Automatic contraposition method and system for screen process press

A screen printing machine, automatic alignment technology, applied in screen printing machines, general parts of printing machinery, printing machines, etc., can solve the problem of low production efficiency, high labor intensity of operators, screen and substrate alignment Inaccuracy and other problems, to improve production efficiency, ensure alignment accuracy, and achieve the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

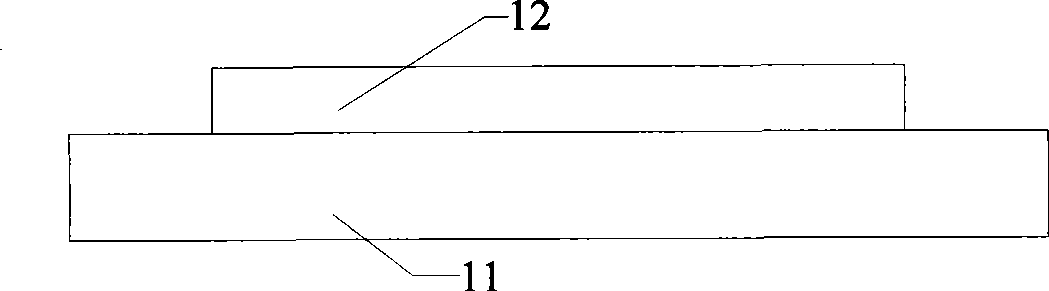

[0035] In the screen printing machine of the present invention, the screen plate is designed as a fixed type, and the printing platform is designed as a movable type, and then an image capture mechanism such as a CCD lens is used to determine the deviation between the substrate and the reference position, thereby controlling the relative movement of the printing platform , Compensate the deviation between the substrate and the screen to achieve fully automatic precise alignment.

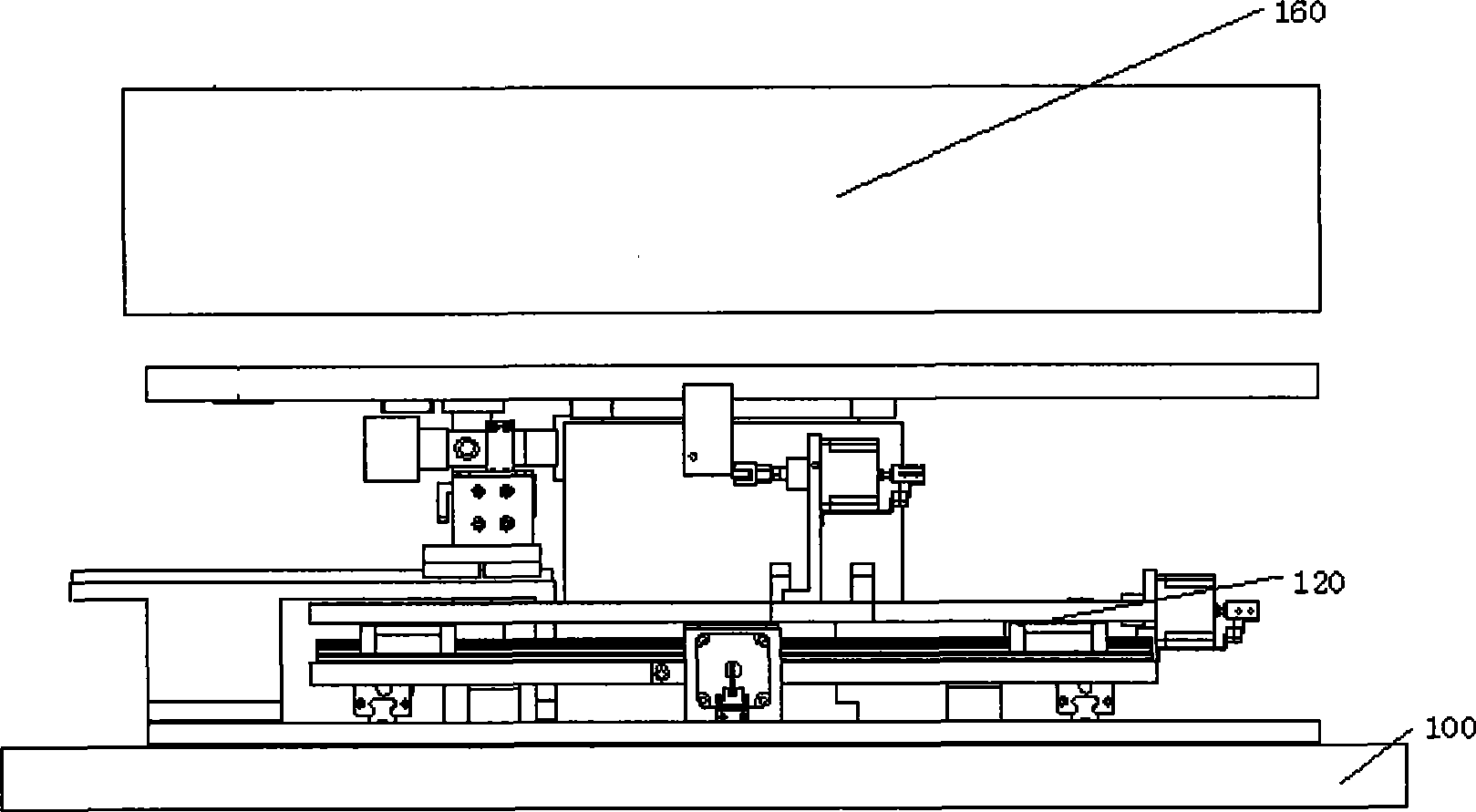

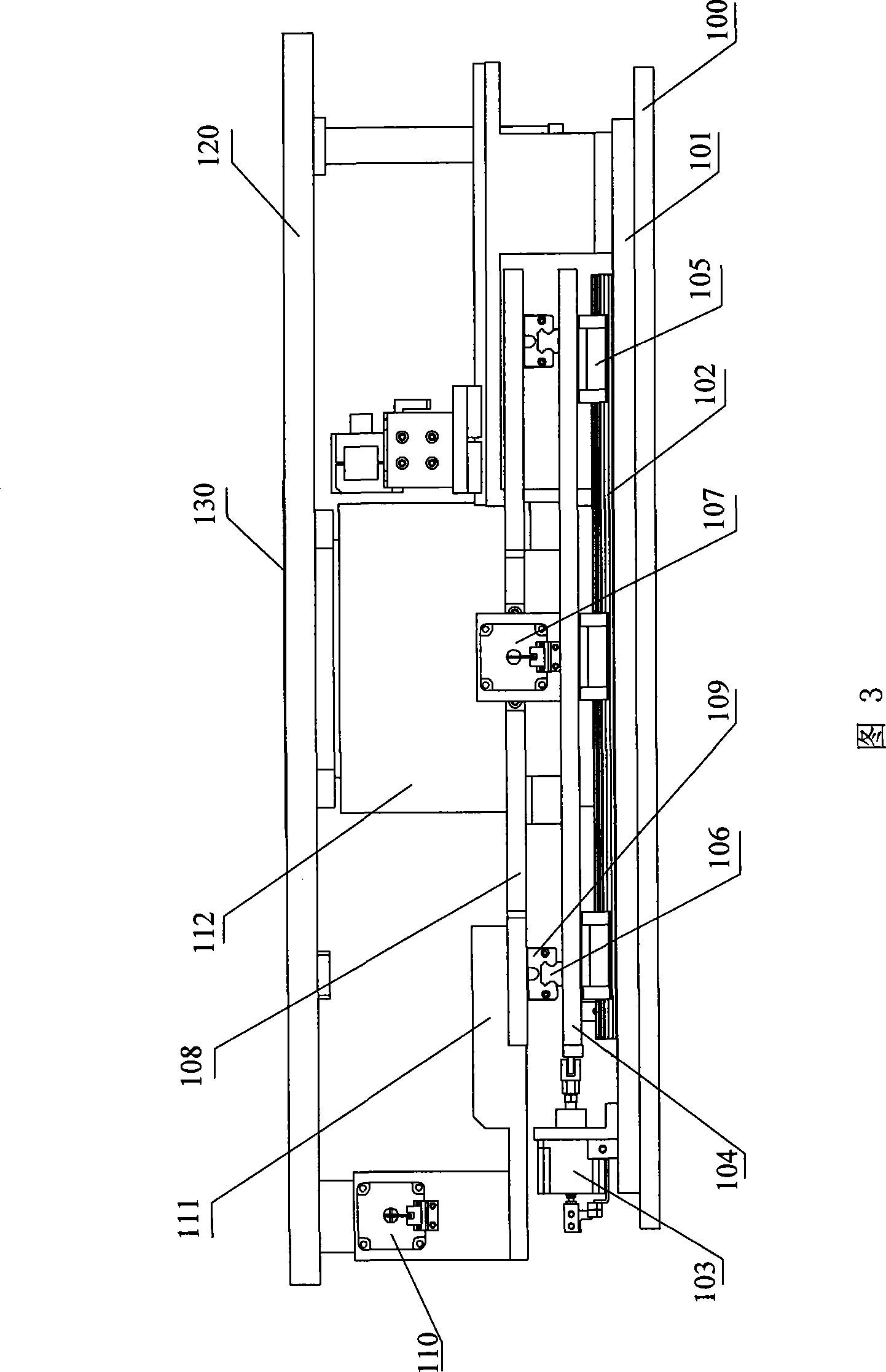

[0036] Such as figure 2 Shown is a schematic diagram of the overall structure of a screen printing machine according to an embodiment of the present invention, wherein the screen printing machine is mainly composed of a frame 100, a movable platform 120 and a machine head 160, and the printing head and the screen plate are installed on the machine head 160 . Referring specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com