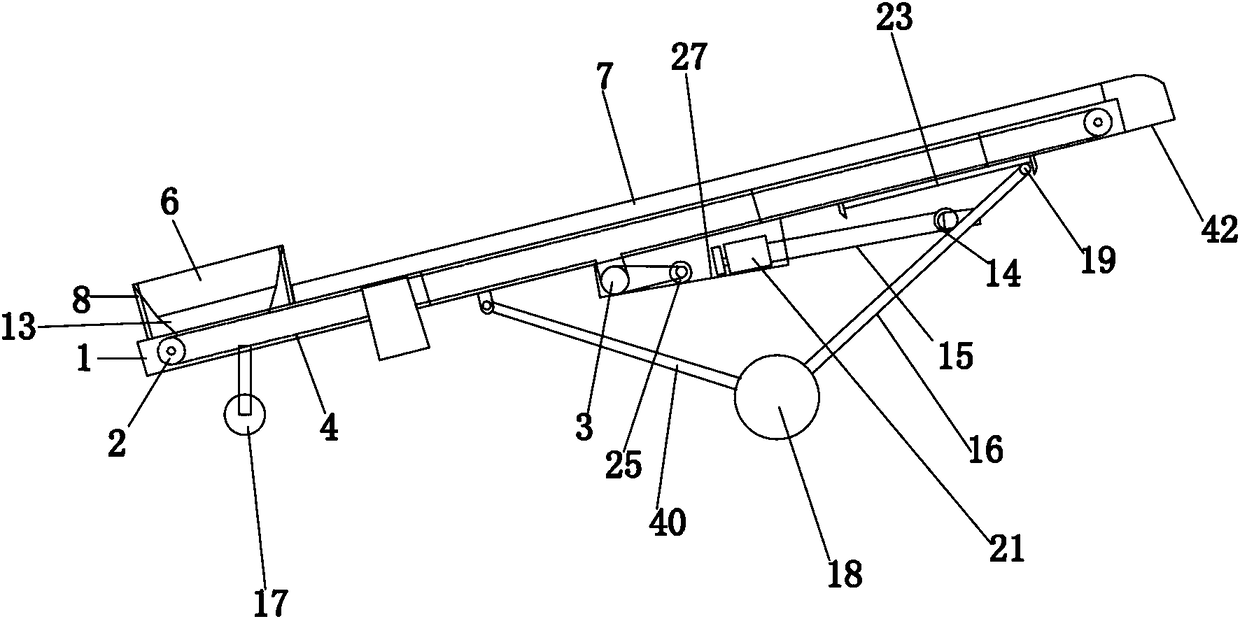

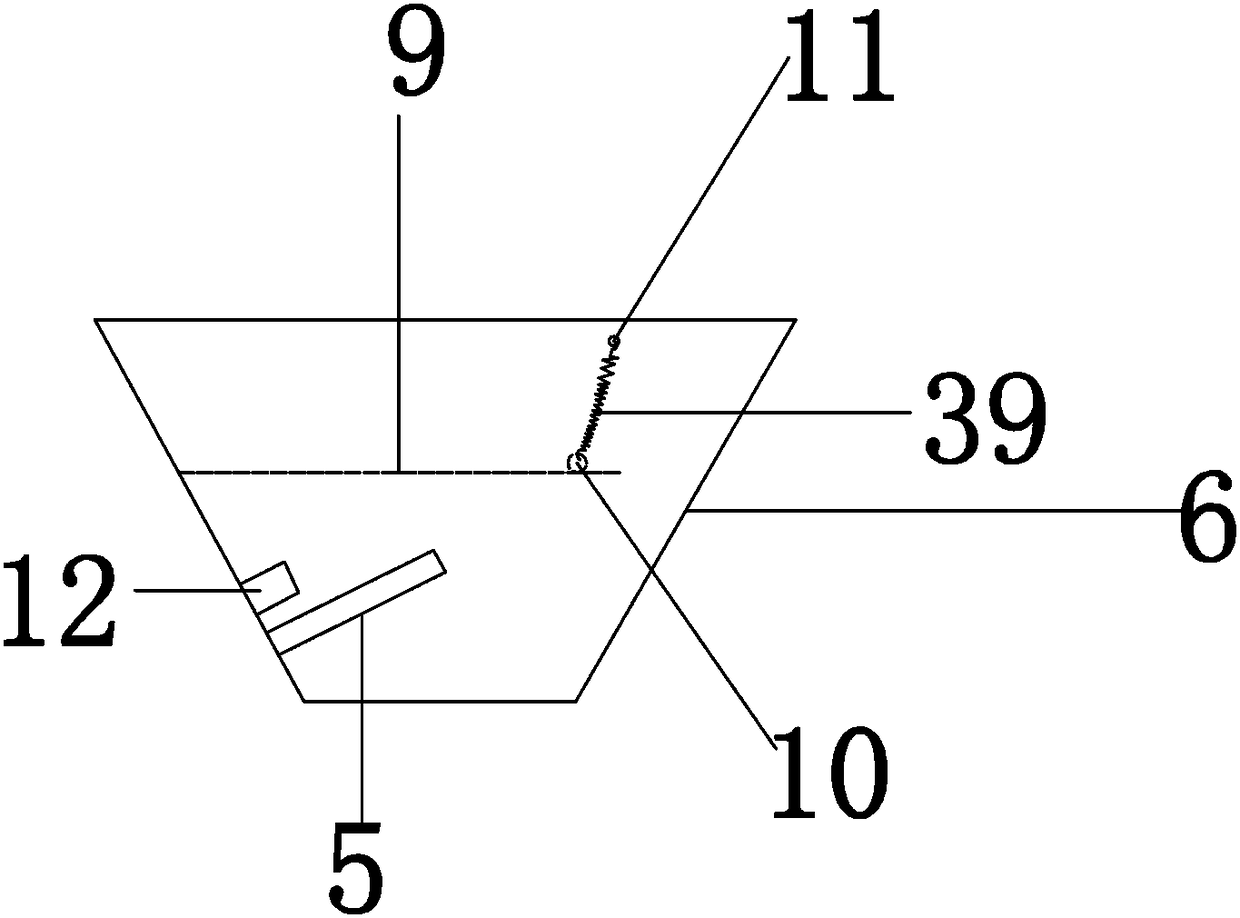

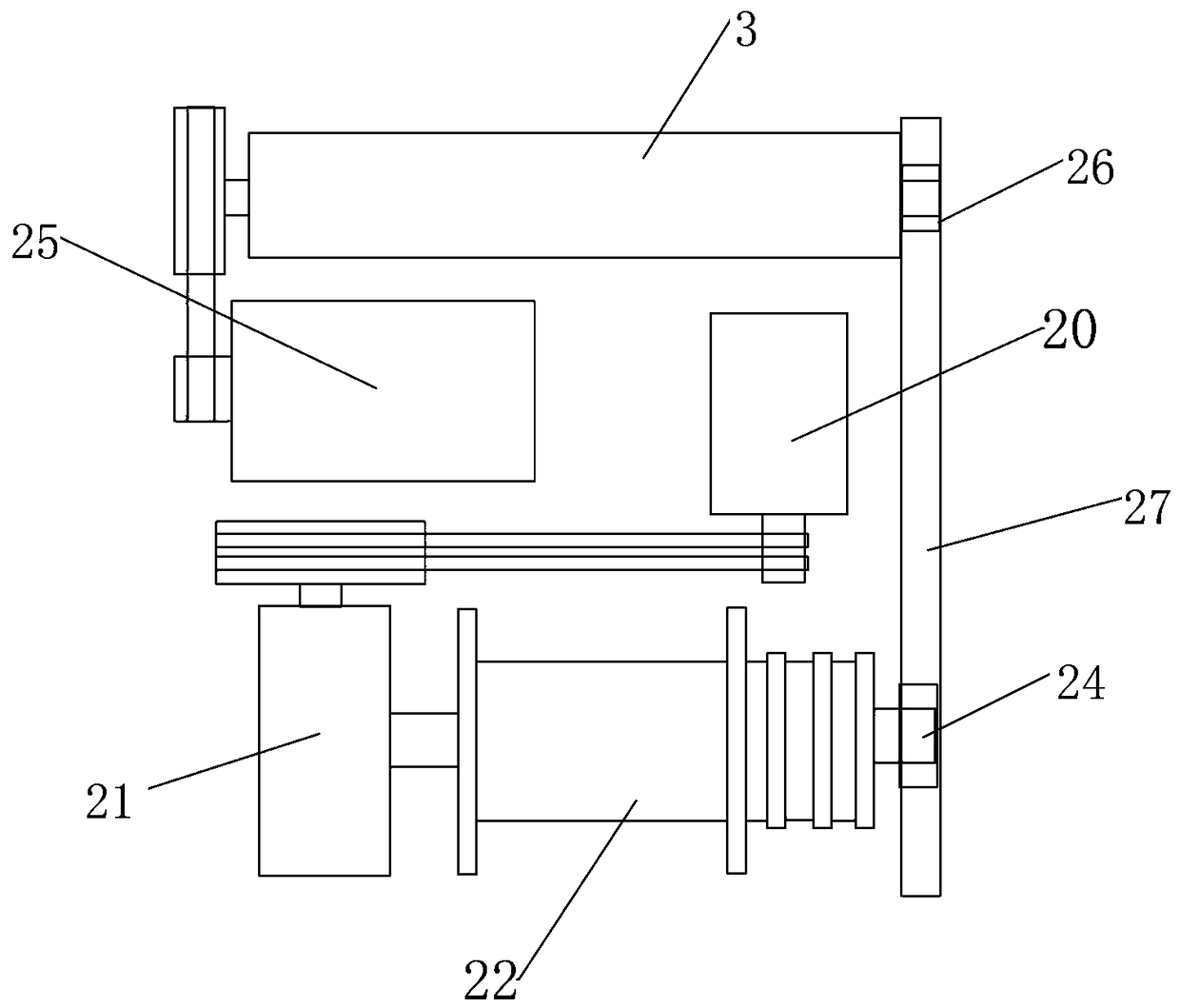

[0024] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a high-efficiency grain splicing and conveying system includes a frame, two driven rollers 2 connected to both sides of the frame, and a fixed bracket 27 arranged at the bottom of the frame , the driving roller 3 connected to the fixed bracket 27, the conveyor belt 4 connected to the outside of the driven roller 2 and the driving roller 3, the control cabinet arranged on the side of the frame, and the discharge device arranged on one side of the bottom of the frame Port 42, characterized in that: the frame is composed of a plurality of identical side plates 1 connected by bolts and the support rods 38 connected between the side plates 1, the side plates 1 are grooved structures, and the frame A sealing cover 7 is connected to the top surface of the sealing cover 7, and a feeding hopper 6 is arranged on one side of the sealing cover 7, and a feeding induction device is connected in the feeding hopper 6, and a driving wheel 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com