Roller device

A roller and adjusting device technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of not being able to adapt to the pulling requirements of fabrics of different thicknesses, the pulling requirements cannot be met, and the spacing cannot be automatically adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

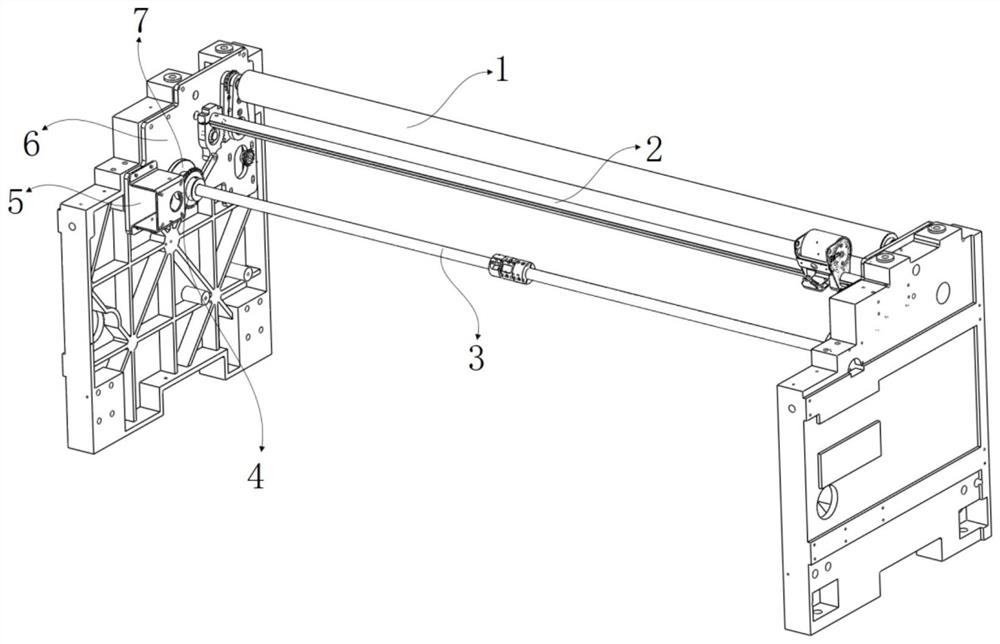

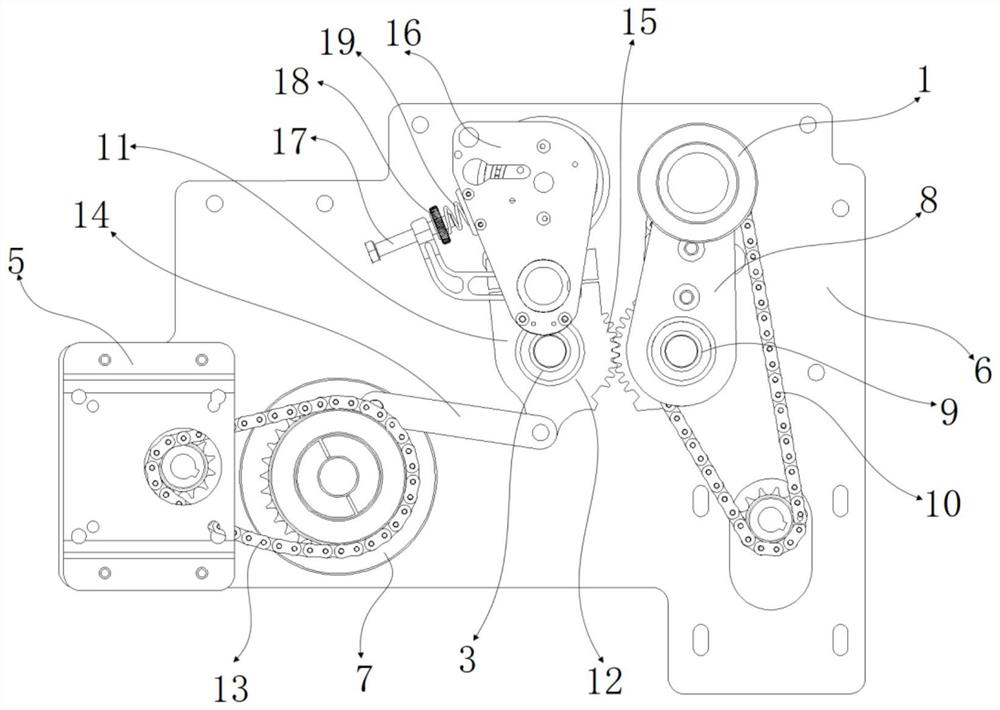

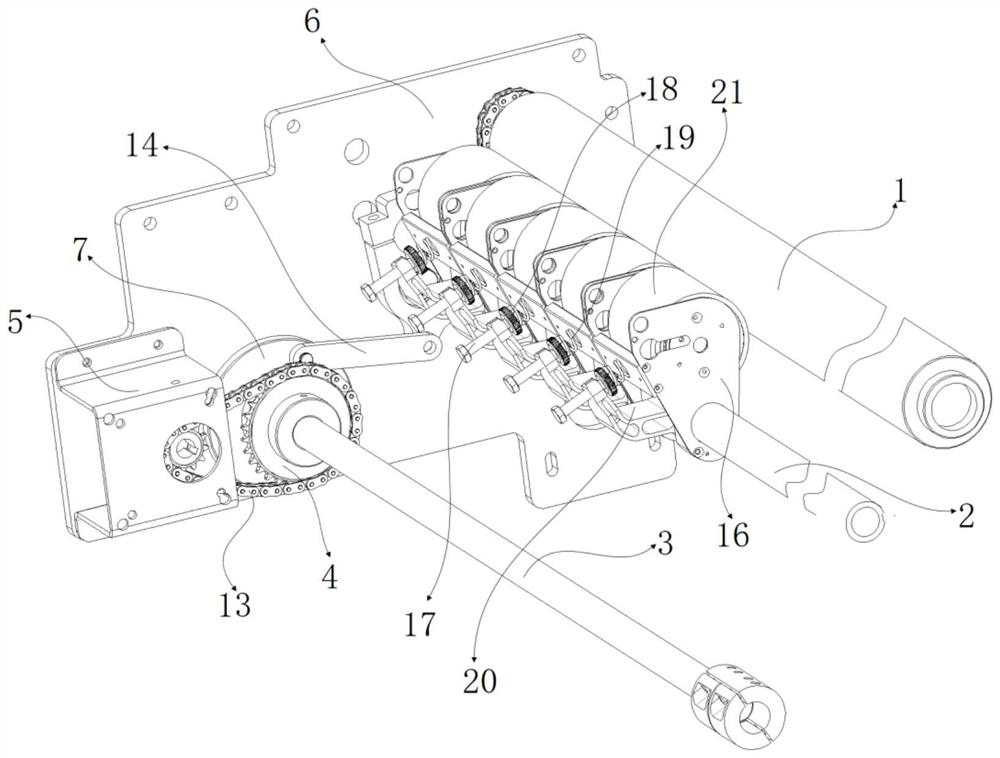

[0022] Such as Figure 1-9 As shown, the roller adjusting device comprises a first roller 1 and a second roller, and one end of the first roller 1 is installed on the first opening and closing seat 8 (as figure 2 As shown), the other end of the first roller 1 is installed on the second opening and closing seat. One end of the second roller is installed on the third opening and closing seat 11, and the other end of the second roller is installed on the fourth opening and closing seat. The first opening and closing seat 1, the second opening and closing seat, the third opening and closing seat 11, and the fourth opening and closing seat respectively pass through the first rotating shaft 9, the second rotating shaft, and the third rotating shaft 3 (with a shaft sleeve 12 outside) , The fourth rotating shaft is installed on the wallboard 6 . On the first opening and closing seat 8 or the second opening and closing seat, drive the first roller through the transmission mode of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com