Screen printing process for a plurality of mobile phone glass lenses at one time

A glass lens and screen printing technology, which is applied to screen printing machines, lenses, printing, etc., can solve problems such as glass lens screen printing efficiency, achieve the effects of reducing production costs, reducing operating intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

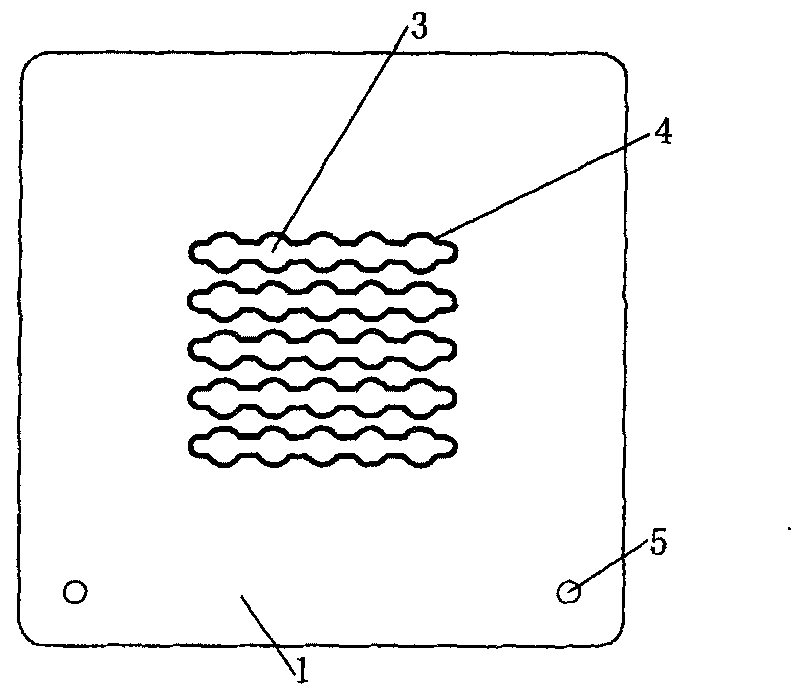

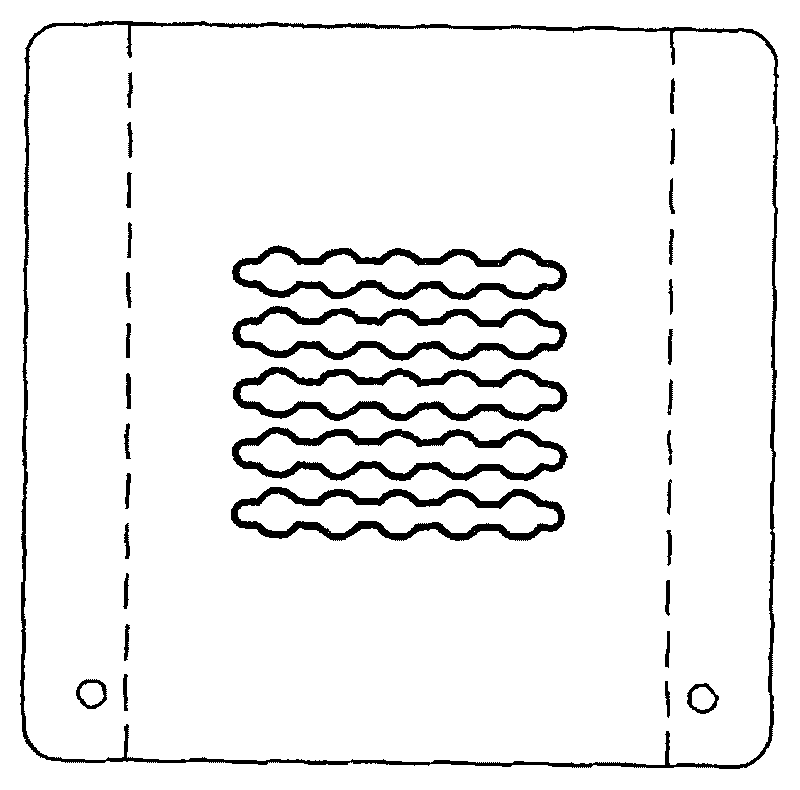

[0021] The present invention will be further described below in conjunction with accompanying drawing.

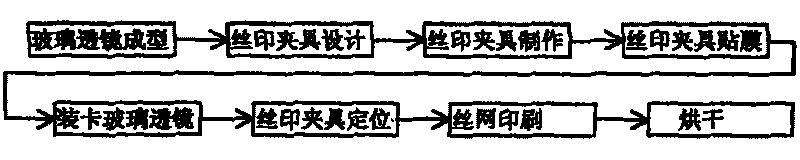

[0022] The technological process of the present invention is: glass lens forming→silk printing fixture design→silk printing fixture making→silk printing fixture film processing→fitting glass lens→silk printing fixture positioning→screen printing→drying (see figure 1 ). Its specific process steps are as follows:

[0023] (1) Glass lens molding: The traditional mobile phone flat glass lens preparation process is used to prepare glass lenses that meet the requirements through cutting, rough grinding, molding and polishing.

[0024] In order to ensure the positional accuracy of screen printing, it is necessary to control the tolerance of the outer dimension of the glass during molding, which generally needs to be controlled at D+ / -0.02mm (D is the standard diameter of the glass lens), and the thickness of the glass is usually controlled at T+ / -0.02mm (T is the standard thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com