A screen printing machine with self-alignment function of overprinting

A screen printing machine and self-alignment technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as unsatisfactory, precision errors, etc., to improve production efficiency, realize full automation, and avoid errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

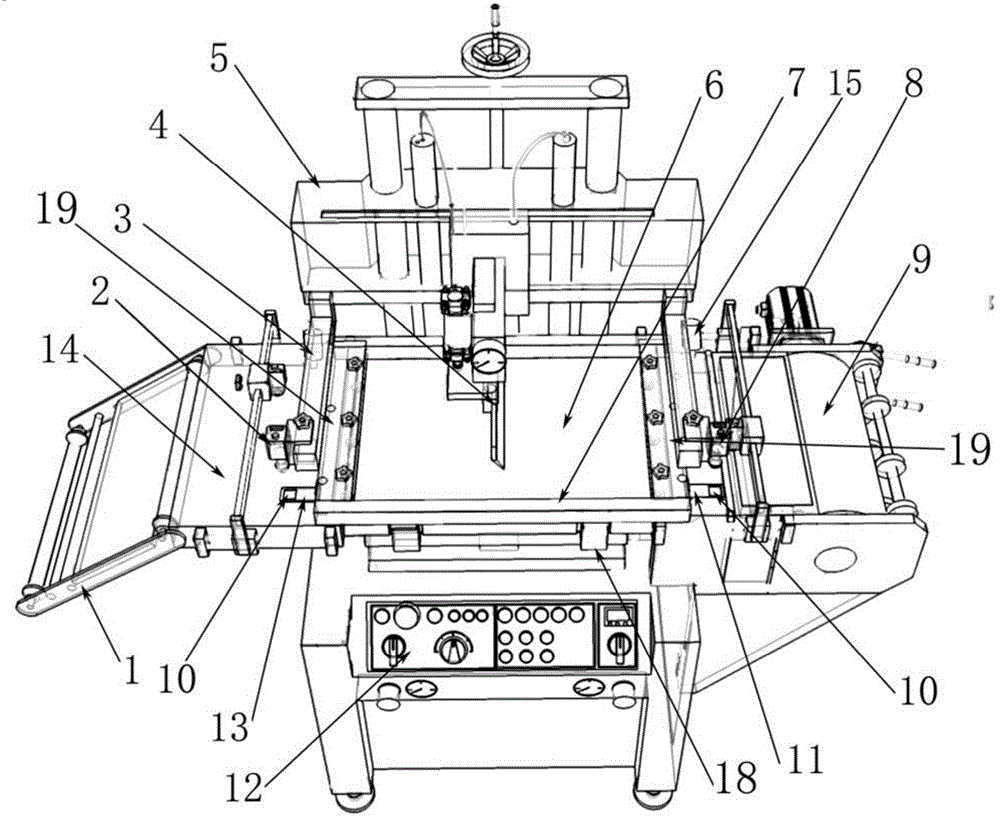

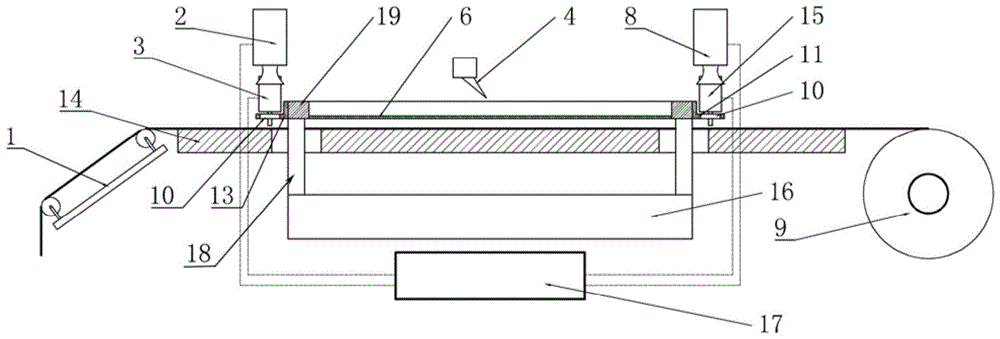

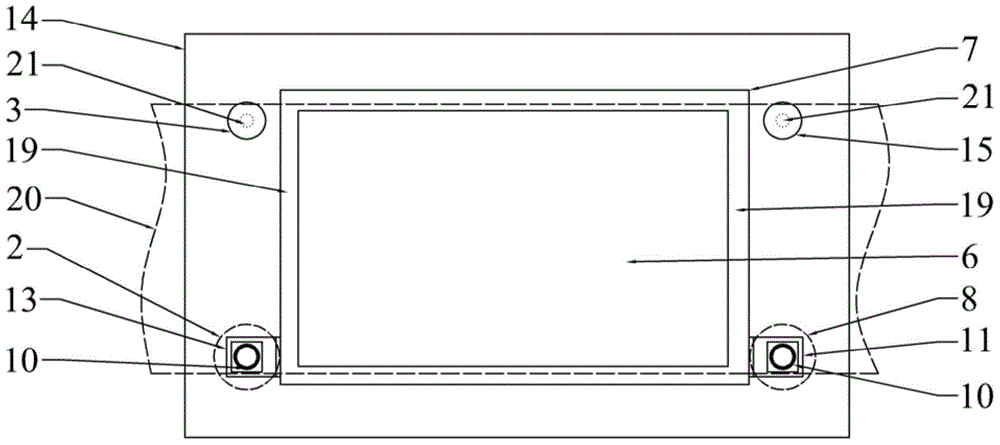

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

[0020] like Figure 1-2 As shown, the labels represent:

[0021] Conveyor frame 1, first CCD camera 2, first puncher 3, scraper 4, frame 5, screen plate 6, screen frame 7, second CCD camera 8, receiving roller 9, positioning hole 10, second Positioning part 11, control panel 12, first positioning part 13, printing plate 14, second puncher 15, driving mechanism 16, computer 17, column 18, longitudinal frame edge 19, web traveling area 20, punching knife 21 ,.

[0022] see Figure 1-3 As shown, a screen printing machine with overprint self-alignment function is provided in this embodiment, which includes a frame 5, and the frame 5 is fixedly provided with a computer 17 and a printing platform 14, wherein the computer 17 is arranged on the frame 5 In the inner space of the lower end ( figure 1 (not shown), the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com