Full-automatic double-work-station screen printing machine

A dual-station, screen printing machine technology, applied in screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of inconvenient maintenance, complex structure, low efficiency, etc., to meet mass production, maintenance convenience, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

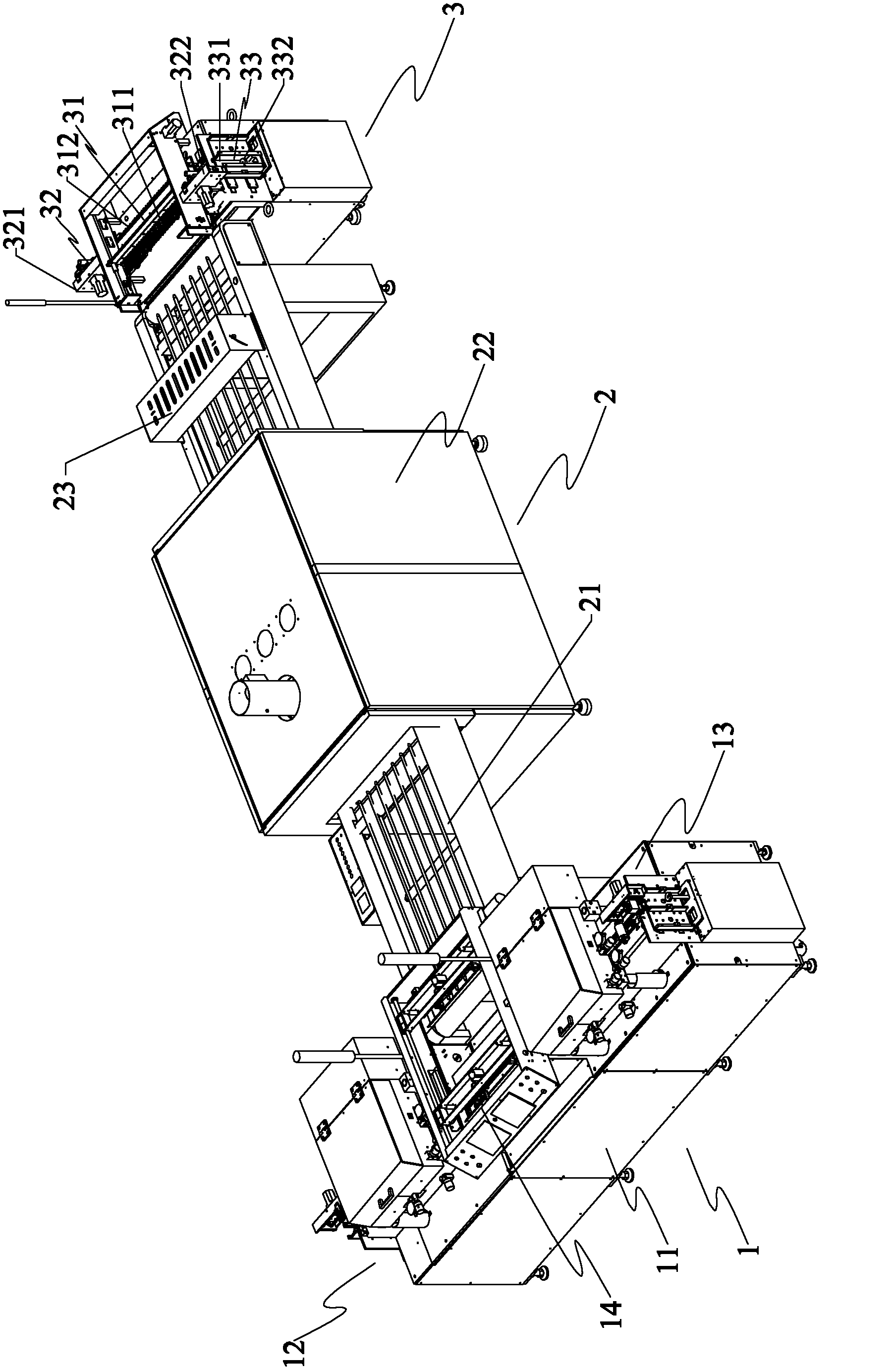

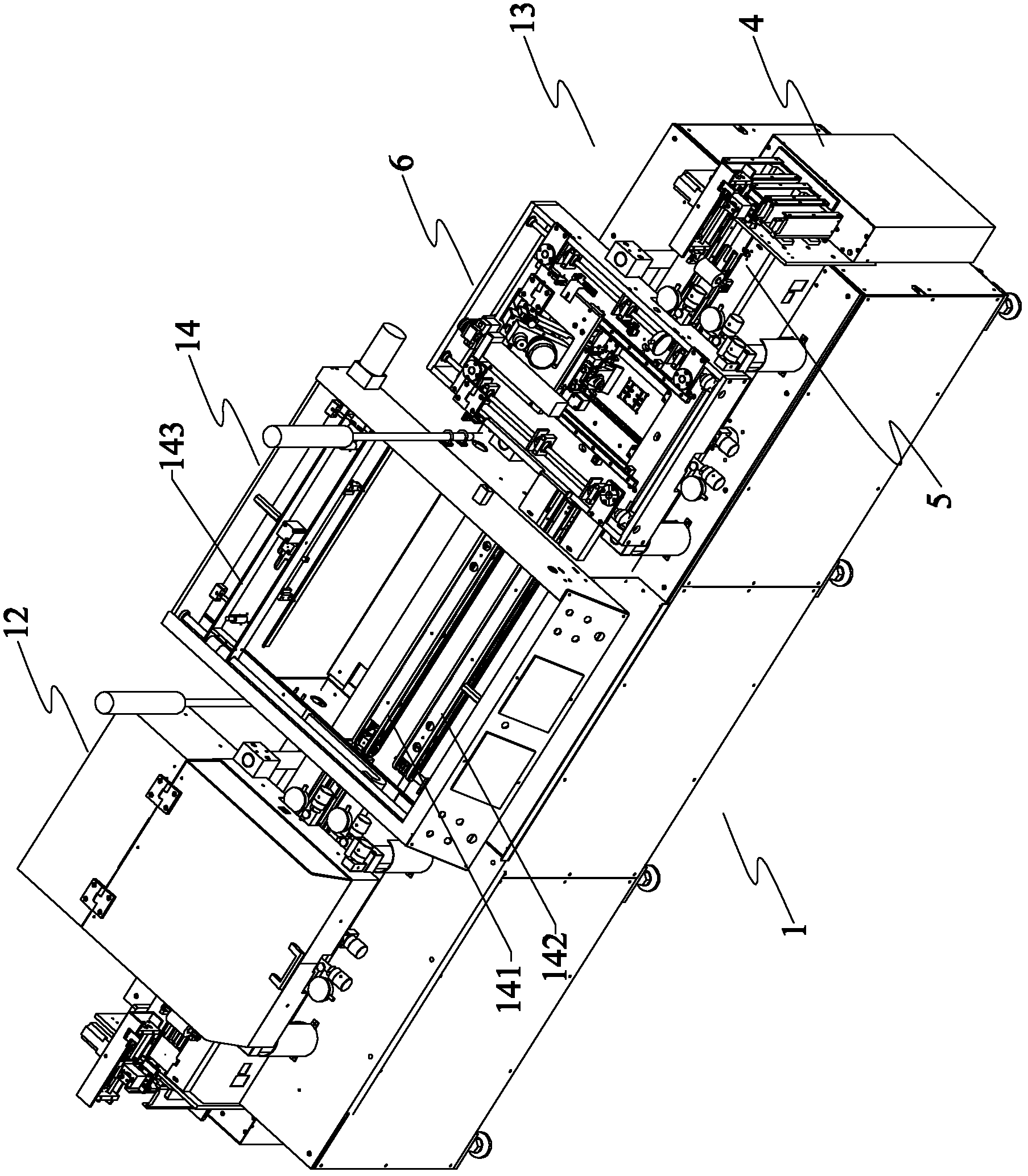

[0025] Such as figure 1 As shown in 7, the automatic double-station screen printing machine of the present invention includes a printing system 1, a drying system 2, a receiving system 3 and an electric control system.

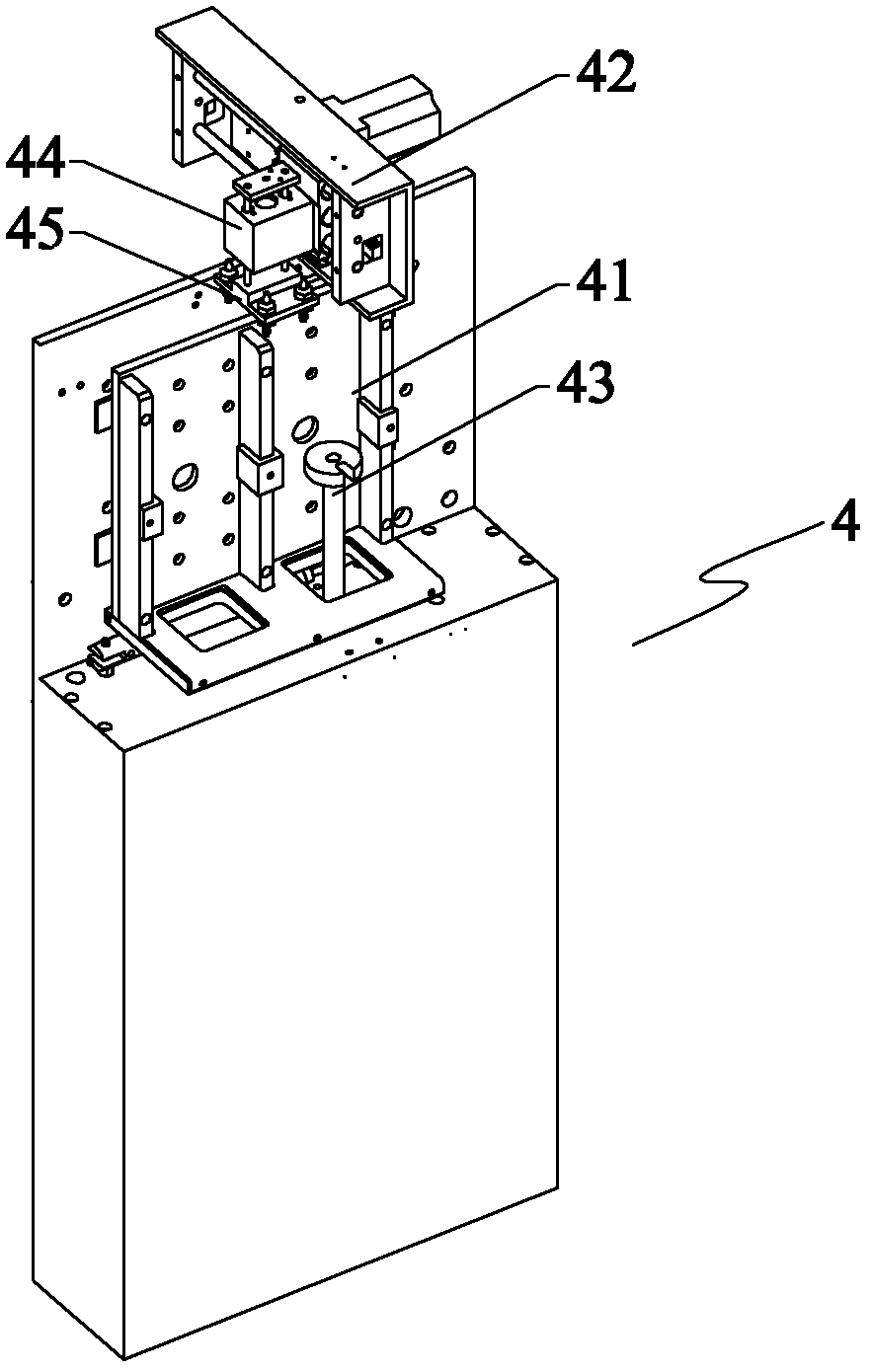

[0026] The above-mentioned printing system 1 includes a base 11, a left station printing device 12 and a right station printing device 13 which are installed above the base and are independent of each other, and an overall printing device arranged between the left station printing device and the right station printing device. Flat device 14, wherein each station printing device 12, 13 includes a feeding mechanism 4, a substrate transfer positioning mechanism 5 and a screen printing mechanism 6 with matching actions.

[0027] Further, the feeding mechanism 4 is arranged on the end side of the base 11 and is adjacent to the substrate transfer positioning mechanism 5, which includes a substrate feeding chute 41 and a feeding transfer robot 42, wherein: the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com