Silk-screen printing preparation method of spliced colored glaze glass

A technology of screen printing and glass, applied in the direction of printing, printing devices, etc., can solve the problems of unsightly effect, difficult installation, trouble, etc., and achieve the effect of omitting the adjustment process, avoiding the difference of color, and ensuring the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

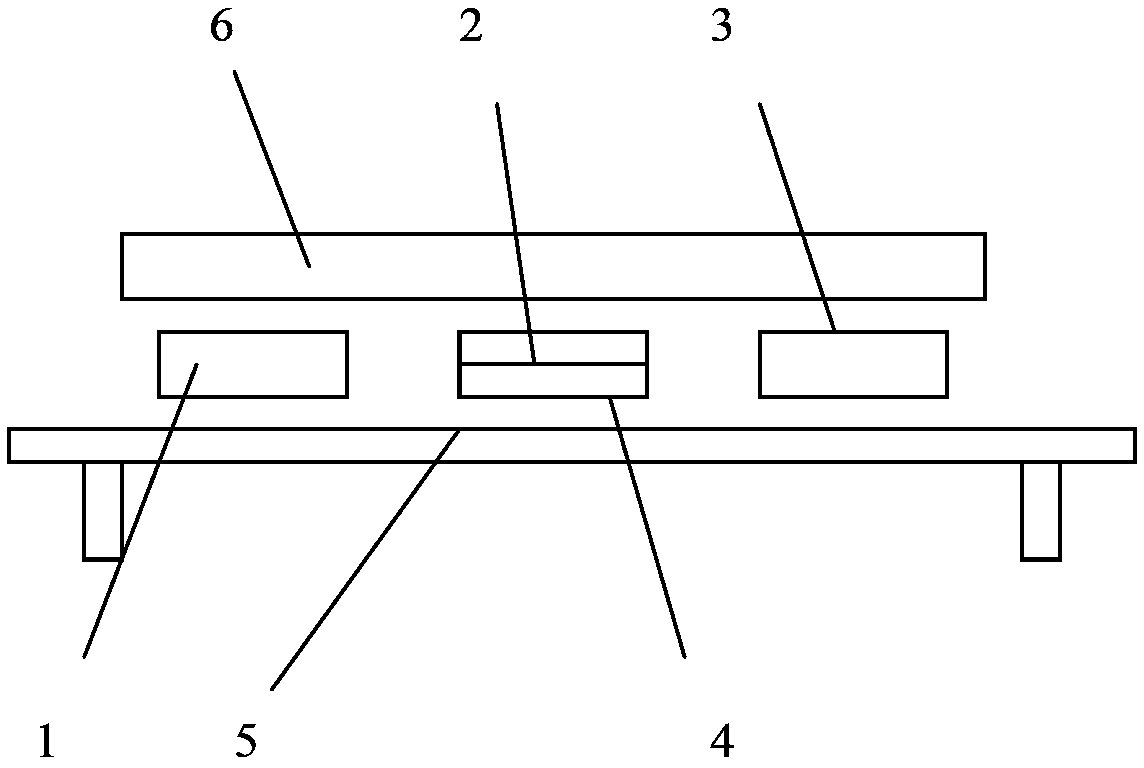

Method used

Image

Examples

Embodiment 1

[0023] 1. Variety: 10 ultra-white red gradient glaze LOW-E homogeneous + 16AR knot + 8 ultra-white red gradient glaze homogeneous + 1.52SGP + 8 ultra-white homogeneous

[0024] 2. Specifications: 1484mm*4972mm (maximum processing size)

[0025] 3. Application and purpose: The Beijing Olympic Museum project is designed with a large number of 8mm ultra-white, 10 ultra-white LOW-E glass and 1.52SGP film, showing extremely high sunlight transmittance and energy-saving effect. This splicing colored glaze glass is a red double gradient colored glaze interlayer insulating glass. The red colored glaze replaces the traditional white ordinary glass, which visually enhances the unique effect of the building. It is printed with a red gradient pattern and colored glaze, which finally echoes the overall architecture of the bird's nest.

[0026] 4. Process technology: The traditional screen printing method can only print one piece of glass at a time. Because the glaze pattern of the Bird's...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com