Patents

Literature

34results about "Specific circuit substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

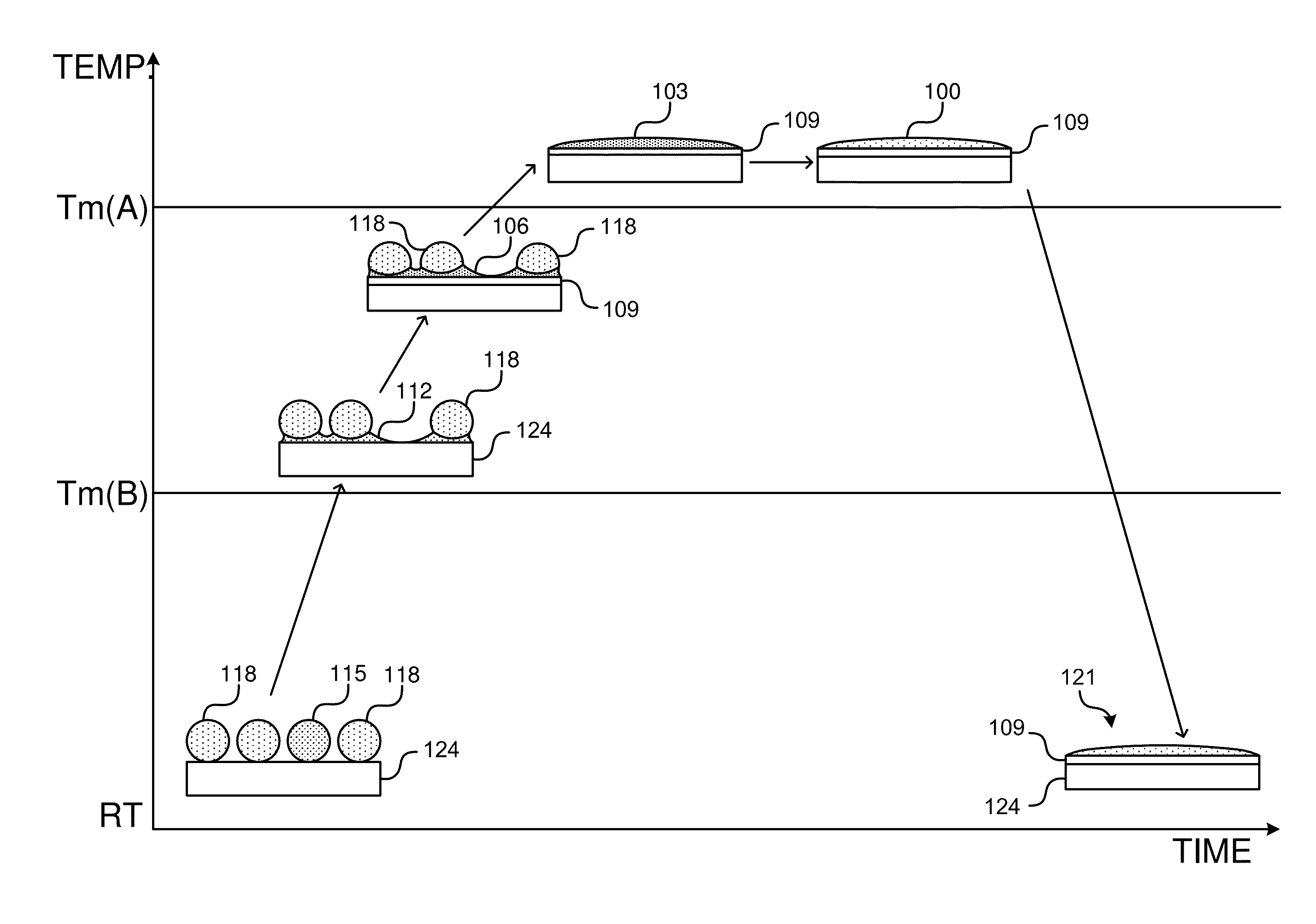

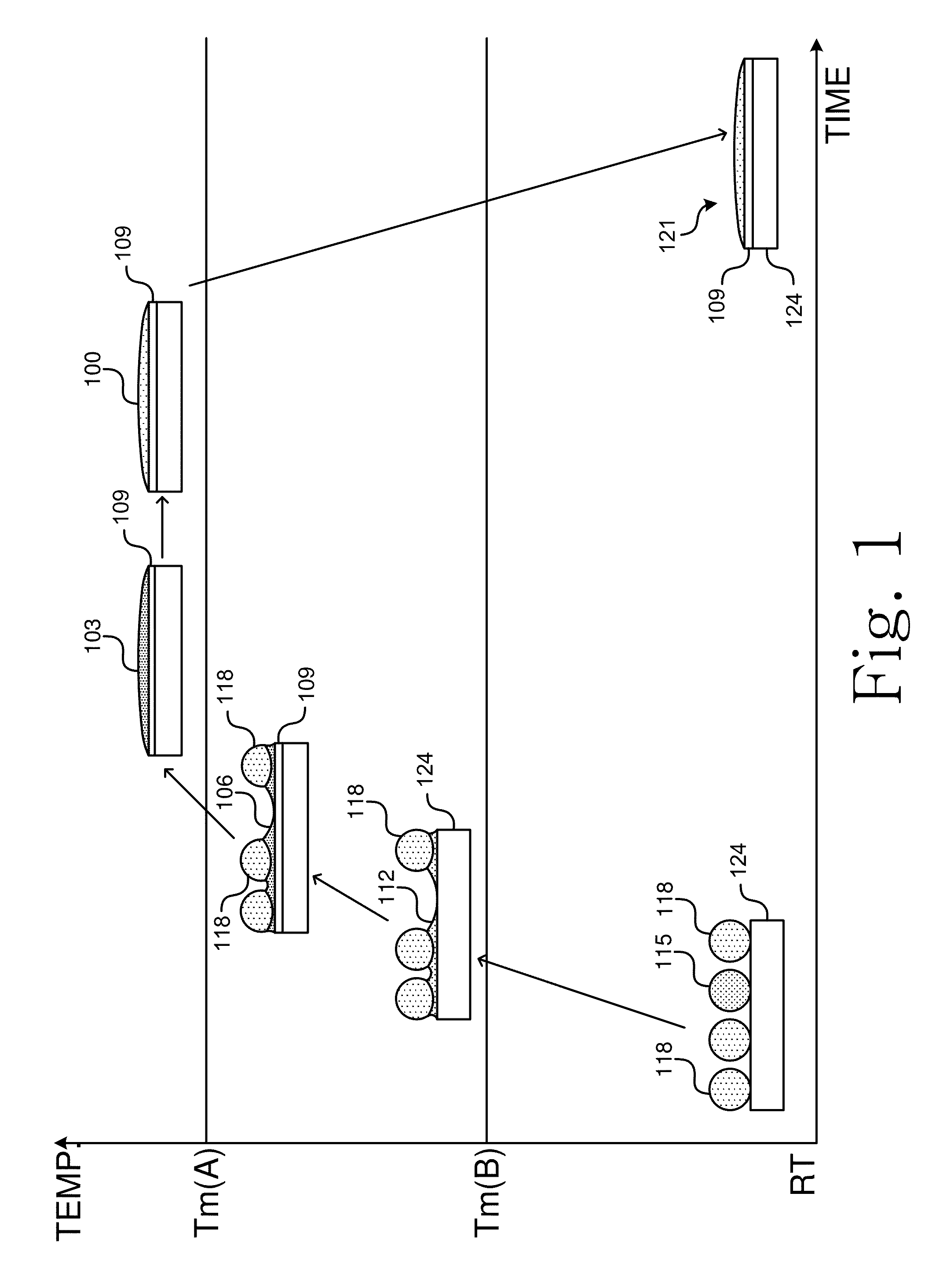

Cream solder and method of soldering electronic part

ActiveUS20120018048A1Improve adhesionHigh strength stabilityPrinted circuit assemblingPrinted circuit aspectsThermal stabilityUltimate tensile strength

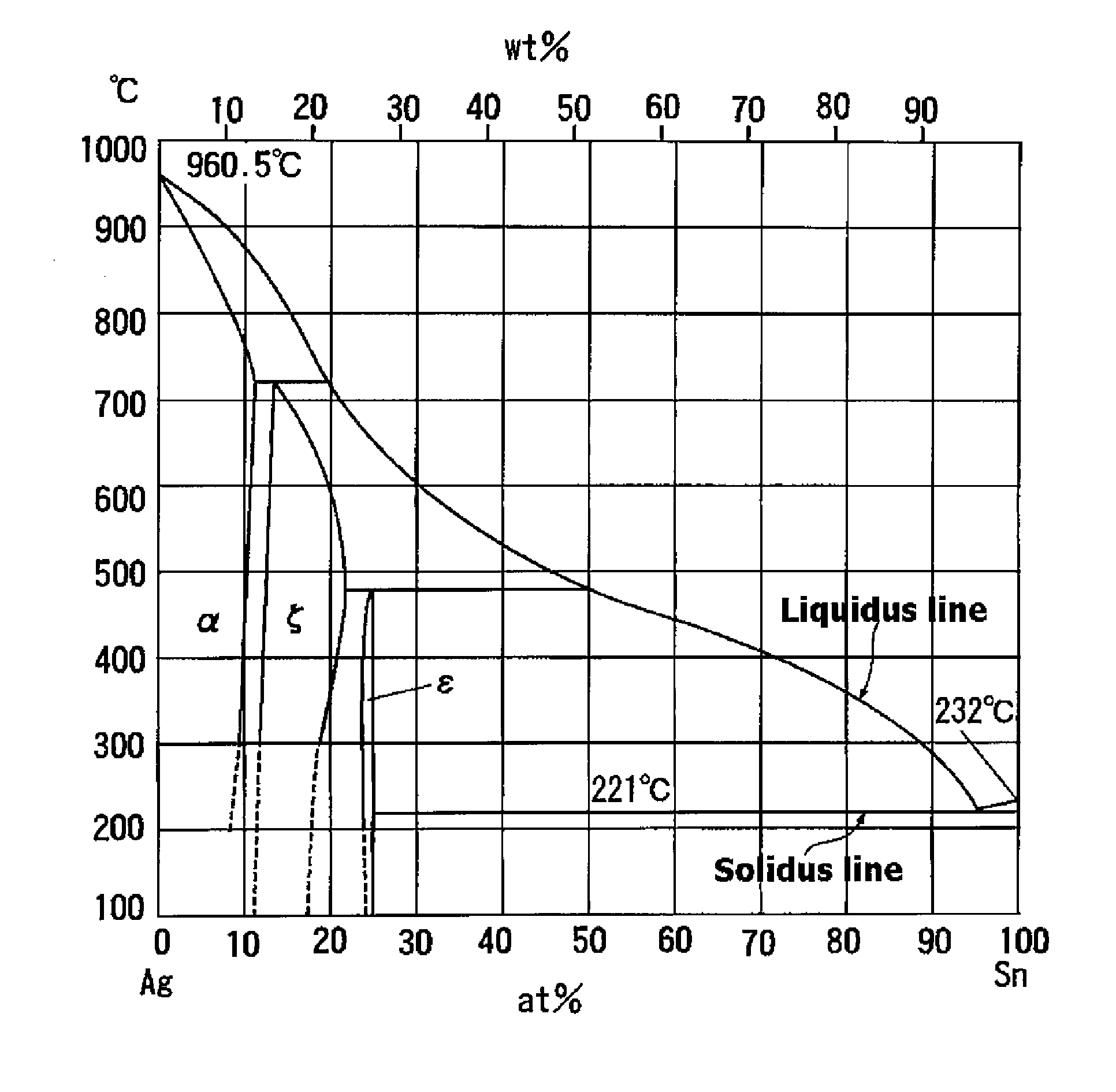

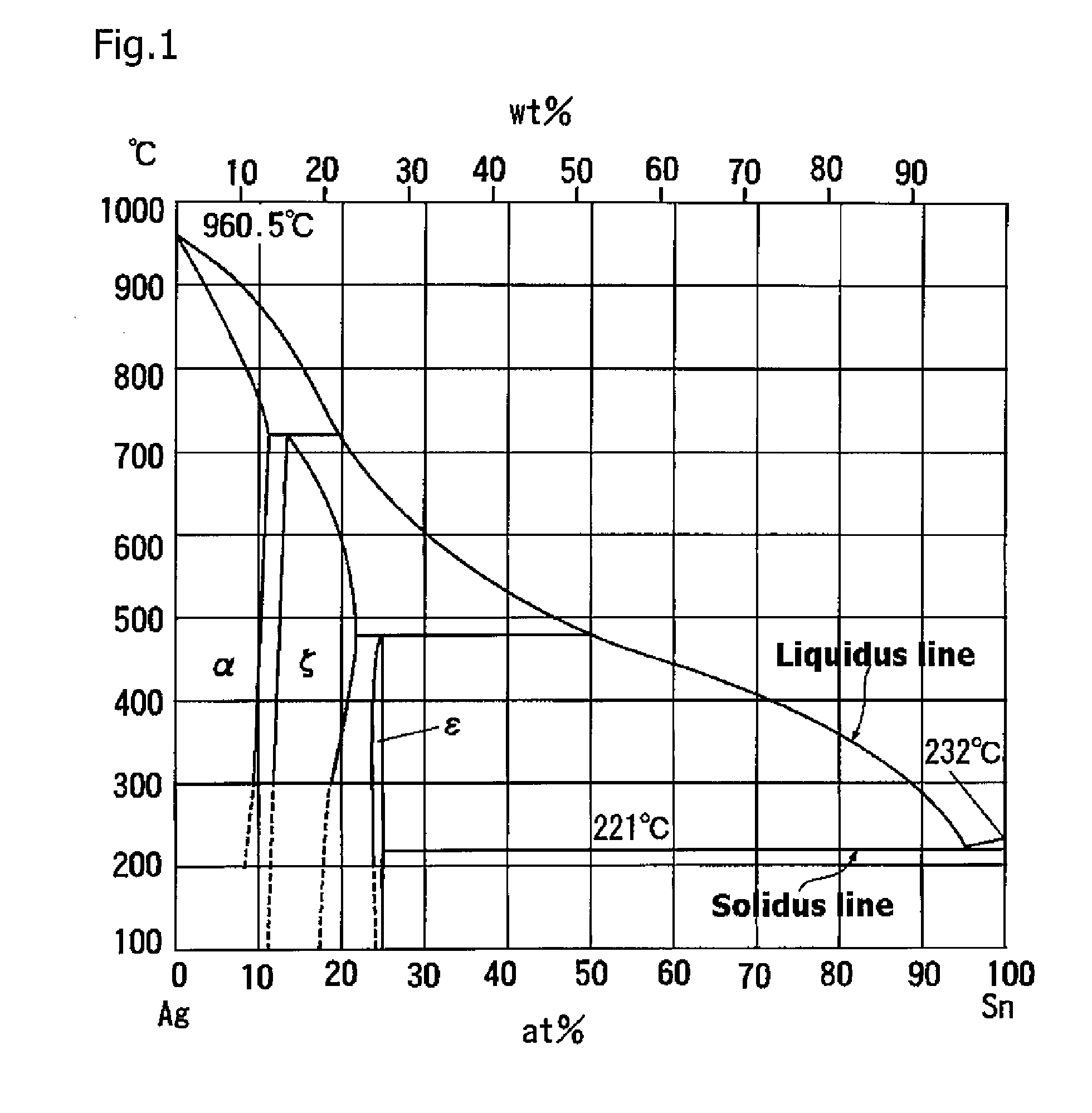

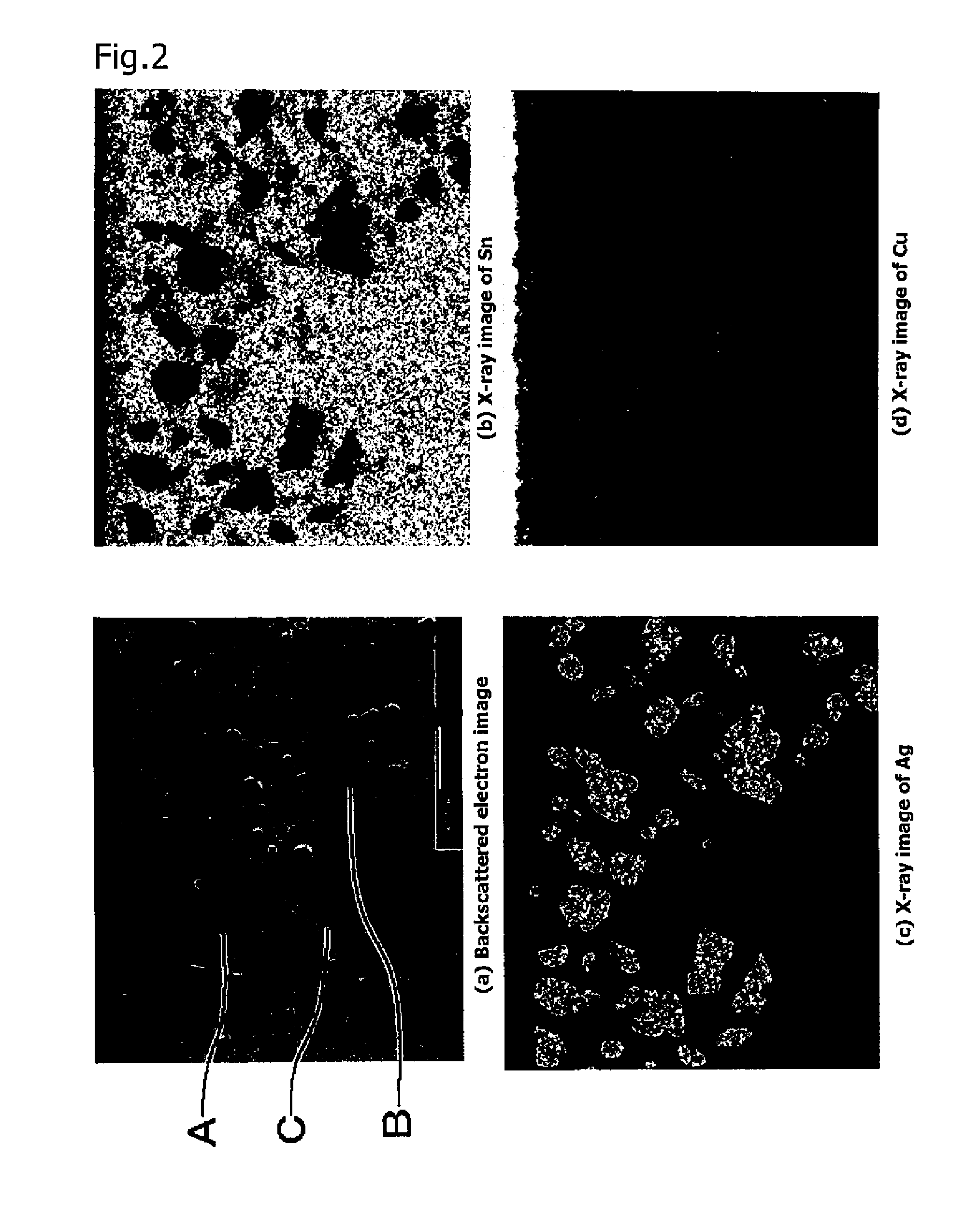

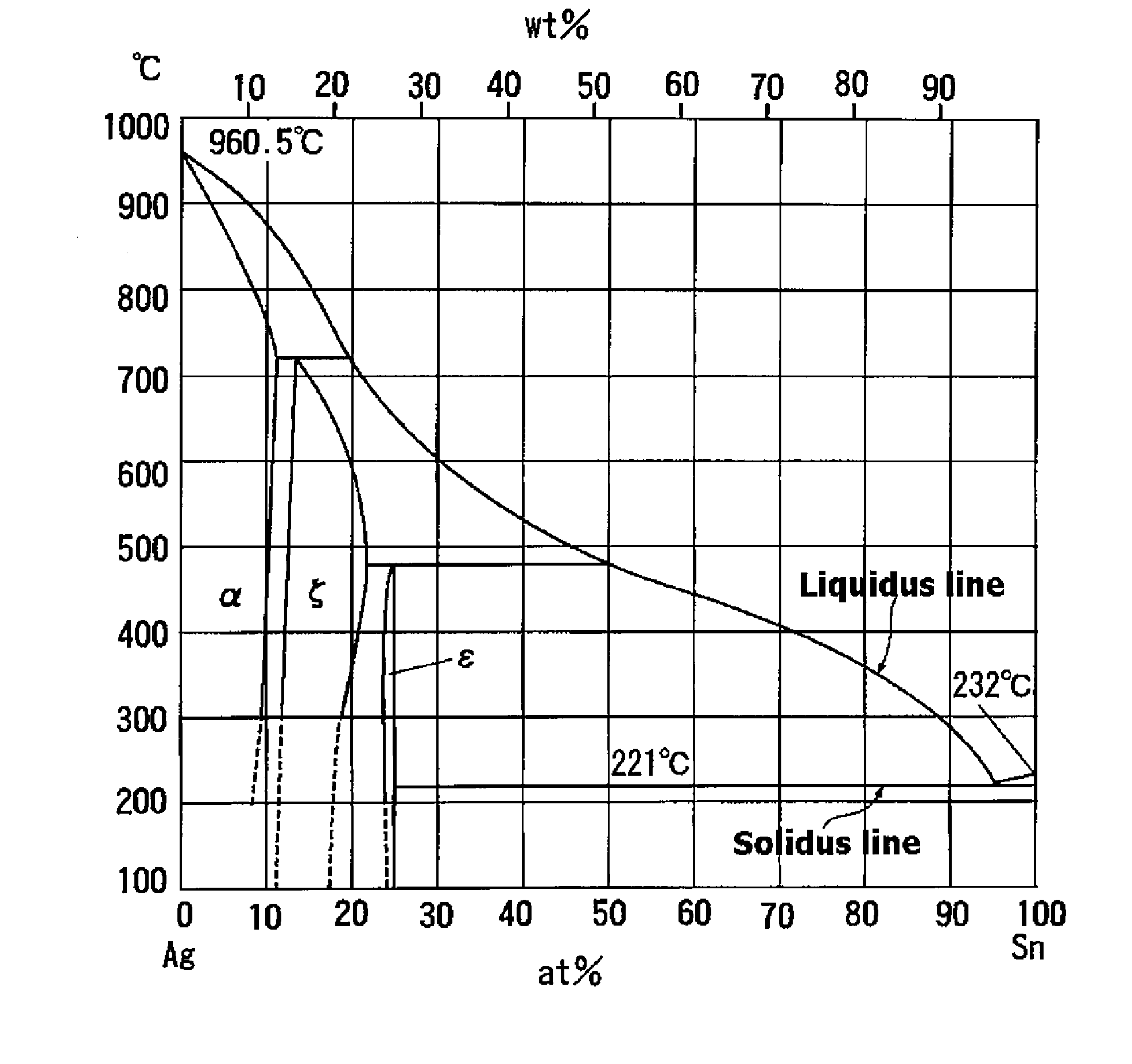

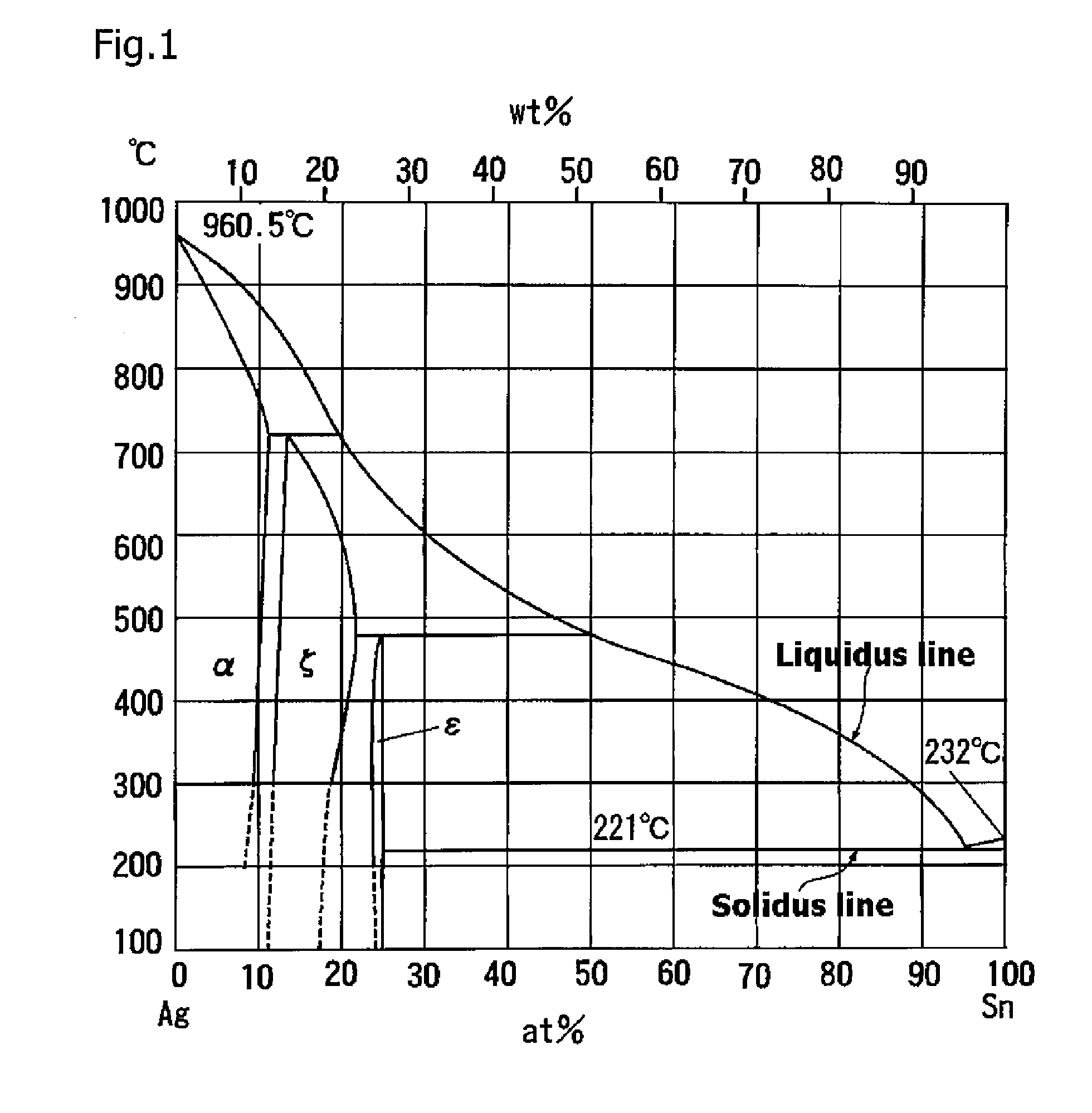

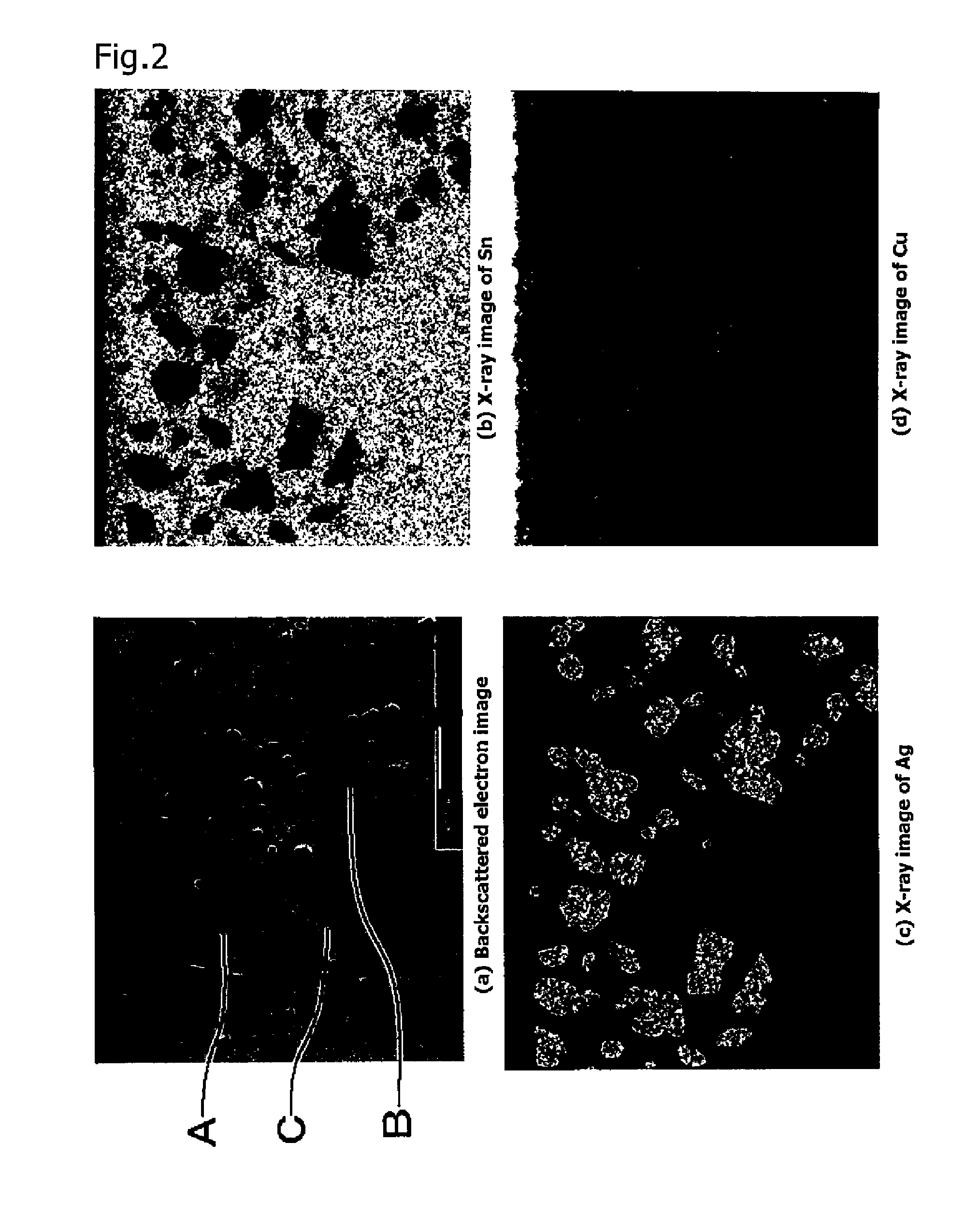

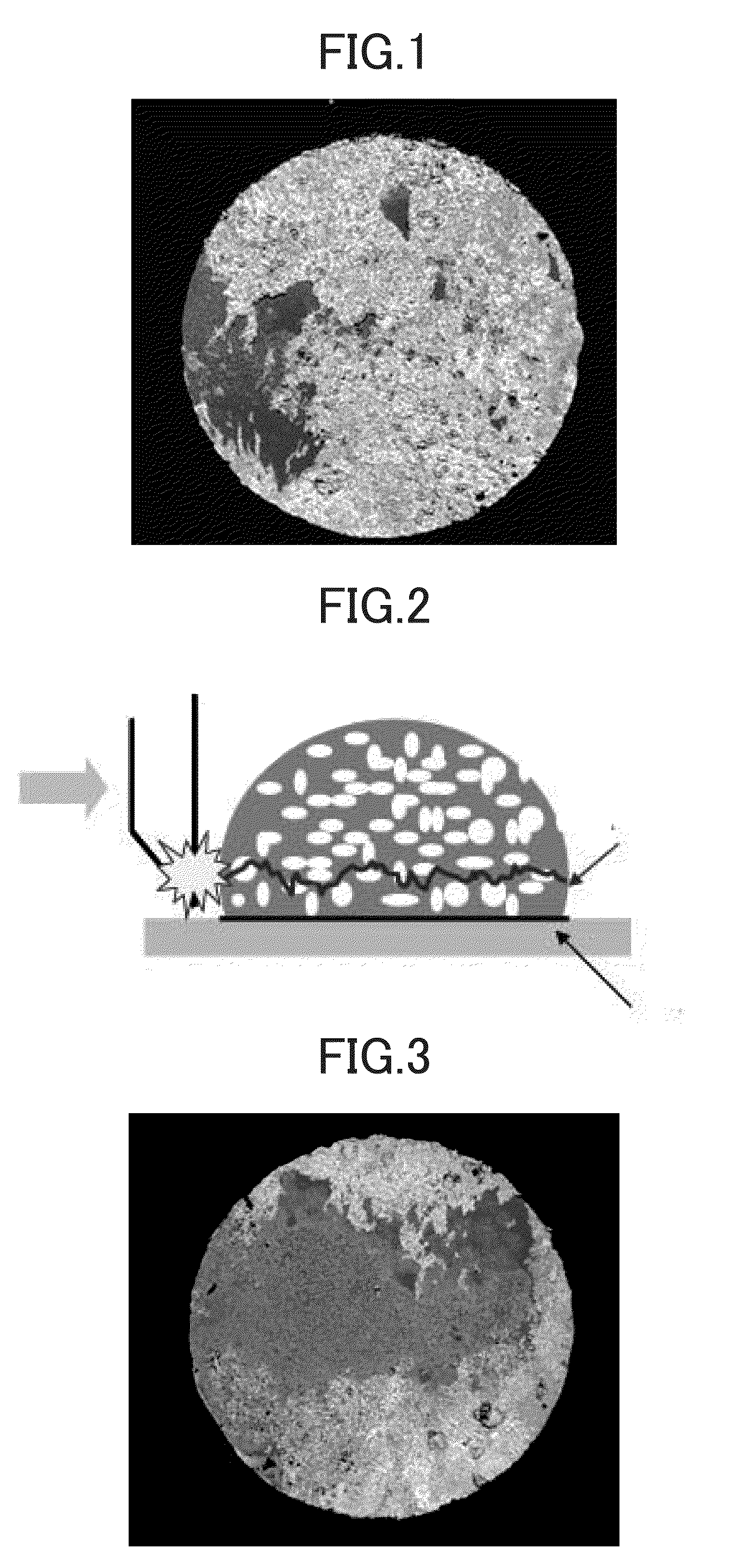

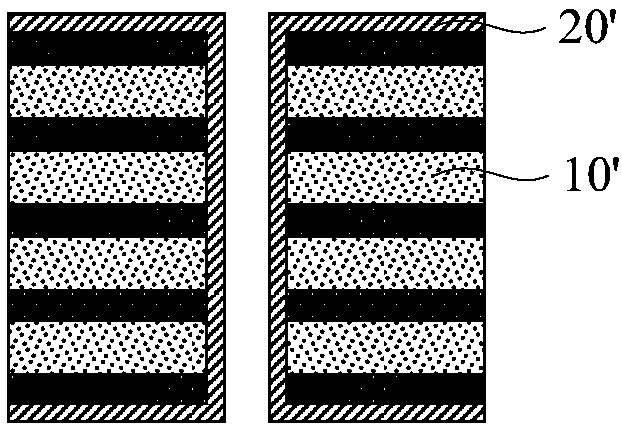

A cream solder obtained by kneading an Sn—Ag—Cu alloy together with a flux, wherein the Sn—Ag—Cu alloy includes a mixture of a first powdery alloy and a second powdery alloy, the first powdery alloy is represented by an Sn—Ag phase diagram having a solid-liquid coexistence region and has a given silver amount which is larger than that in the eutectic composition (3.5 wt. % silver), and the second powdery alloy has a silver amount which is that in the eutectic composition (3.5 wt. % silver) or which is close to that in the eutectic composition and is smaller than that in the first powdery alloy. This cream solder has excellent strength and thermal stability, and satisfactory bonding properties. It is based on an inexpensive Sn—Ag—Cu solder alloy. It is suitable for use as a high-temperature-side lead-free solder material conformable to temperature gradation bonding. Also provided is a method of soldering.

Owner:NIHON HANDA +1

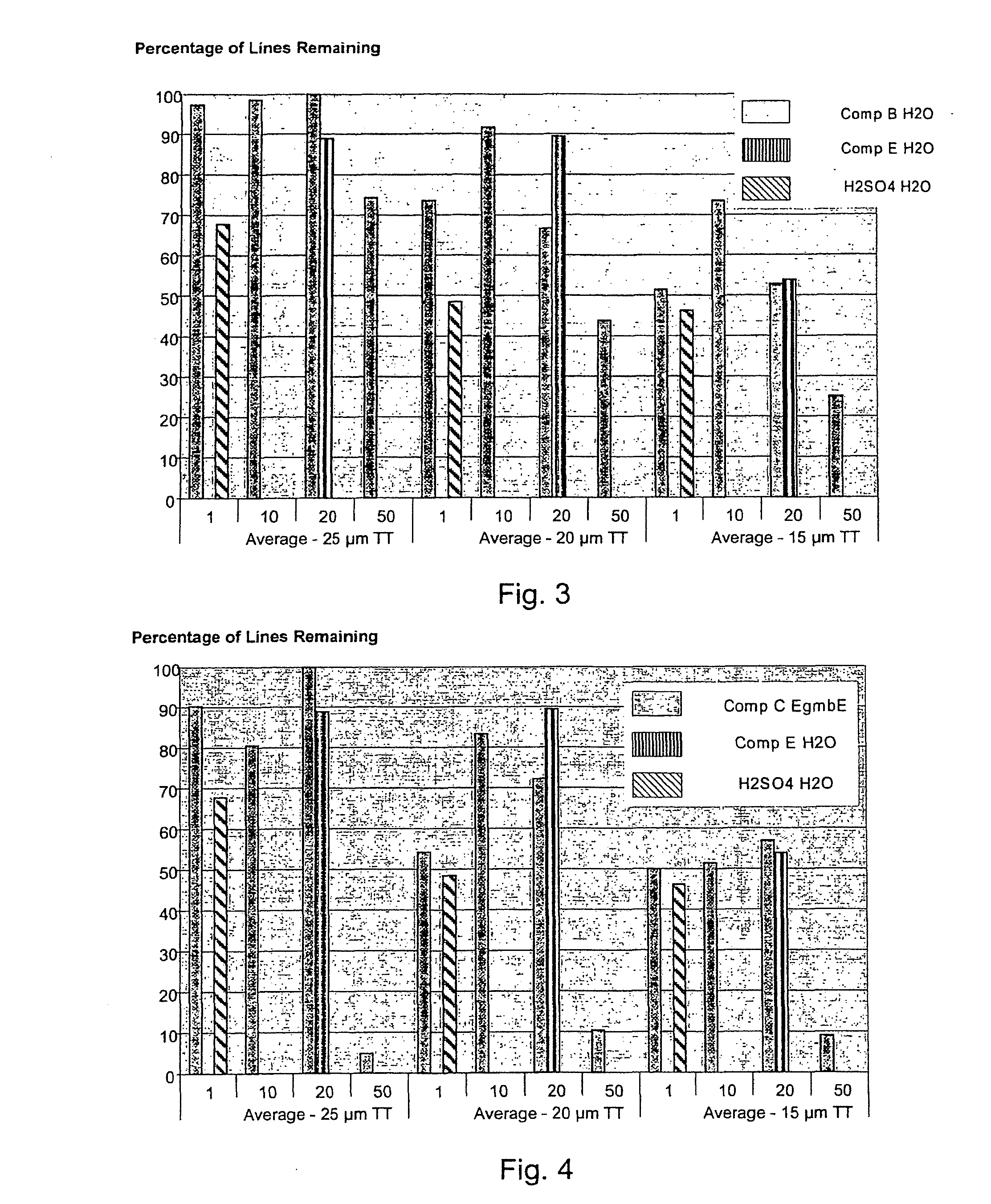

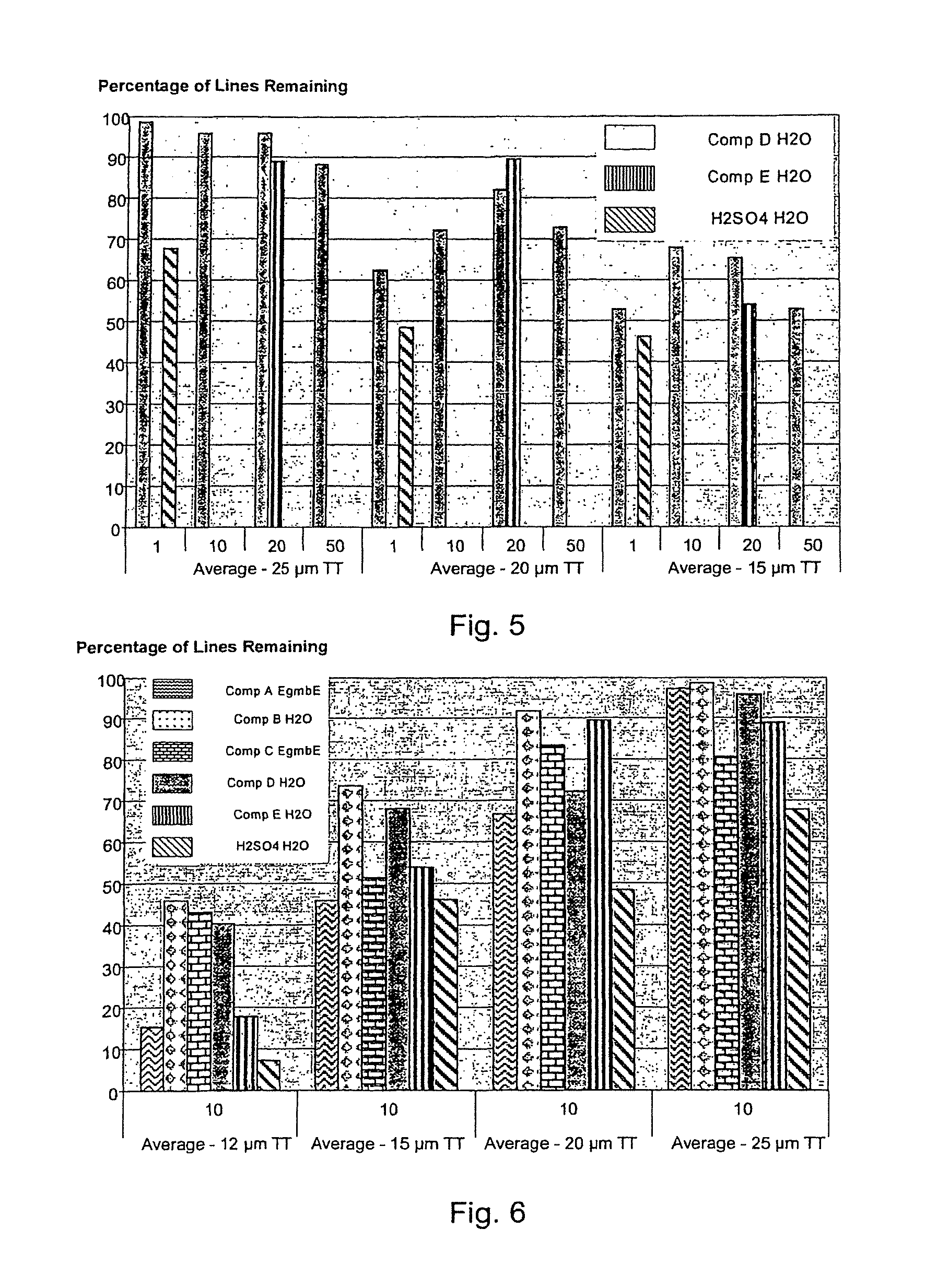

Non-Etching Non-Resist Adhesion Composition and Method of Preparing a Work Piece

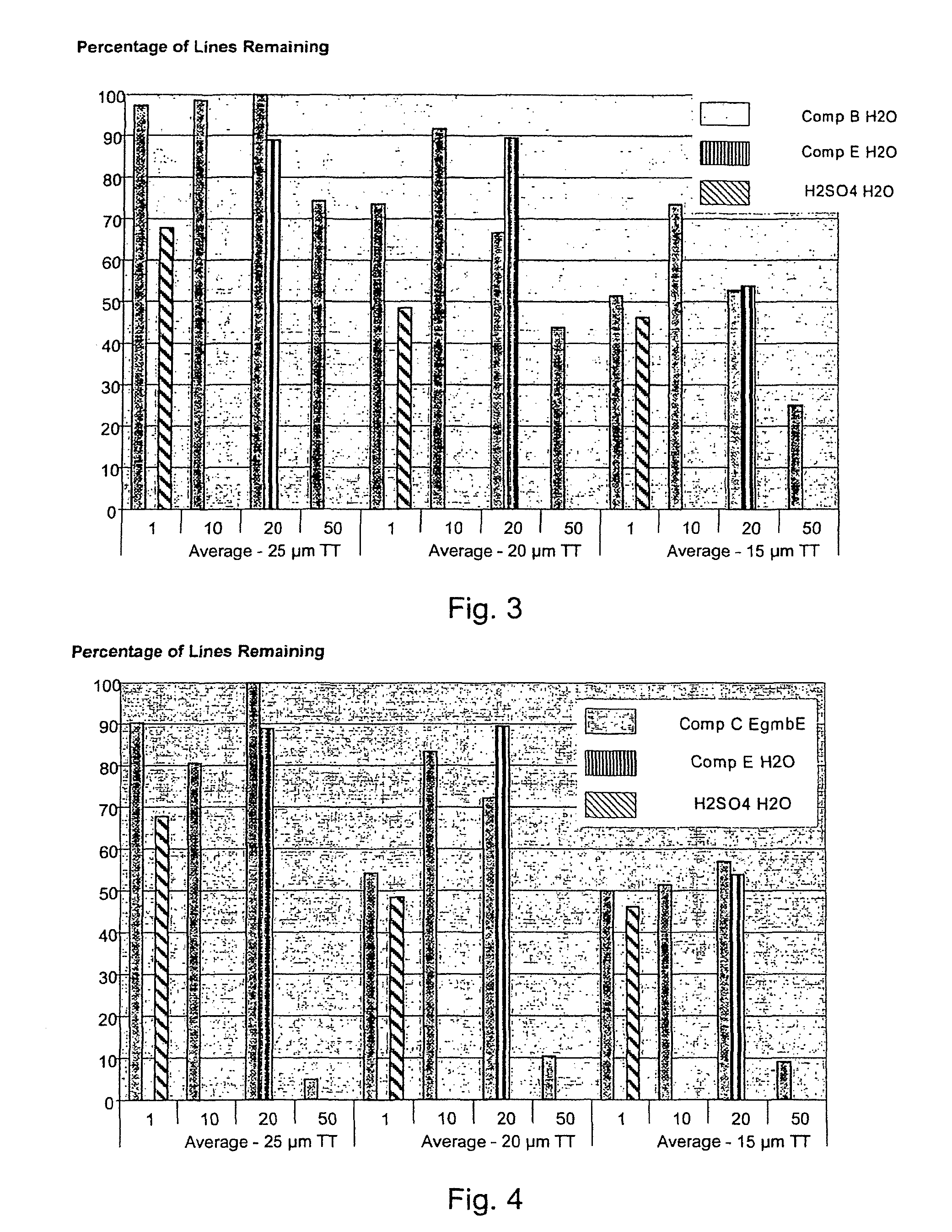

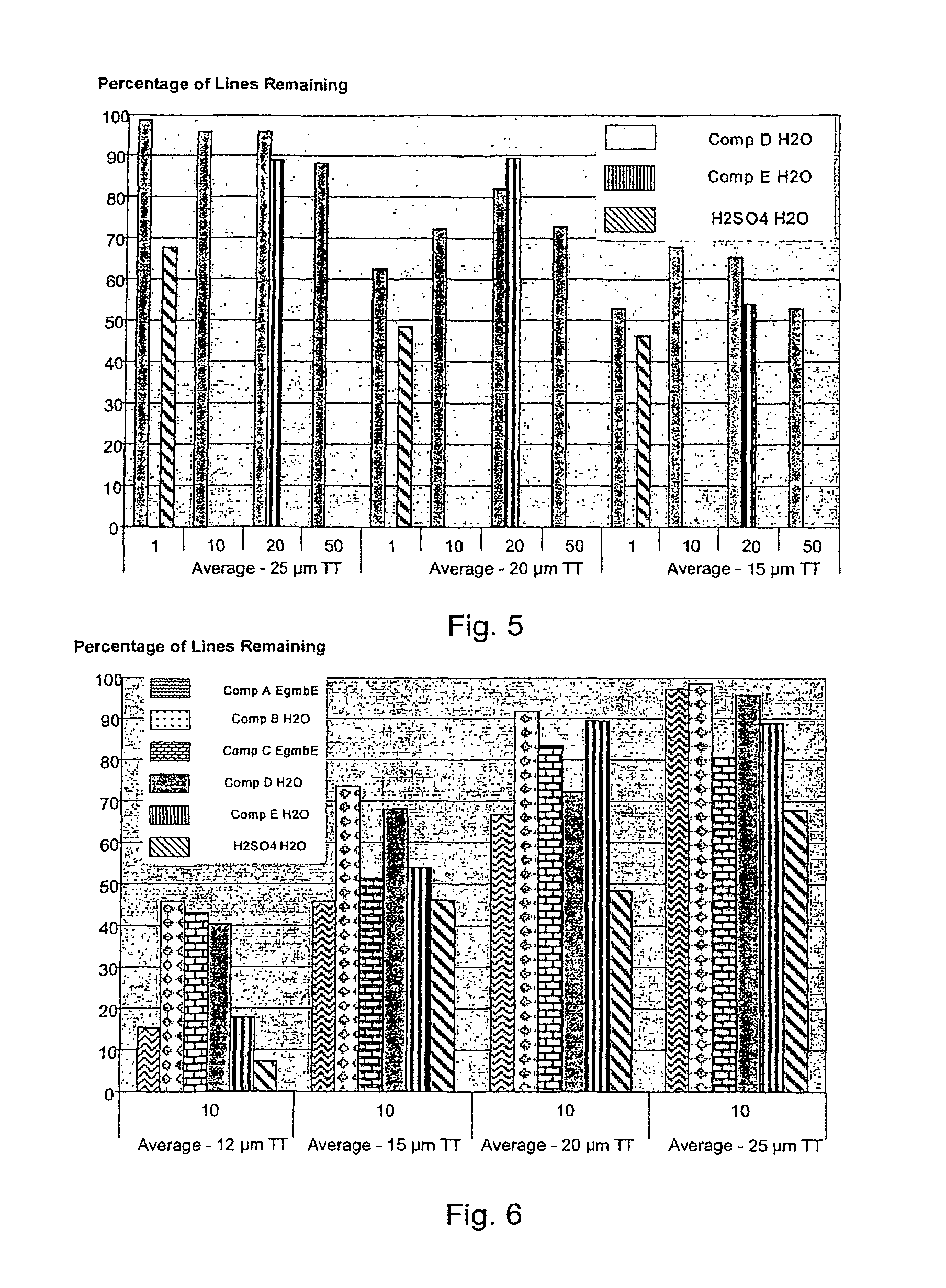

ActiveUS20100323099A1Improve adhesionImprove consistencyInsulating substrate metal adhesion improvementOrganic dyesResistThiol

To achieve good adherence of a resist coating, more specifically a photo imageable resist coating, to a copper base while ensuring that the copper base being very thin is not compromised, a non-etching non-resist composition for the treatment of the copper base is provided, said composition comprising at least one adhesion agent selected from the group comprising (i) heterocyclic compounds comprising at least one thiol moiety and (ii) quaternary ammonium polymers having the following general chemical formula: {N+(R3)(R4)—(CH2)a—N(H)—C(Y)—N(H)—(CH2)b—N+(R3)(R4)—R5}n2n X−, with R1, R2, R3, R4, R5, Y and X− being defined as claimed.

Owner:ATOTECH DEUT GMBH

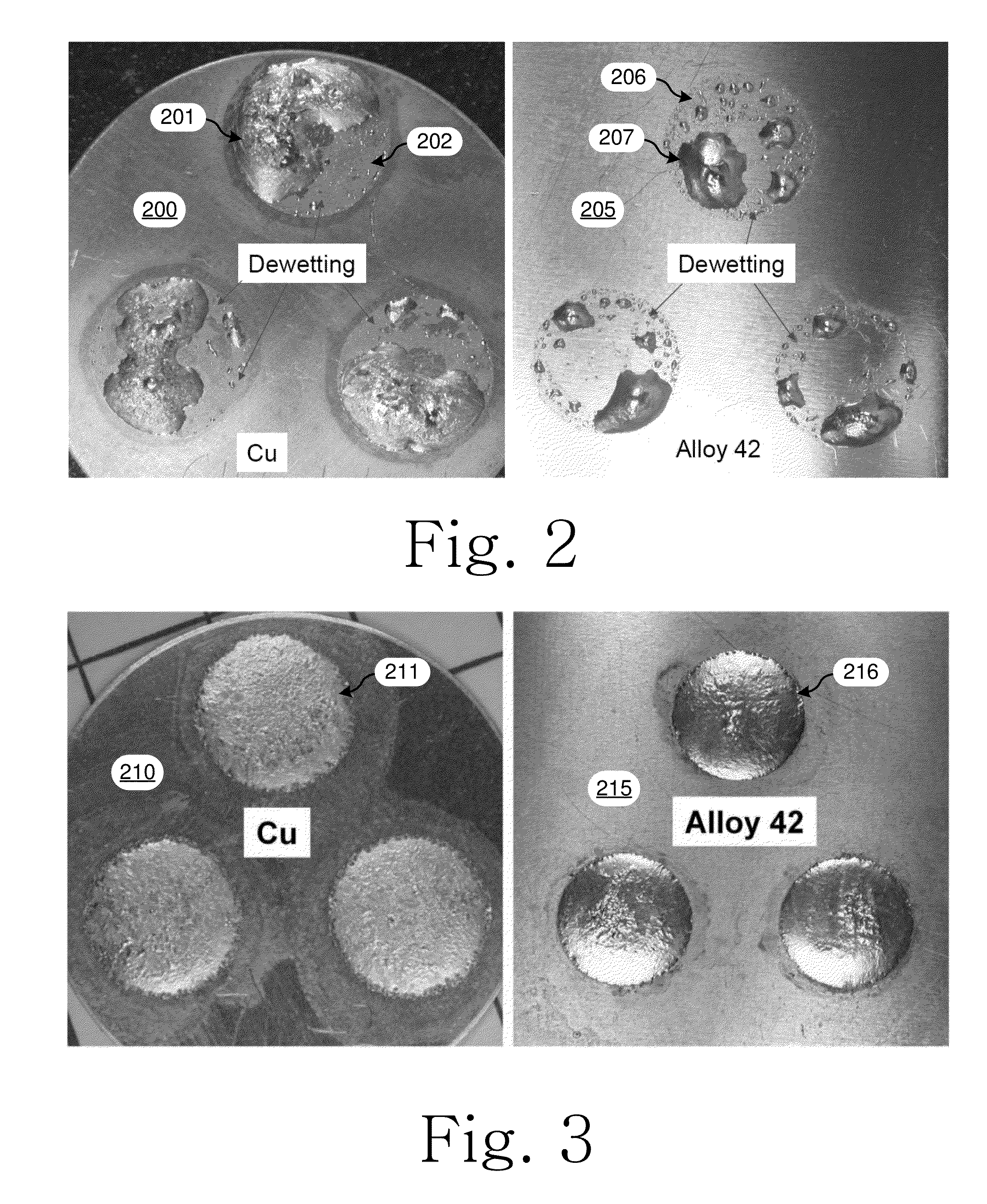

Mixed alloy solder paste

ActiveUS20150246417A1Improved reaction chemistryWell-controlled IMC layer thicknessPrinted circuit assemblingSolid-state devicesSolder pasteMaterials science

A solder paste consists of an amount of a first solder alloy powder between 44 wt % to less than 60 wt %; an amount of a second solder alloy powder between greater than 0 wt % and 48 wt %; and a flux; wherein the first solder alloy powder comprises a first solder alloy that has a solidus temperature above 260° C.; and wherein the second solder alloy powder comprises a second solder alloy that has a solidus temperature that is less than 250° C. In another implementation, the solder paste consists of an amount of a first solder alloy powder between 44 wt % and 87 wt %; an amount of a second solder alloy powder between 13 wt % and 48 wt %; and flux.

Owner:INDIUM CORPORATION

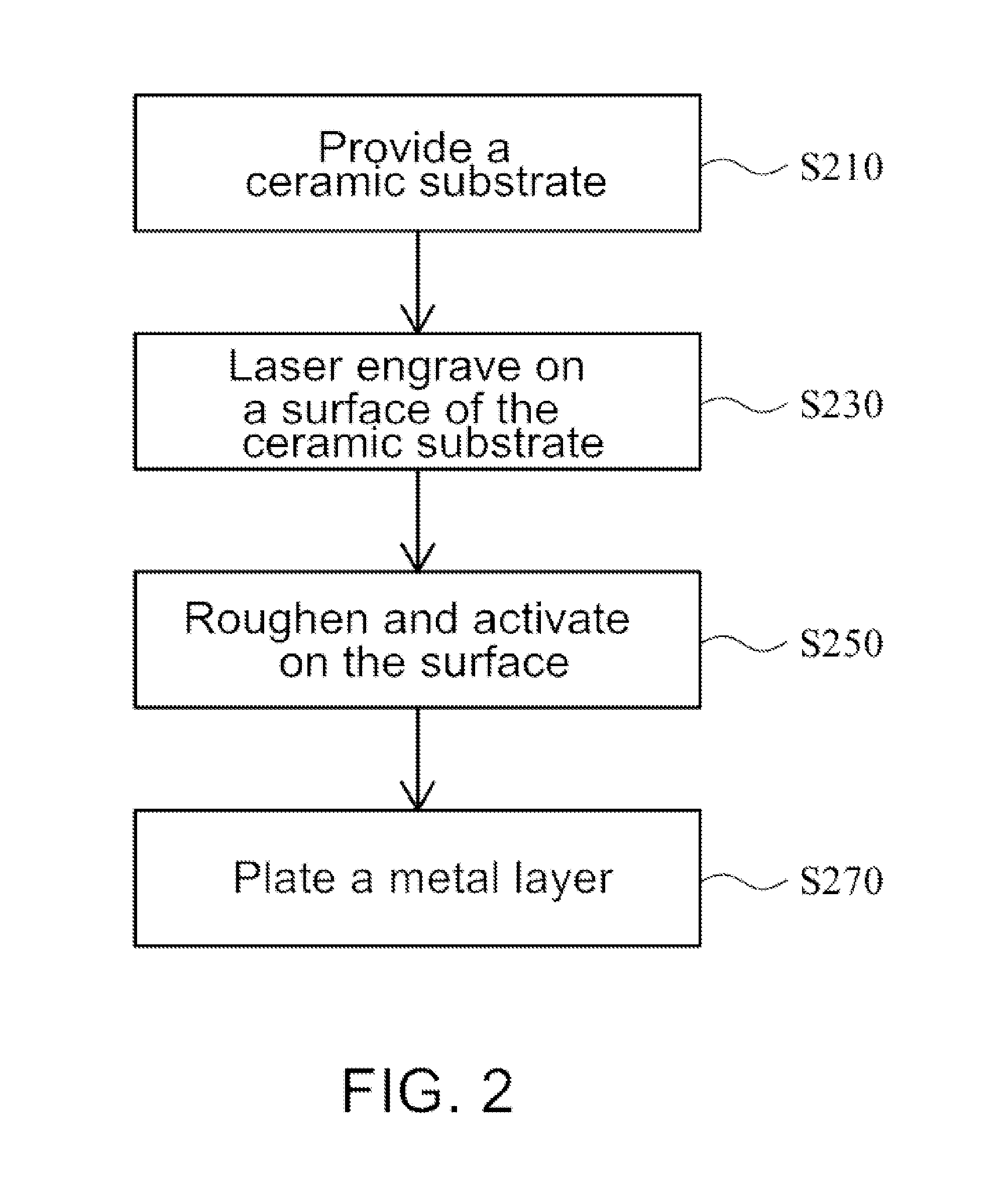

Ceramic circuit board of laser plate copper and manufacturing method thereof

InactiveUS20150208499A1Improve adhesionImprove plating quality3D rigid printed circuitsPrinted circuit aspectsLaser engravingHemt circuits

A ceramic circuit board of laser plate copper and manufacturing method thereof is provided. The method includes: providing a ceramic substrate; laser engraving, on a surface of the ceramic substrate, so as to form a circuit pattern of a plurality of groove structures; roughening and activating, on the surface of the ceramic substrate, by washing the surface of the ceramic substrate with a roughening and activating solution; and plating a metal layer, on the groove structures, so as to form a conductive loop defined by the circuit pattern.

Owner:RHEMA TECH & TRADING COMPANY

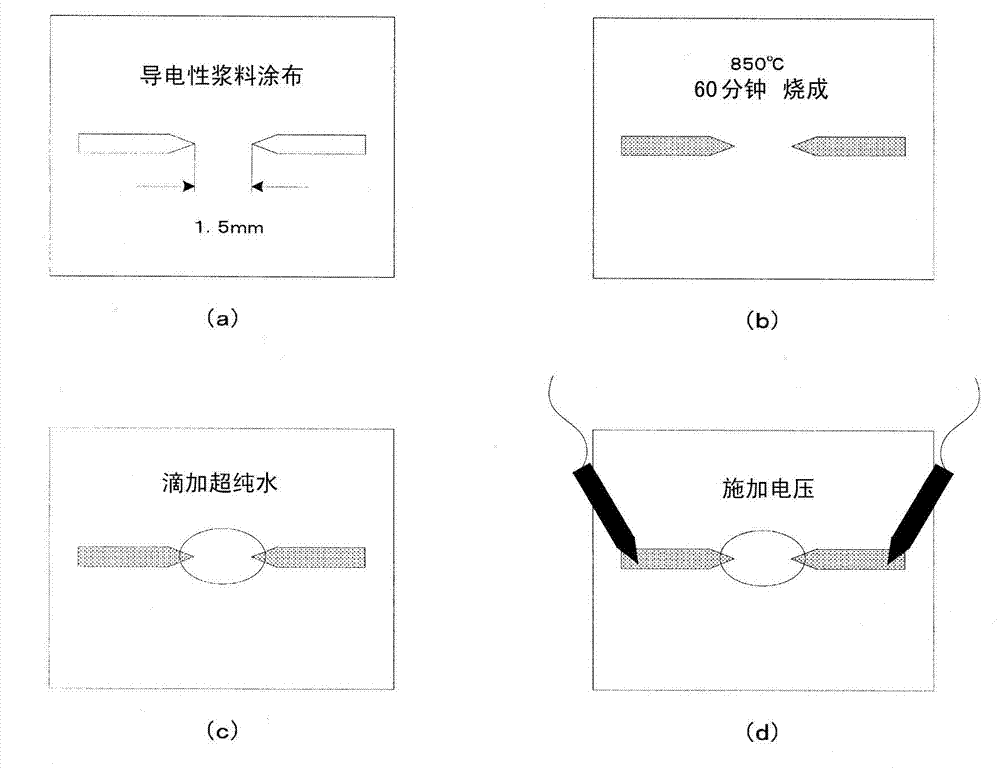

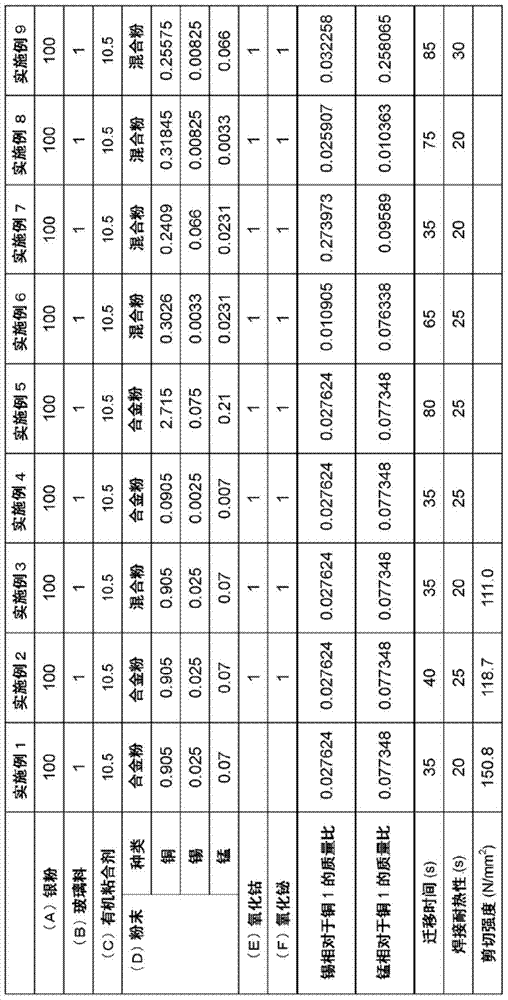

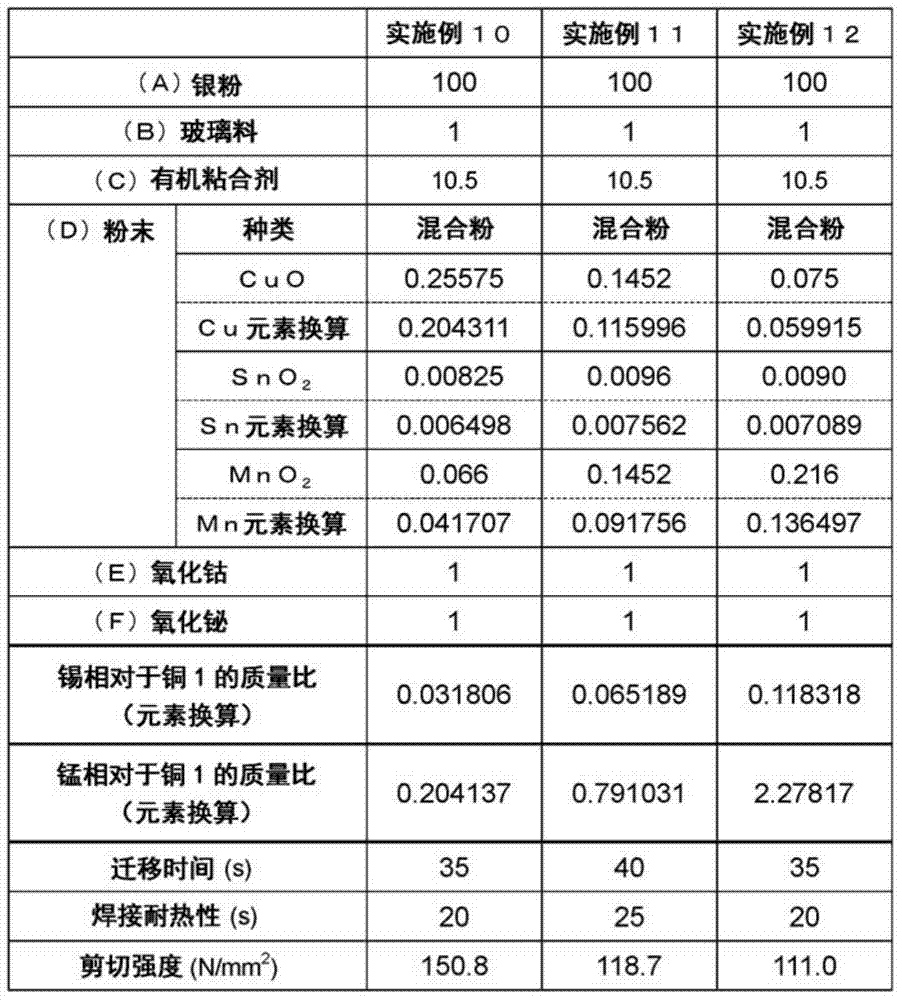

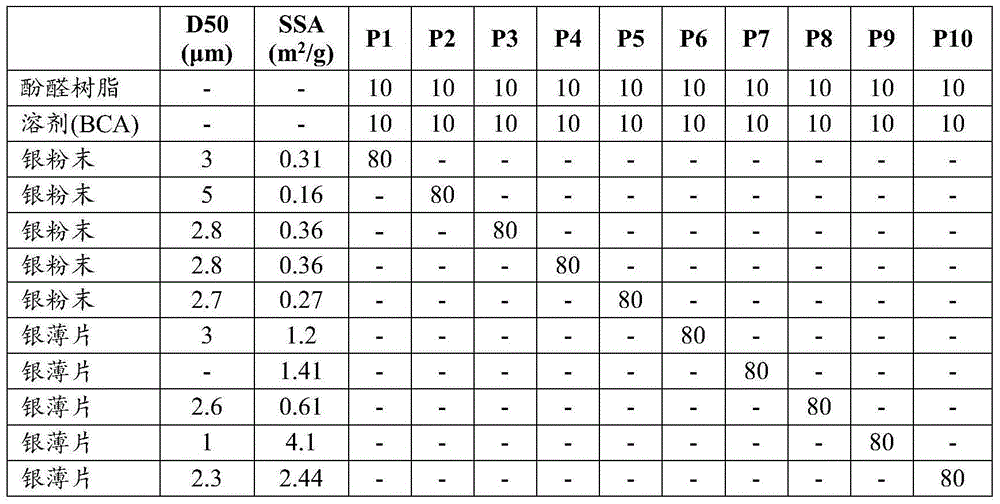

Electroconductive paste

InactiveCN104737238AExcellent electromigration resistanceExcellent soldering heat resistanceConductive layers on insulating-supportsPrinted circuit aspectsFritHeat resistance

Provided is a sintered-type electroconductive paste having excellent electromigration resistance, solder heat resistance, and adhesion to substrates. This electroconductive paste comprises: (A) silver powder; (B) glass frit; (C) an organic binder; and (D) a powder including copper, tin, and manganese. This electroconductive paste preferably comprises 0.1-5.0 parts by mass of said powder (D) per 100 parts by mass of said silver powder (A).

Owner:NAMICS CORPORATION

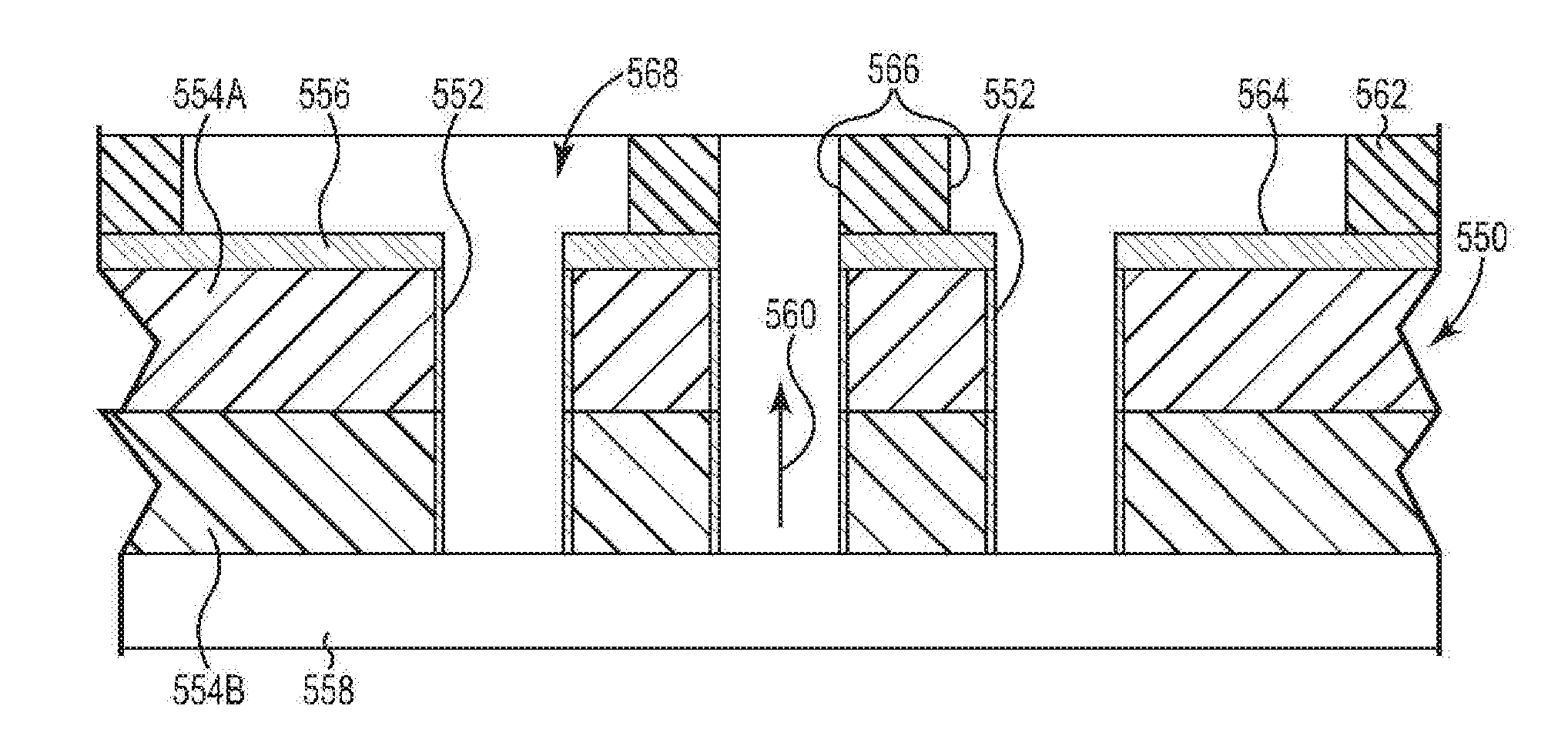

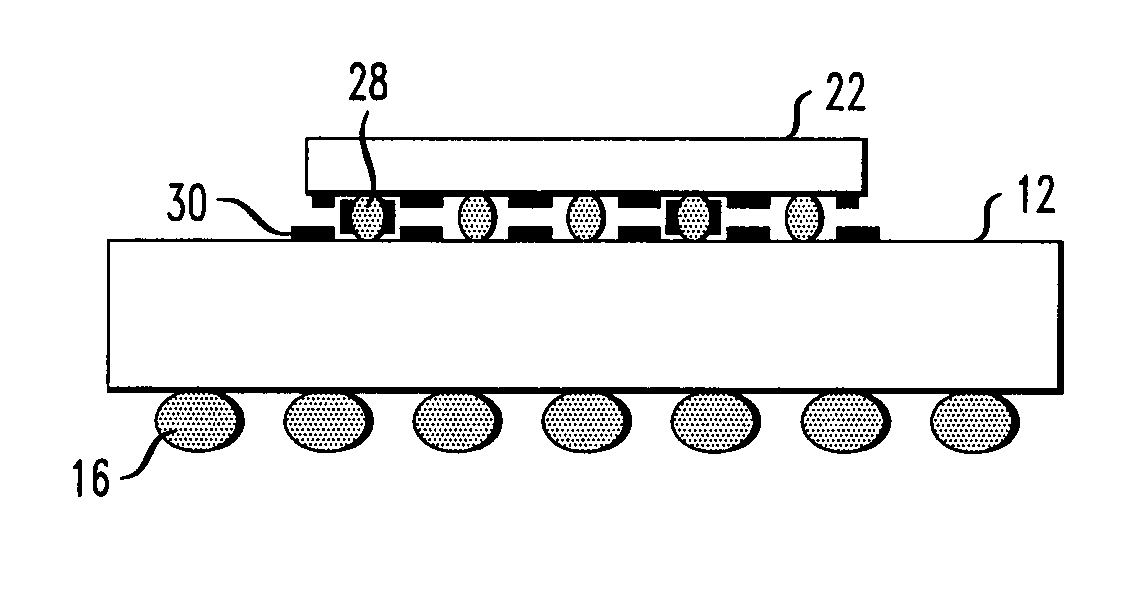

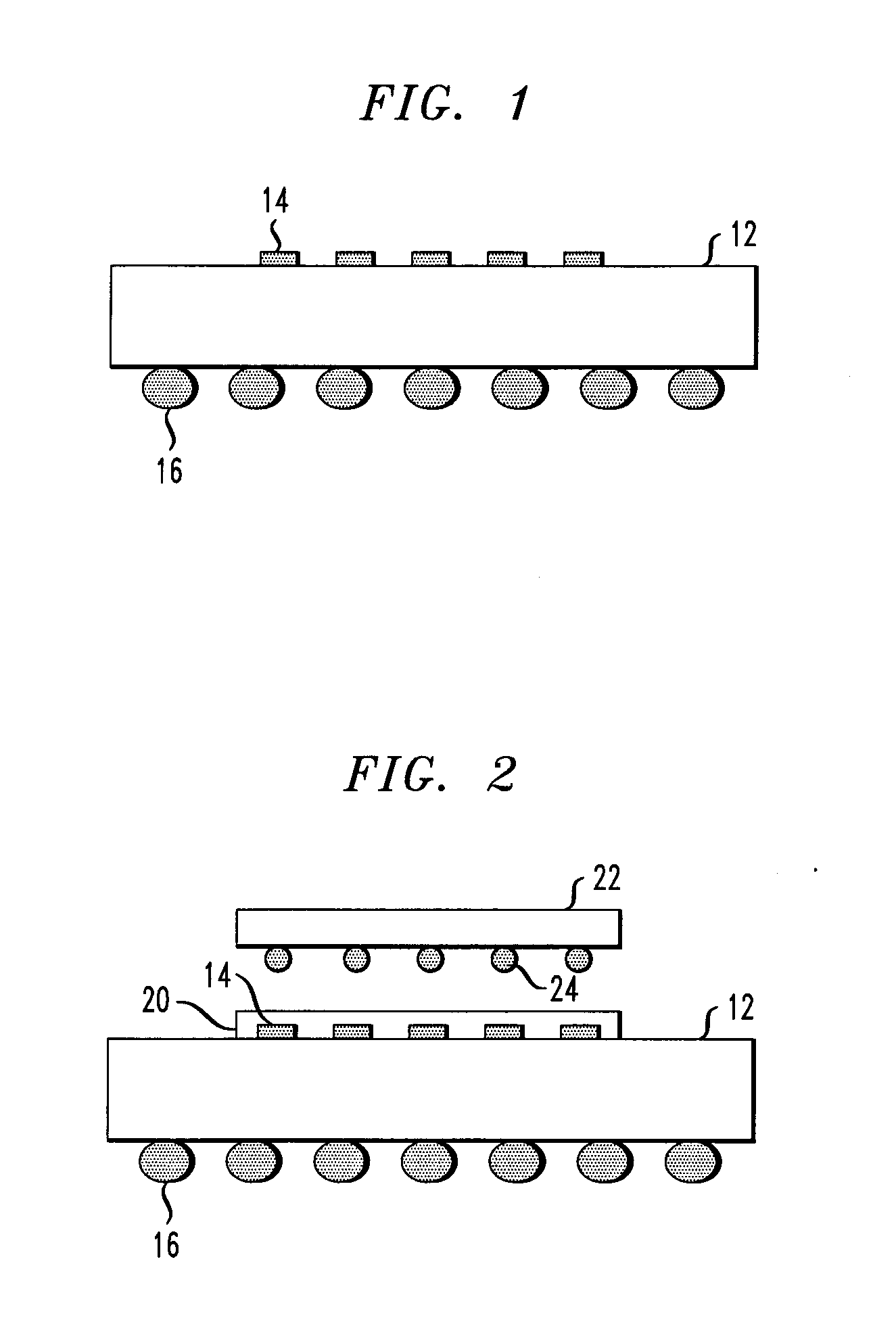

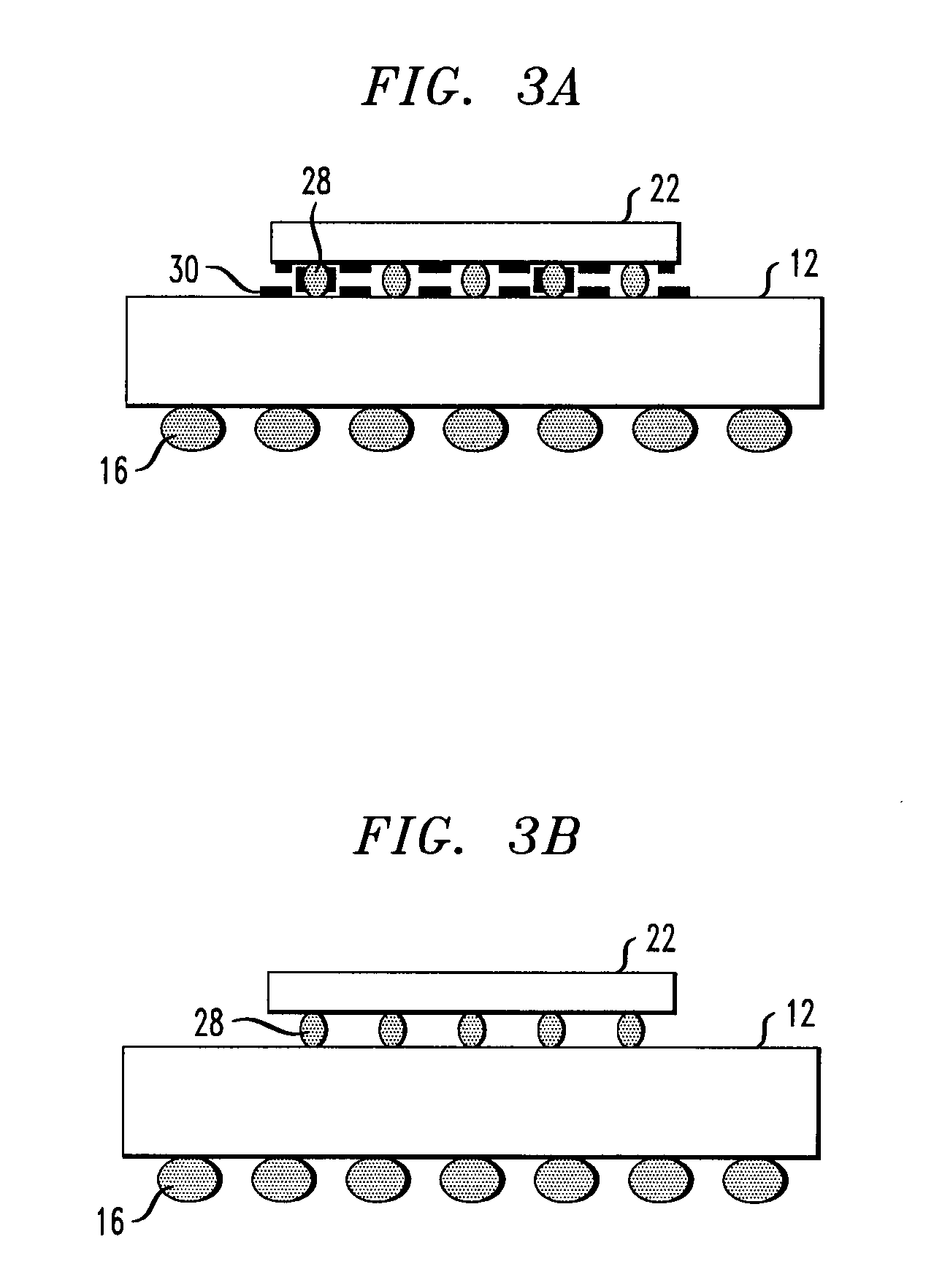

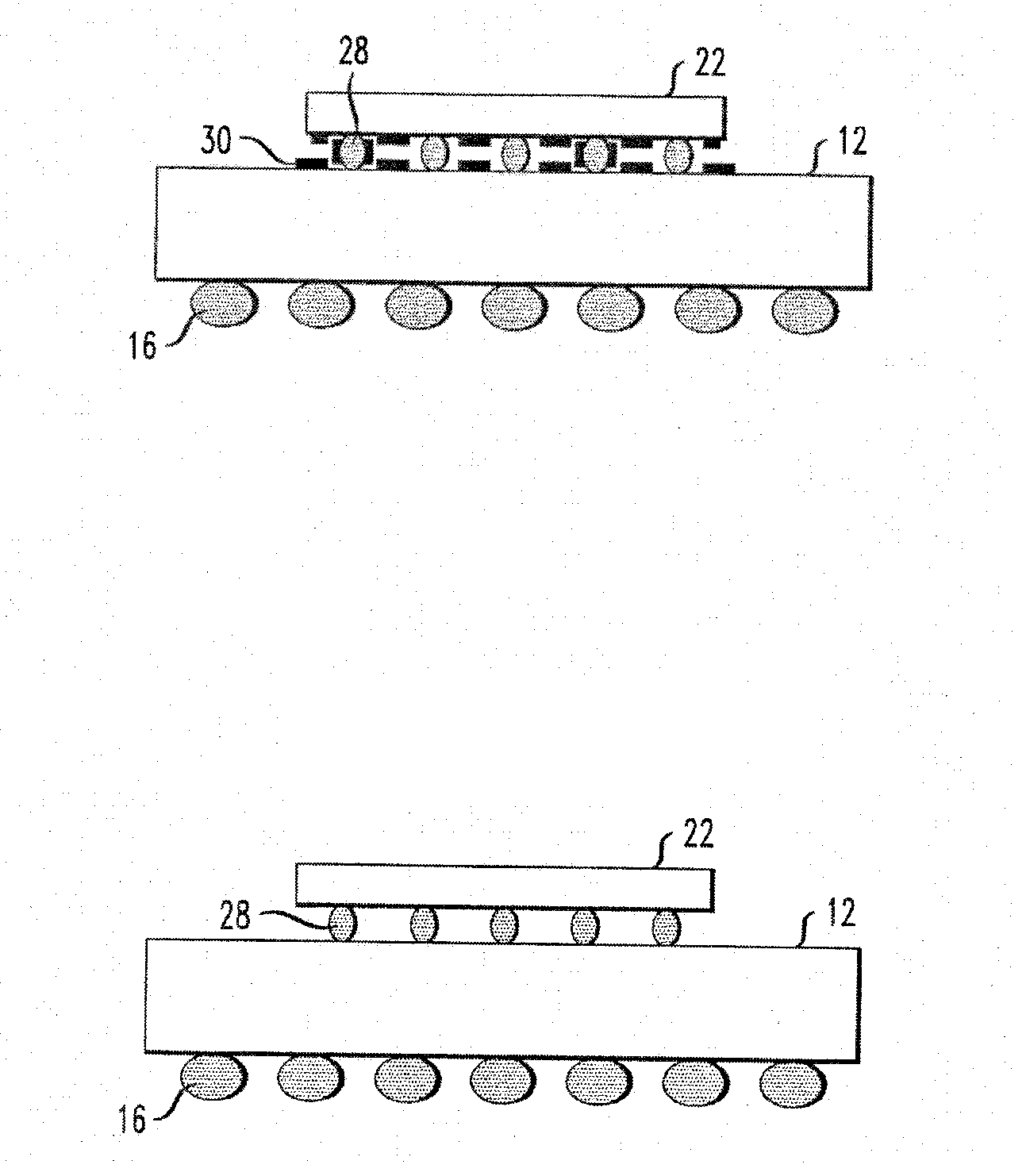

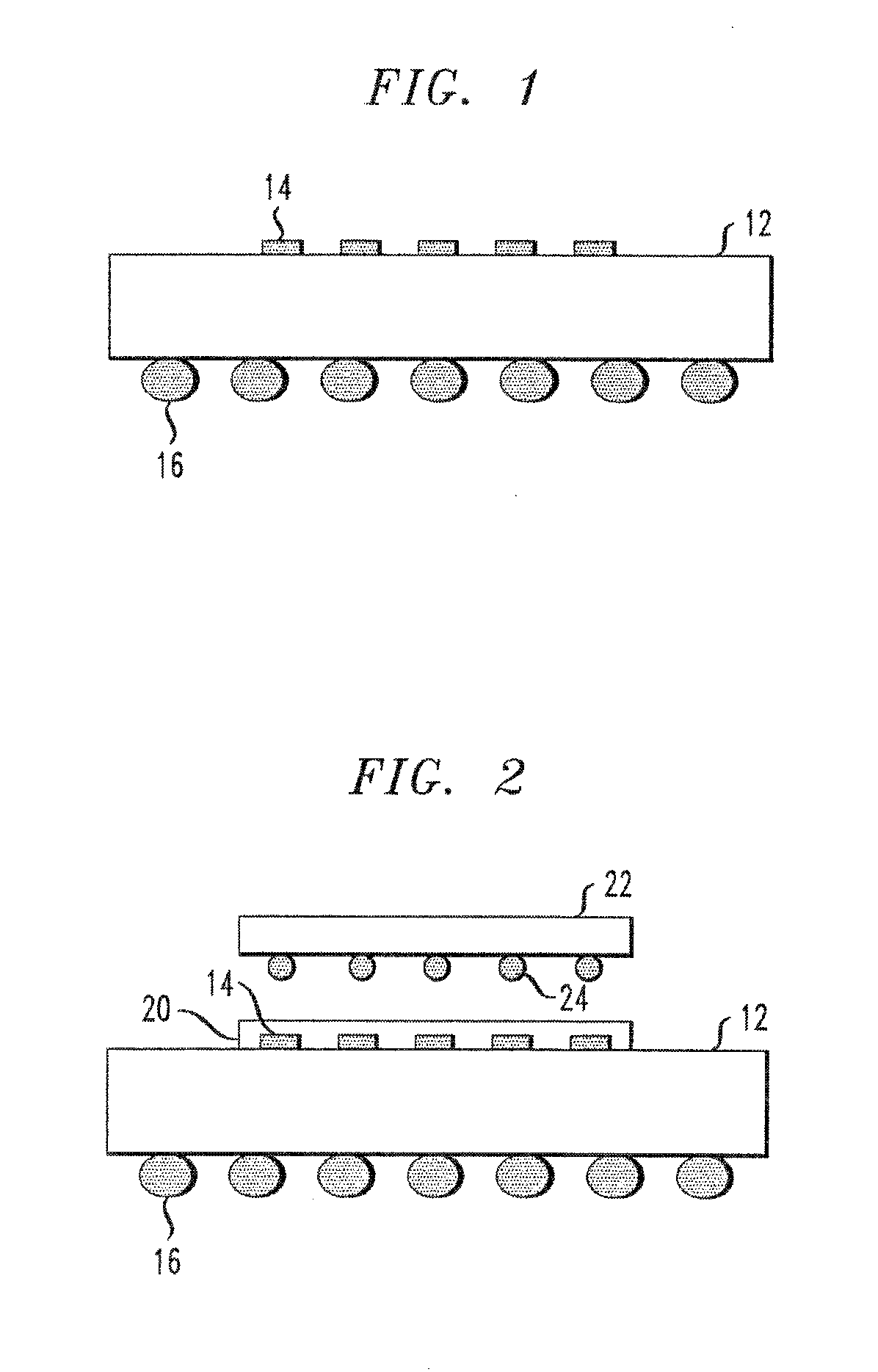

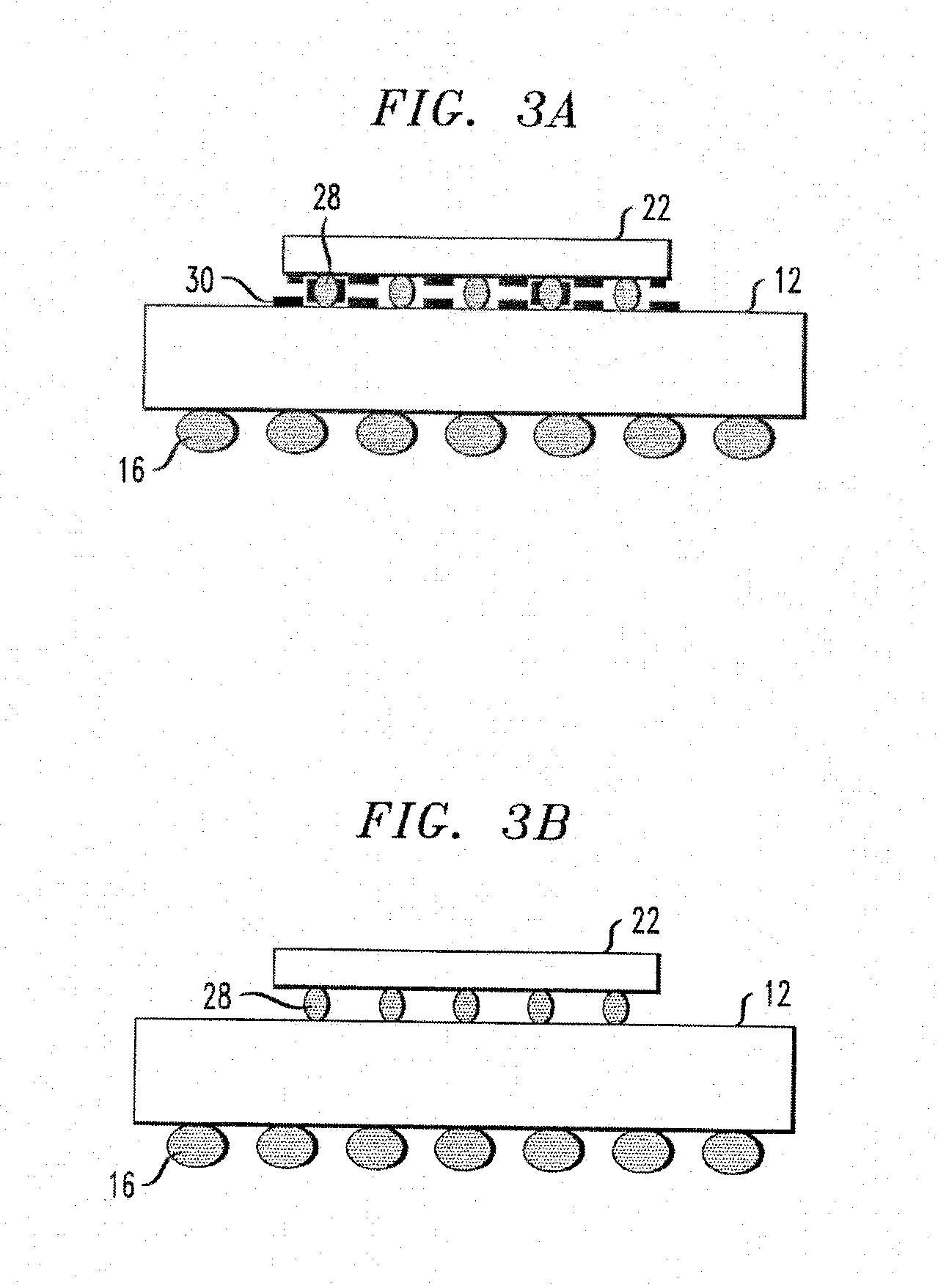

Fusion bonded liquid crystal polymer electrical circuit structure

ActiveUS20160212862A1Improve electrical performanceReduce linePrinted circuit aspectsSolid-state devicesResistConductive materials

A method of making a fusion bonded circuit structure. A substrate is provided with a seed layer of a conductive material. A first resist layer is deposited on the seed layer. The first resist layer is processed to create first recesses corresponding to a desired first circuitry layer. The first recesses expose, portions of the seed layer of conductive material. The substrate is electroplated to create first conductive traces defined by the first recesses. The first resist layer is removed to reveal the first conductive traces. The substrate is etched to remove exposed portions of the seed layer adjacent the first conductive traces. A portion of the seed layer is interposed between the first conductive traces and the substrate. A first layer of LCP is fusion boned to the first major surface of the substrate to encapsulate the first conductive traces in an LCP material. The first LCP layer can be laser drilled to expose the conductive traces.

Owner:LCP MEDICAL TECH LLC

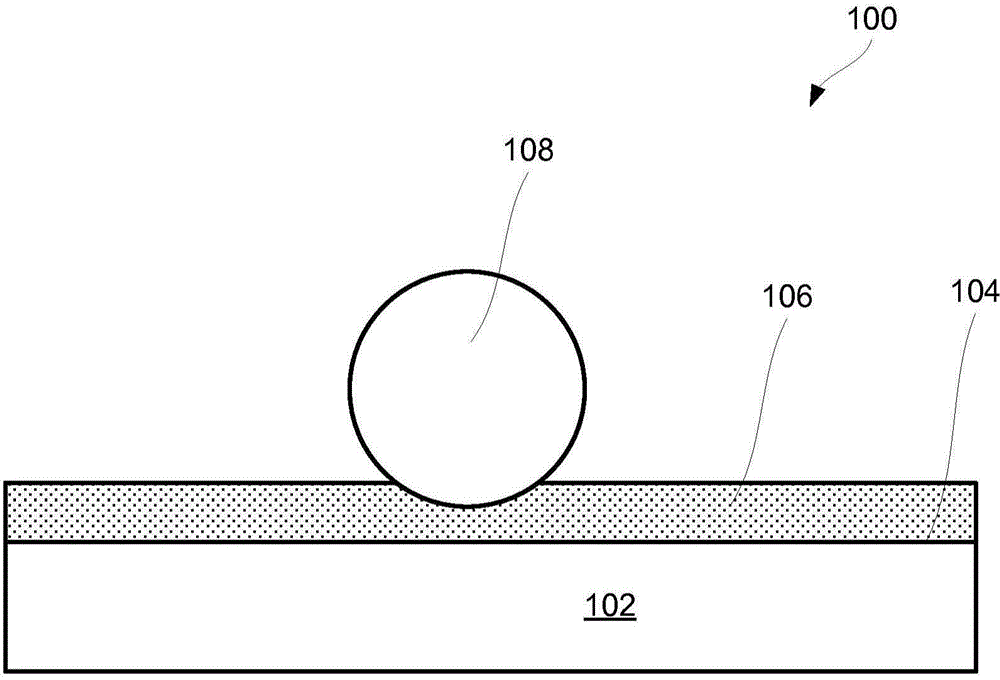

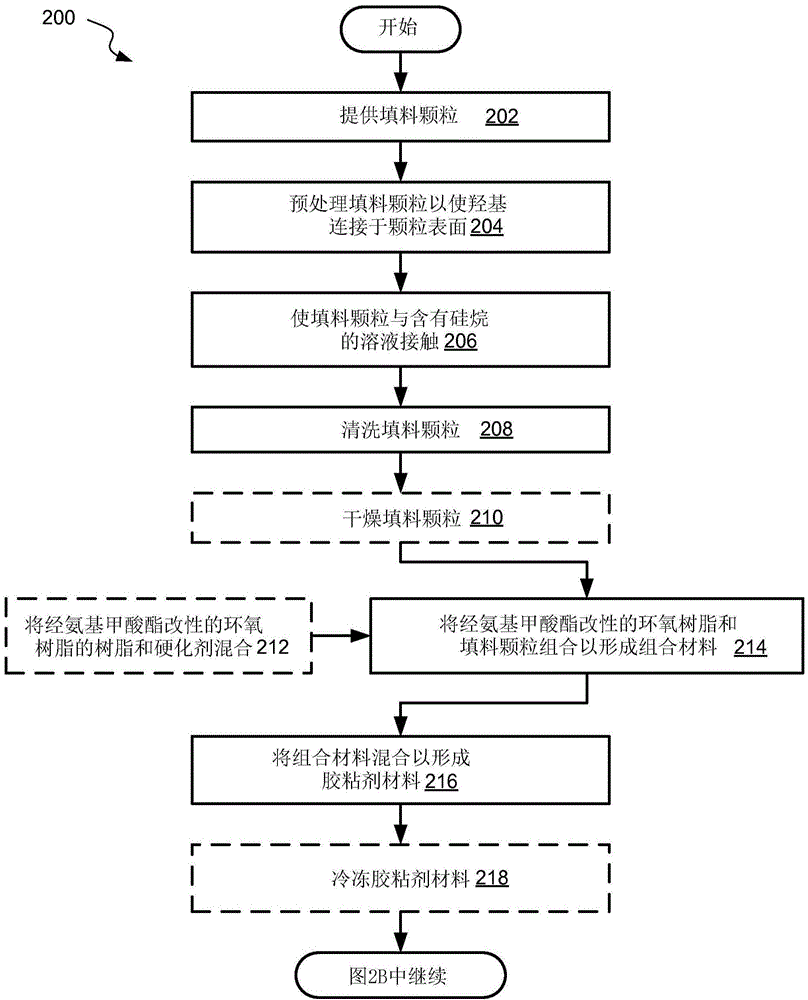

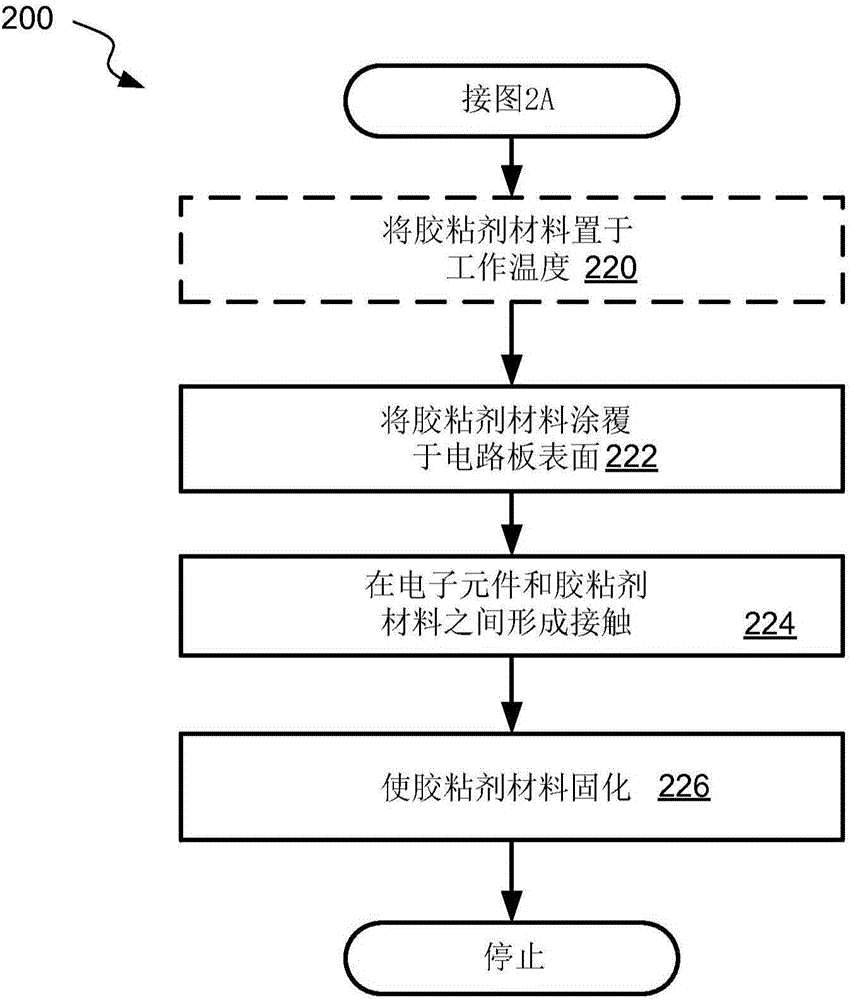

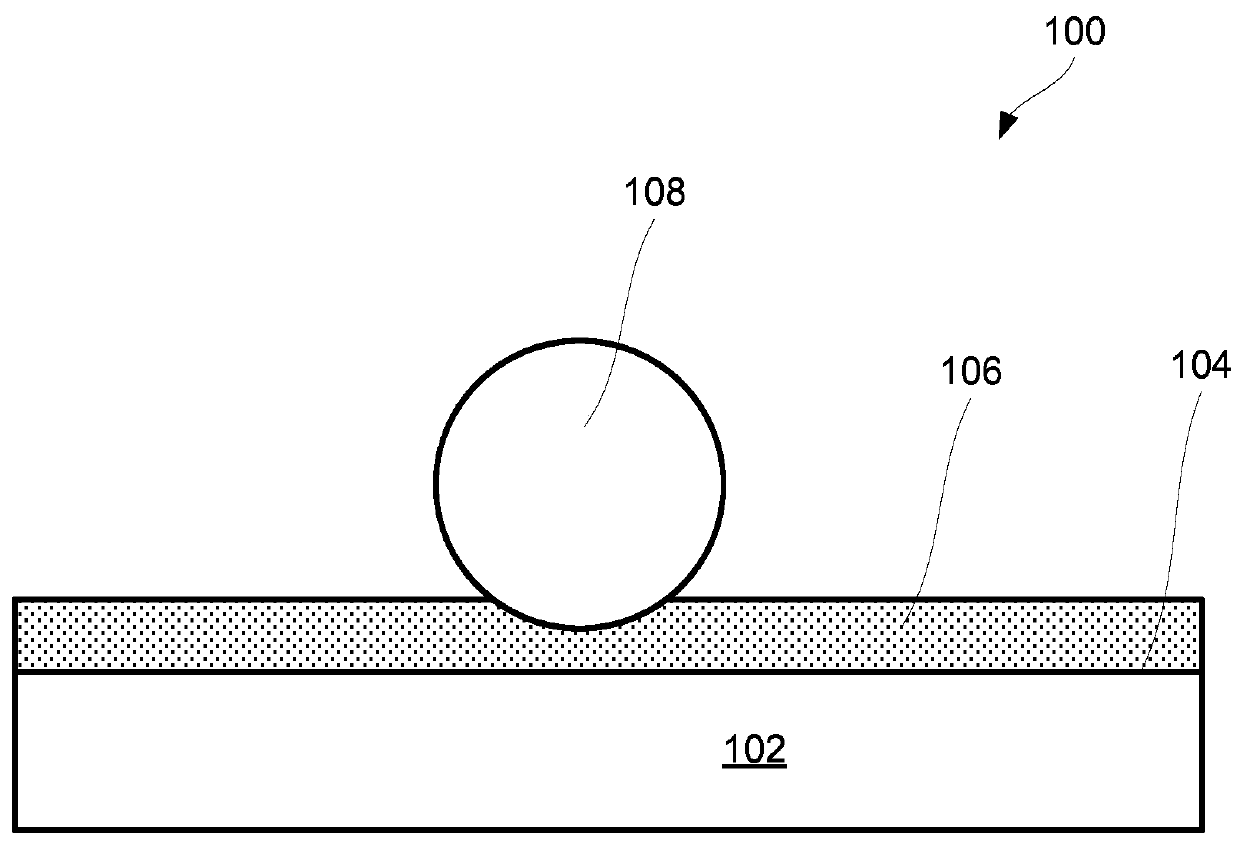

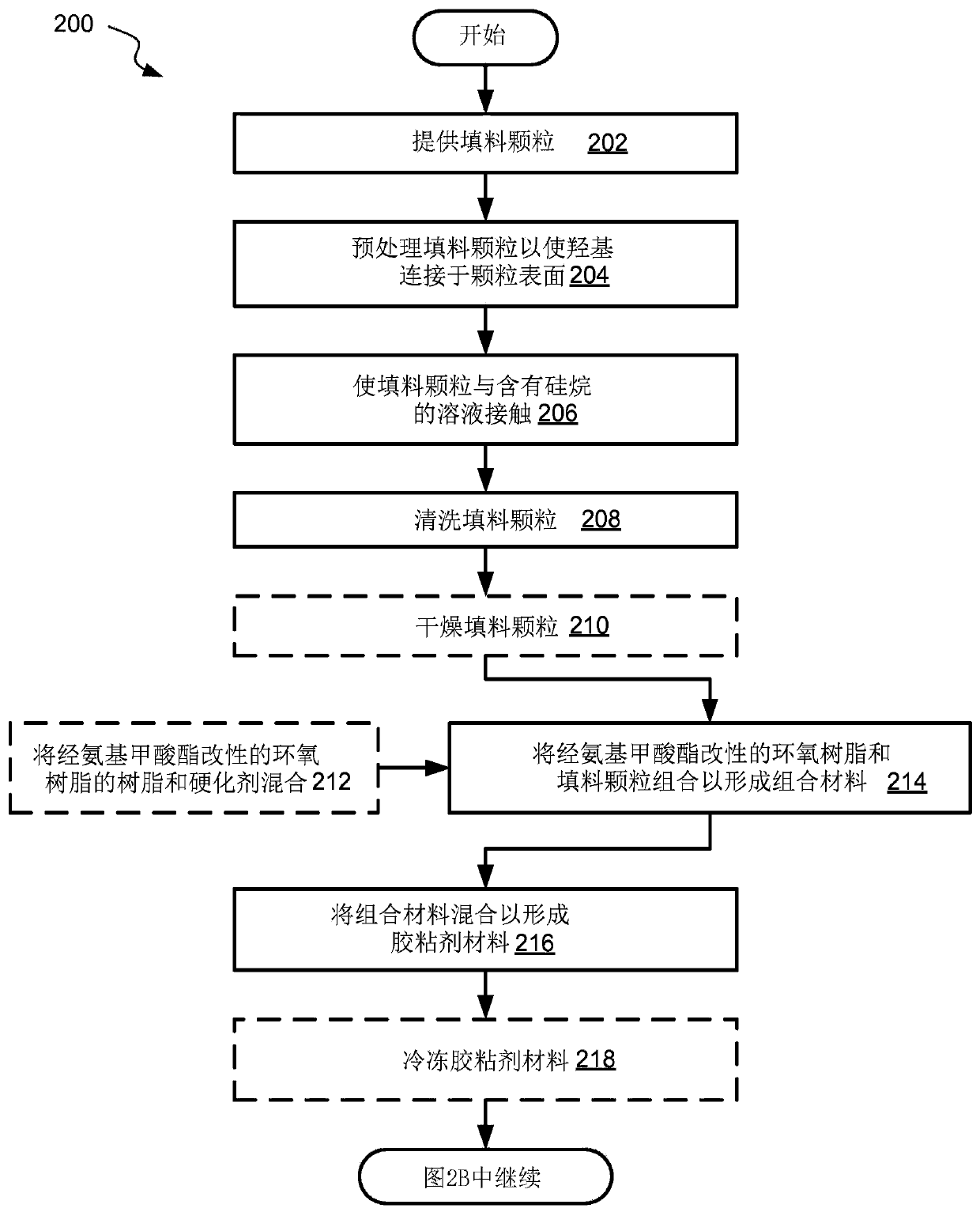

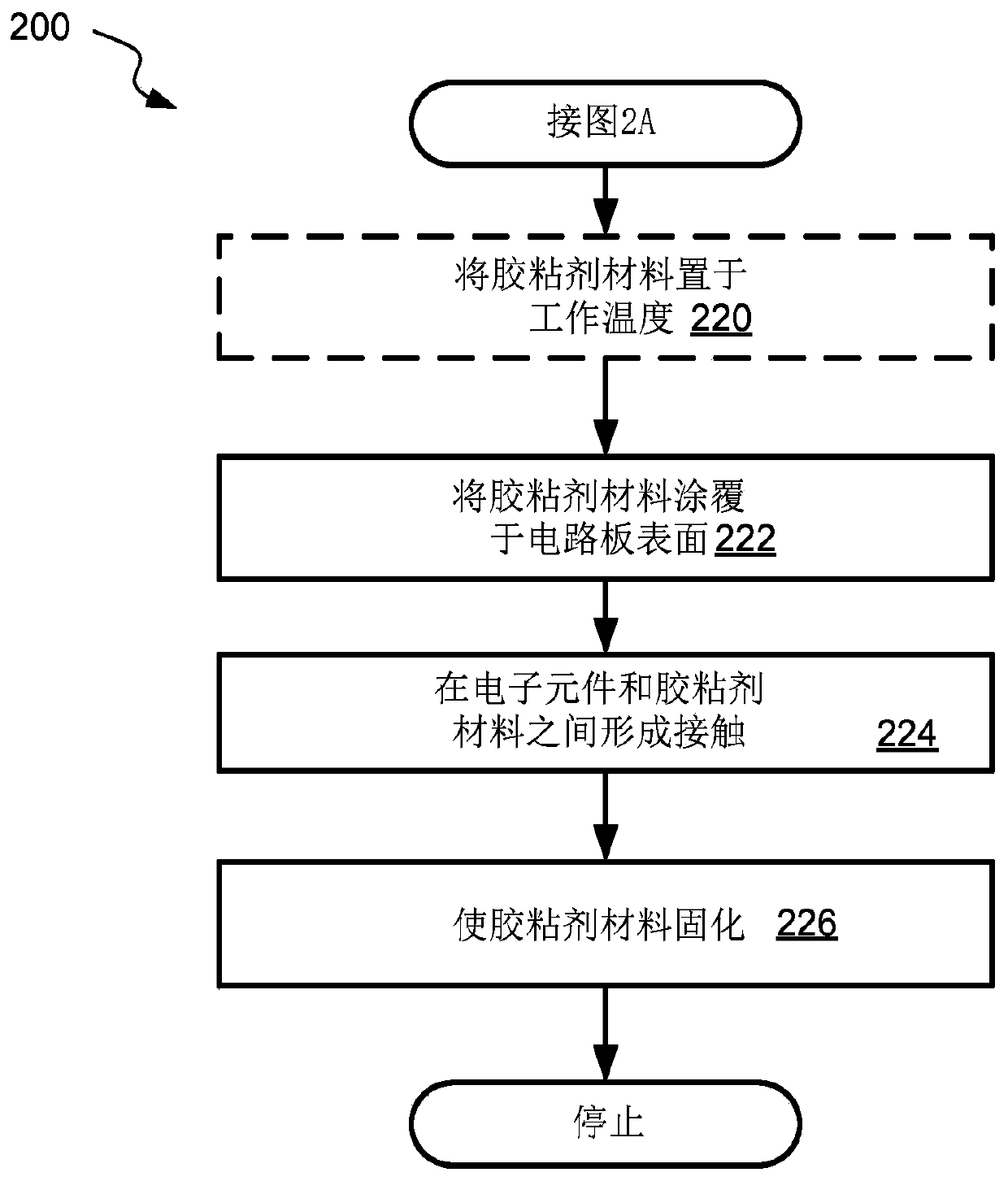

Thermally conductive flexible adhesive material for aerospace applications

Provided are methods of forming thermally conductive flexible bonds for use in electronic boards of unmanned spacecrafts and other types of aircraft. Also provided are methods of preparing adhesive materials to form these bonds including methods of preparing treated filler particles. In some aspects, an adhesive material includes filler particles having organofunctional groups, such as boron nitride particles treated in silane. These particles may be combined with a urethane modified epoxy to form the adhesive material. The weight ratio of the particles in the adhesive material may be about 40-60%. The adhesive material may be thermally cured using a temperature of less than 110°C to prevent damage to bonded electronic components. The cured adhesive may have a thermal conductivity of at least about 2 W / m K measured in vacuum and may have a glass transition temperature if less than -40°C.

Owner:THE BOEING CO

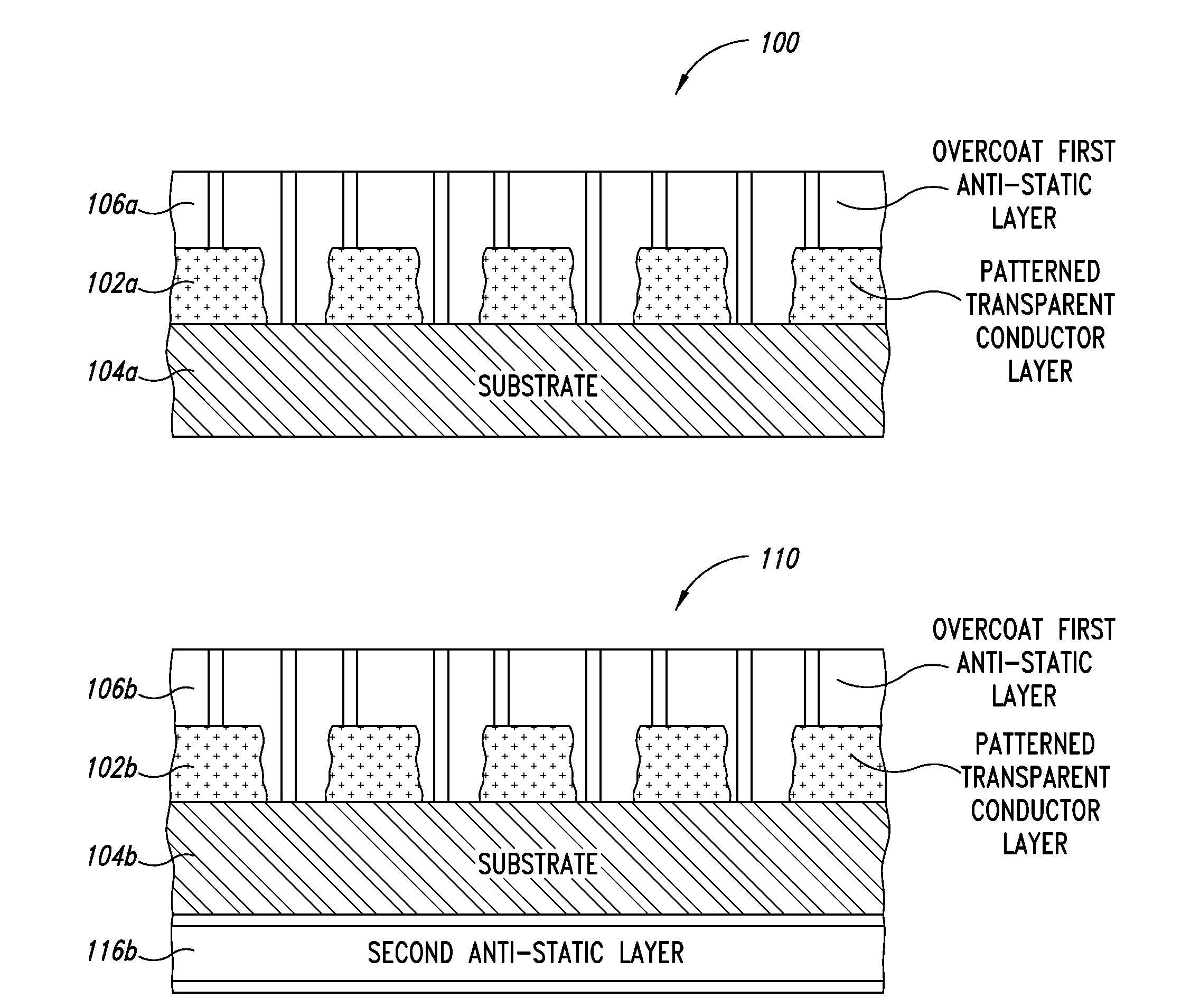

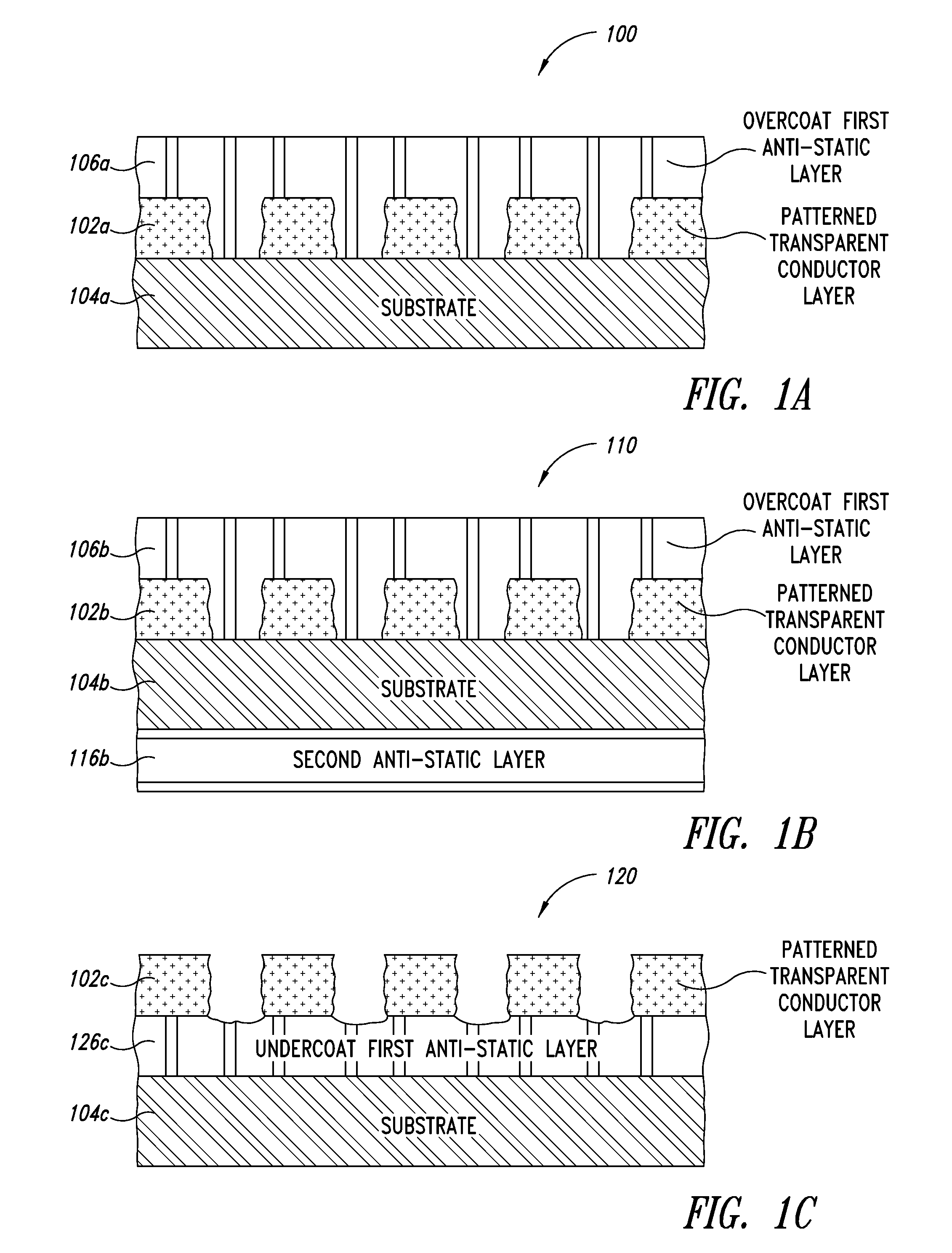

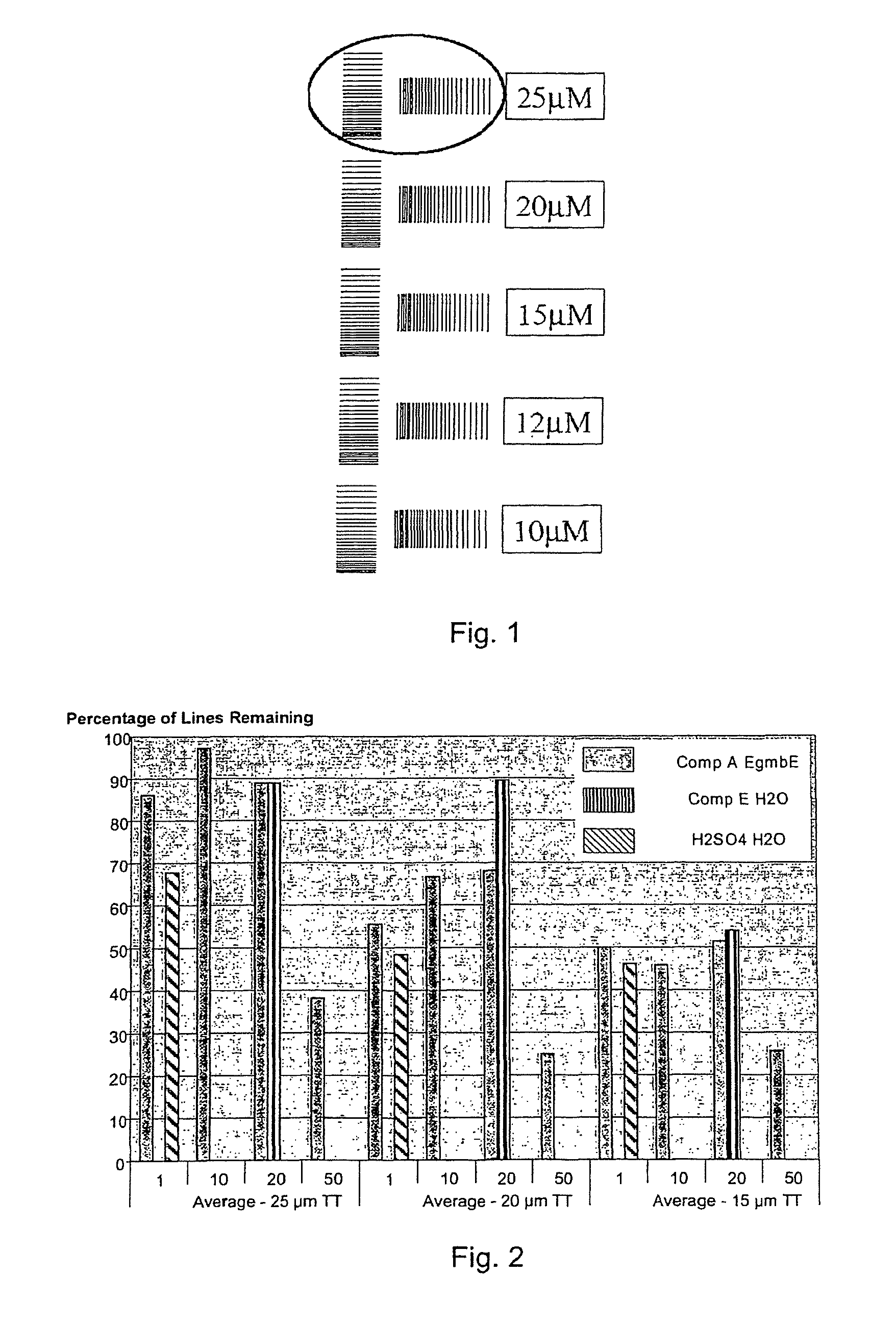

Conductive nanostructure-based films with improved ESD performance

ActiveUS20140340811A1Avoid damageReduce accumulationNanoinformaticsPrinted circuit dielectricsElectrical conductorEngineering

Optical stacks containing one or more patterned transparent conductor layers may be damaged by electrostatic discharges that occur during the optical stack manufacturing process. Such damage may result in non-conductive conductors within the patterned transparent conductor layer. An electrostatic discharge protected optical stack may include a substrate layer, a first anti-static layer having a sheet resistance of from about 106 ohms per square (Ω / sq) to about 109 Ω / sq, and a patterned transparent conductor layer. Methods of testing and assessing damage to patterned transparent conductors are provided.

Owner:CHAMP GREAT INTL

Flux Composition and Techniques for Use Thereof

The present invention is directed to flux compositions and uses thereof. One composition comprises an activator and a solvent being a glycerol ethoxylate with a molecular weight of 200-500. Another composition comprises an activator, a solvent being a glycerol ethoxylate with a molecular weight of 200-500 and an amine. A soldering method for joining objects is also provided, comprising the steps of applying a flux composition to at least a portion of one or more of the objects, and joining the objects.

Owner:IBM CORP

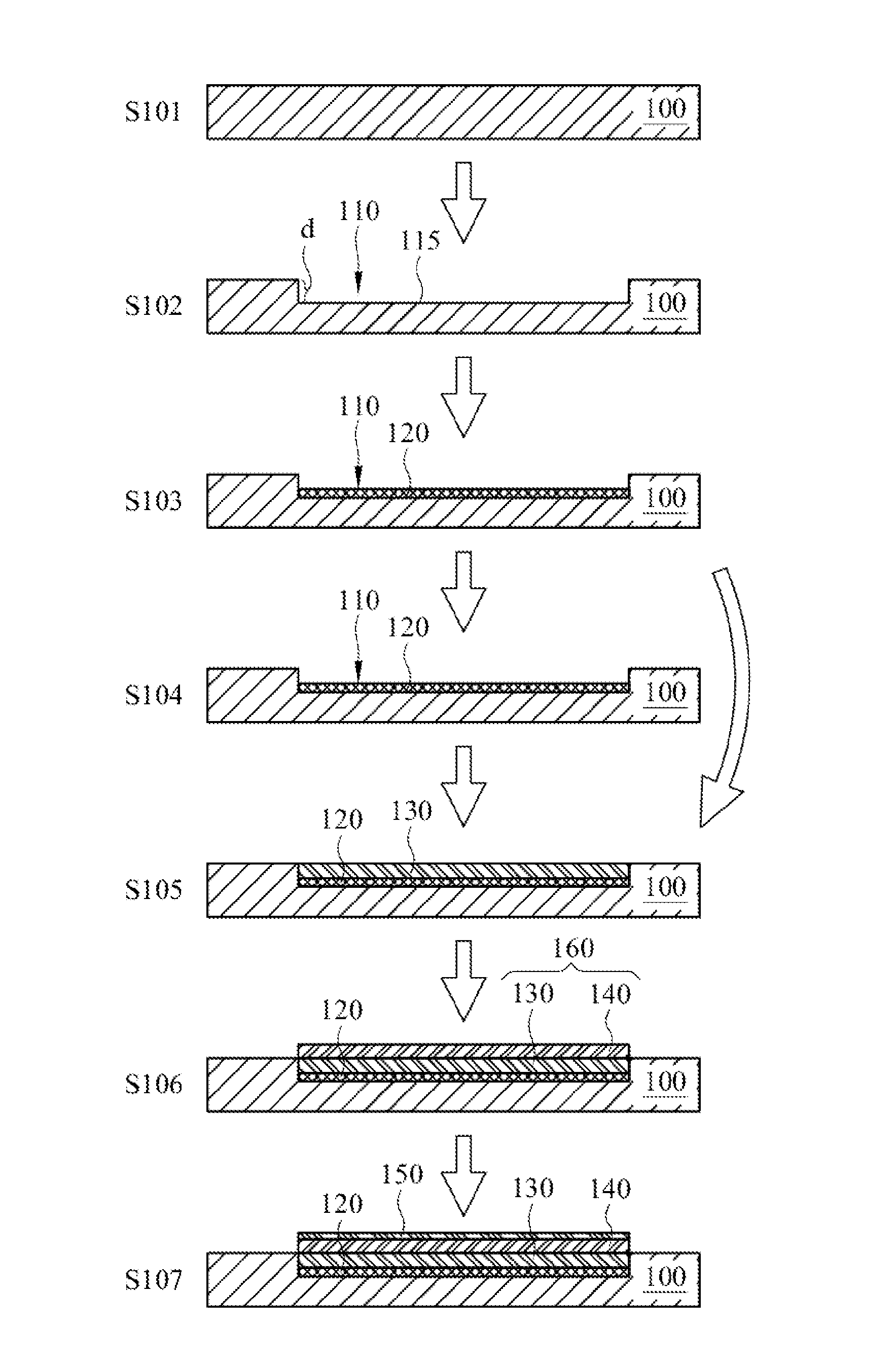

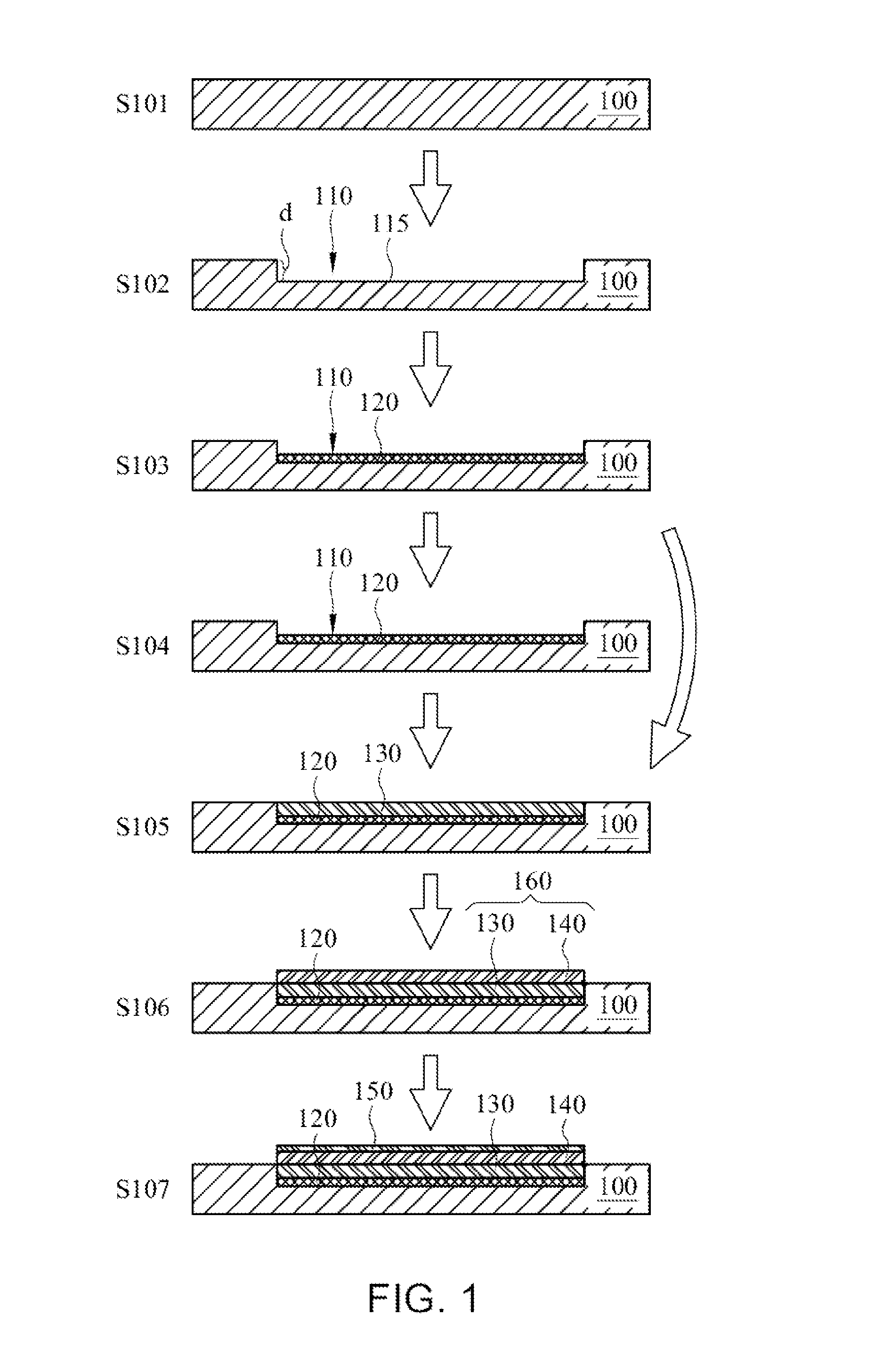

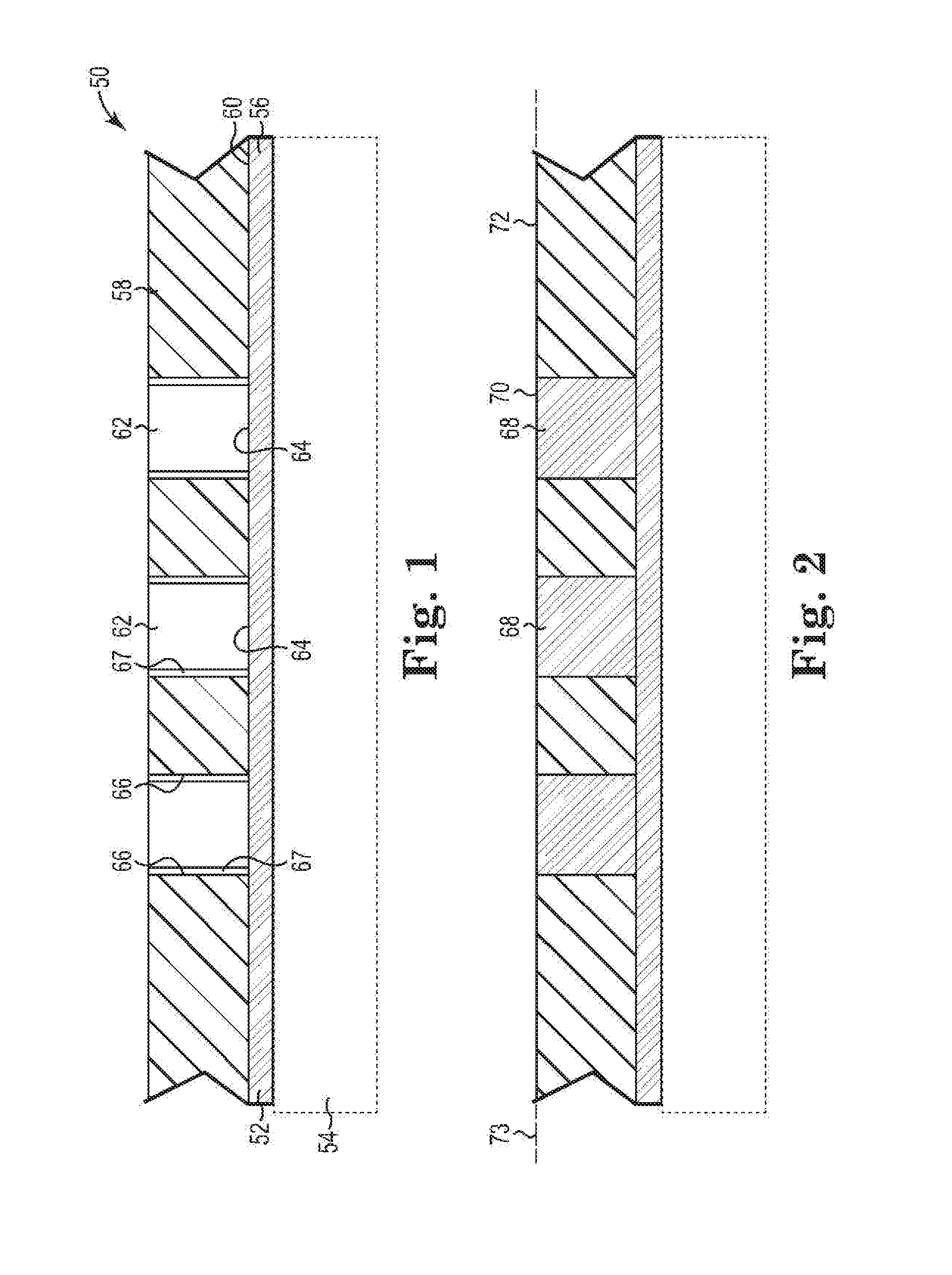

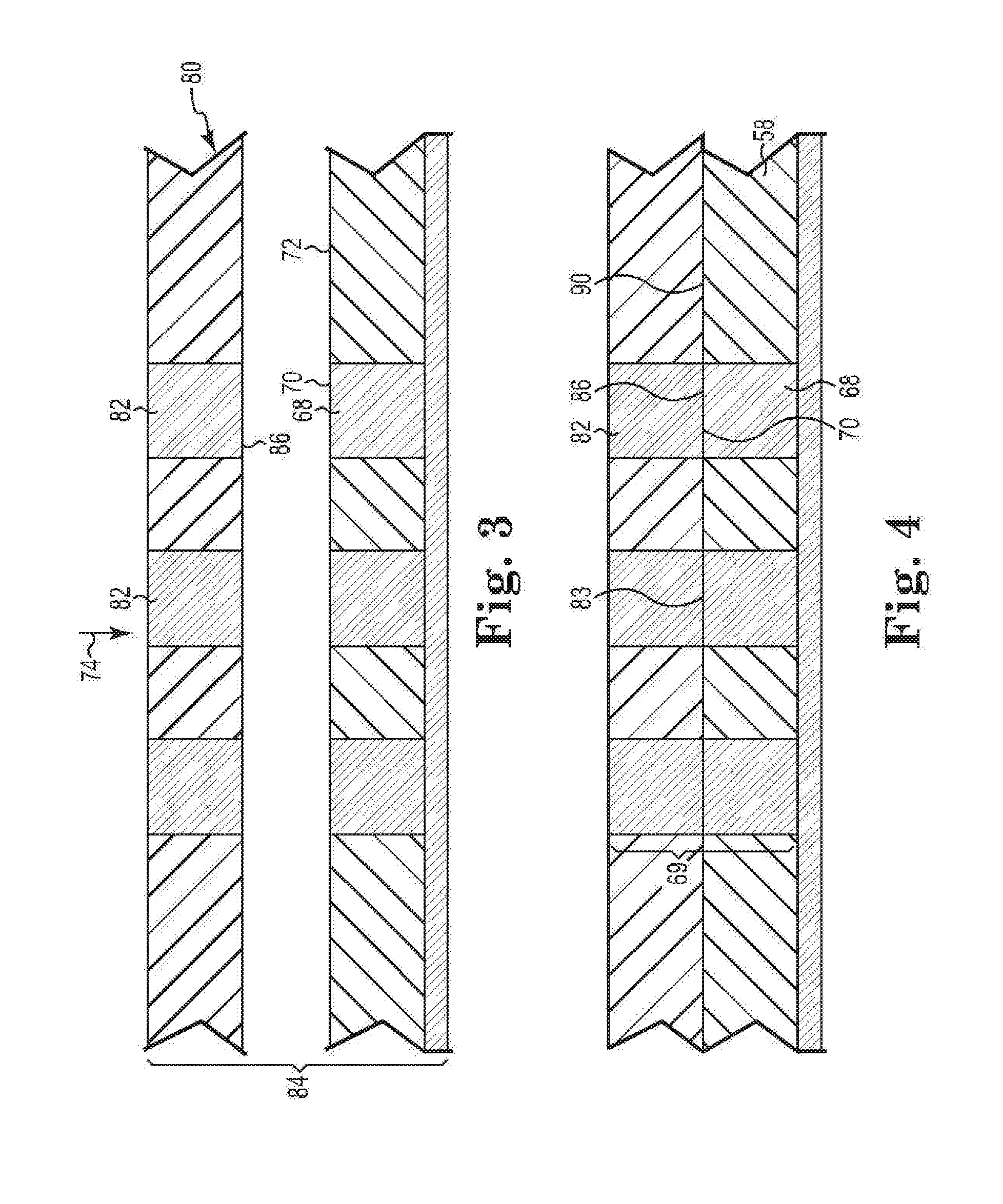

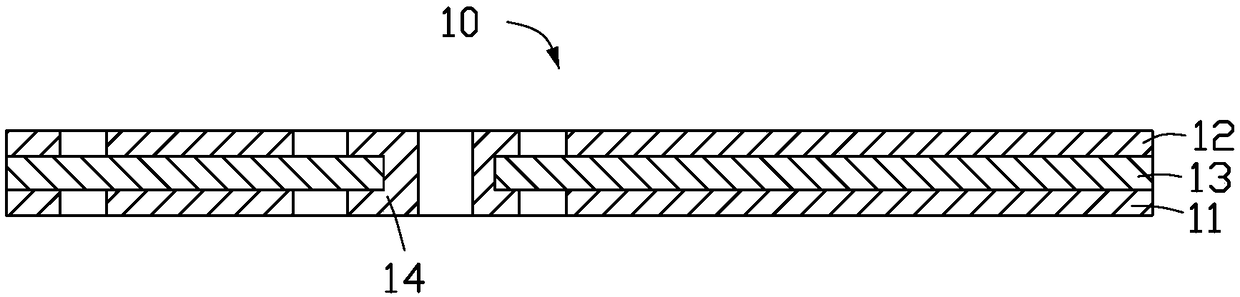

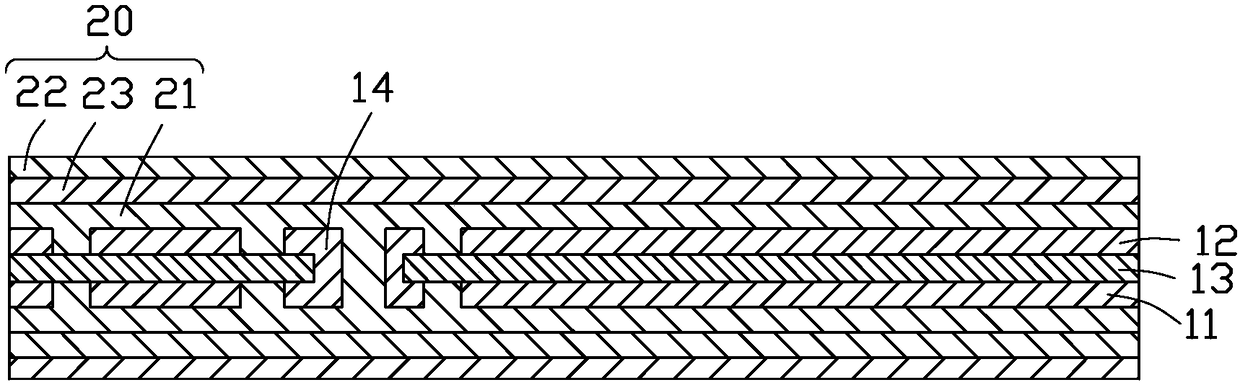

Rigid-flexible printed circuit board and manufacturing method thereof

InactiveCN109429441ASavings in lamination processReduce thicknessSpecific circuit substancesMultilayer circuit manufactureAdhesivePrinted circuit board

The invention relates to a rigid-flexible printed circuit board. The rigid-flexible printed circuit board comprises a flexible printed circuit board, wherein the flexible printed circuit board comprises a flexible printed circuit board base material and a first conductive circuit layer formed on at least one surface of the flexible printed circuit board base material, a double-sided adhesive filmformed on the surface of the first conductive circuit layer, a dielectric layer formed on the double-sided adhesive film, an outer layer conductive circuit layer formed on the surface of the dielectric layer, and a conductive hole, wherein the double-sided adhesive film comprises an insulating layer, and a first bonding layer and a second bonding layer, wherein the first bonding layer and the second bonding layer are formed on the two opposite surfaces of the insulating layer; the first bonding layer is in contact with the first conductive circuit layer; the dielectric layer comprises a firstopening, wherein the first opening exposes a part of the second bonding layer to form a flexible printed circuit board region; the conductive hole penetrates through the outer layer conductive circuitlayer to the first conductive circuit layer; and the outer layer conductive circuit layer is electrically connected with the first conductive circuit layer through the conductive hole.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

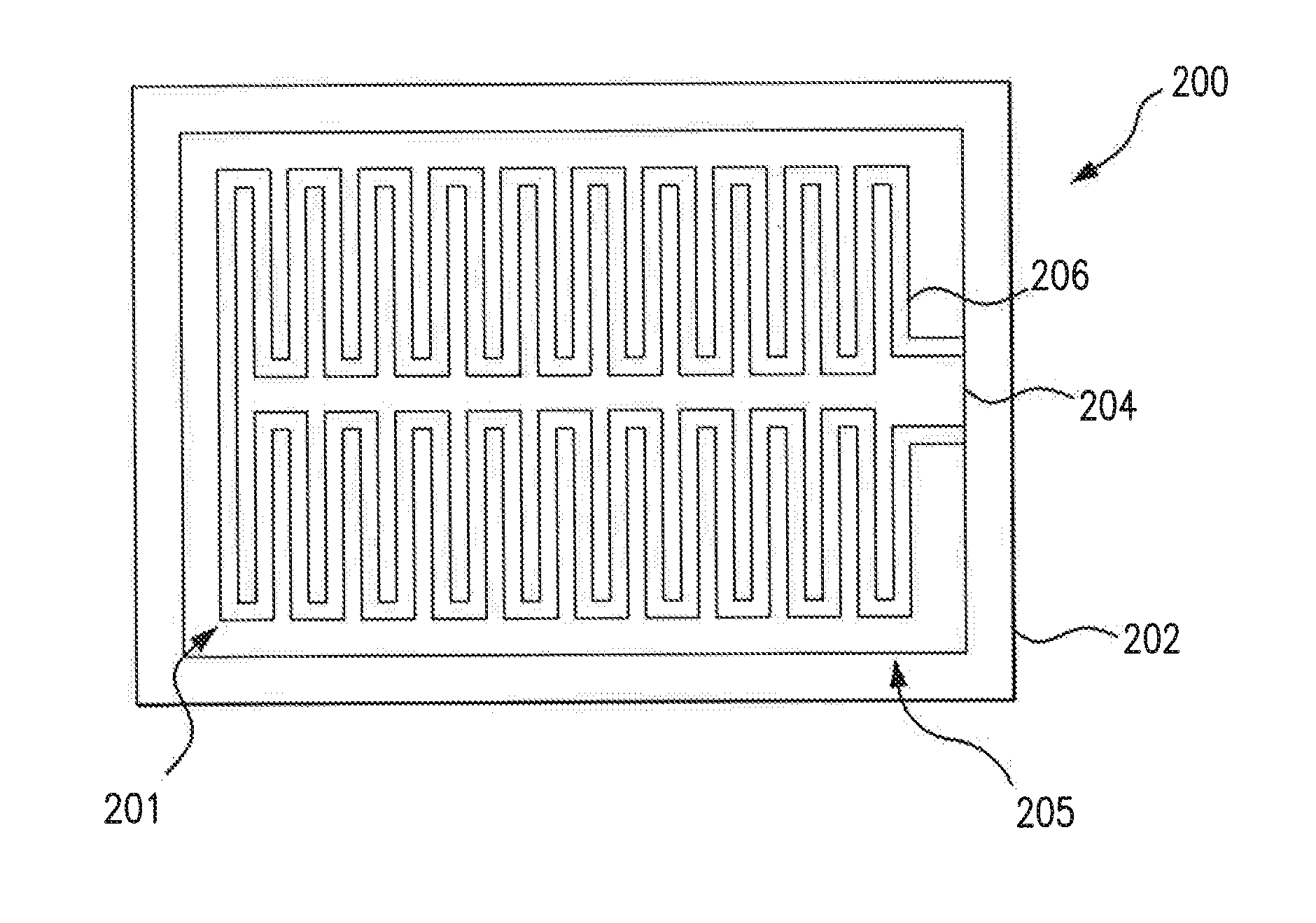

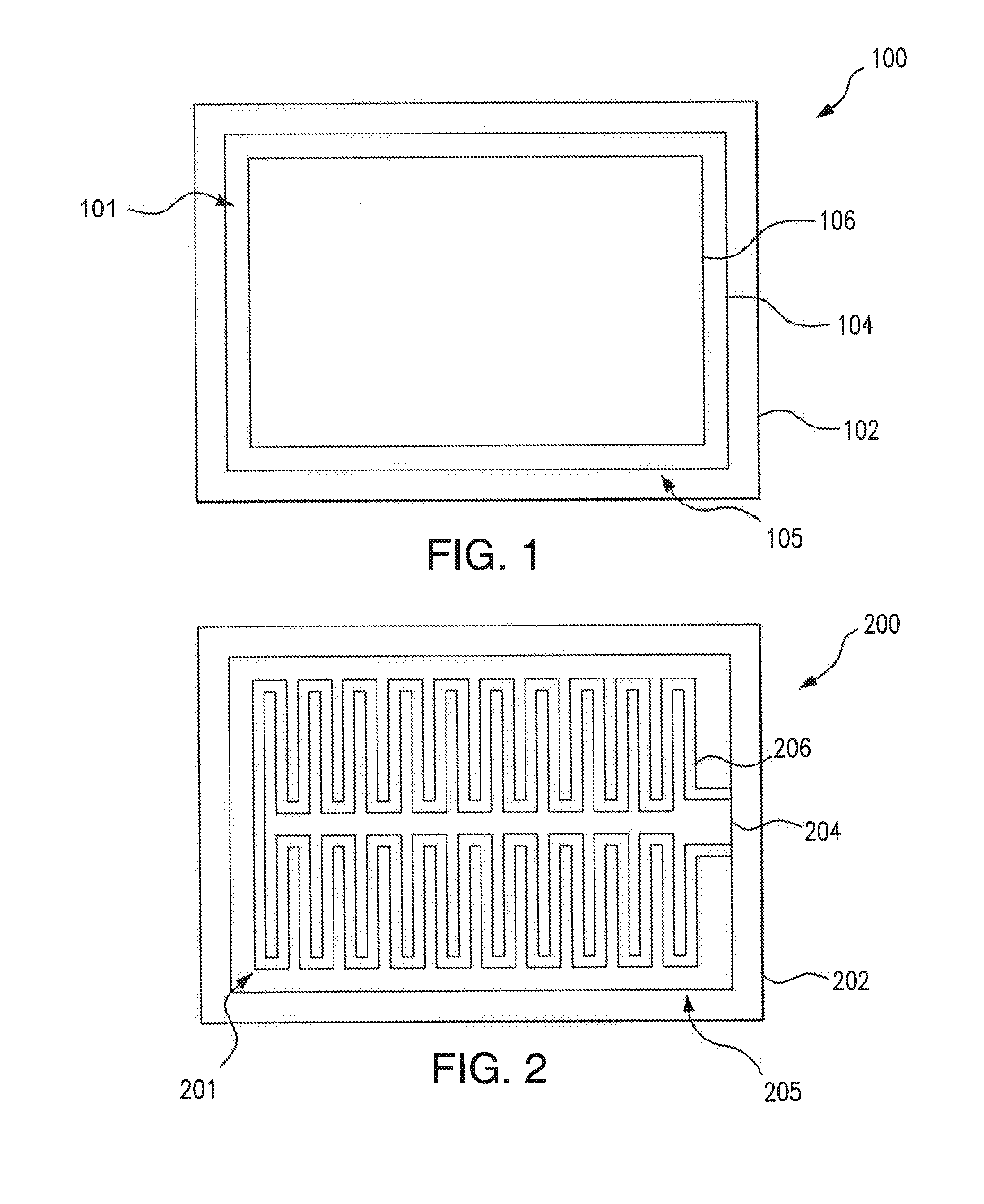

Heating elements for aircraft heated floor panels

A method of forming a heating element includes depositing a conductive ink of silver particles in an epoxy resin on a dielectric film to create a conductive circuit, and heat curing the conductive circuit to achieve a resistivity of the heating element less than 1.68×10−6 ohm·meter. An aircraft heated floor panel includes at least one floor panel of an aircraft includes a conductive circuit positioned within the floor panel having a conductive ink of silver particles in an epoxy resin on a dielectric film.

Owner:THE BF GOODRICH CO

Conductive paste

ActiveUS20150299477A1Improve adhesionIncrease resistanceConductive materialNon-conductive material with dispersed conductive materialConductive pasteFrit

Owner:NAMICS CORPORATION

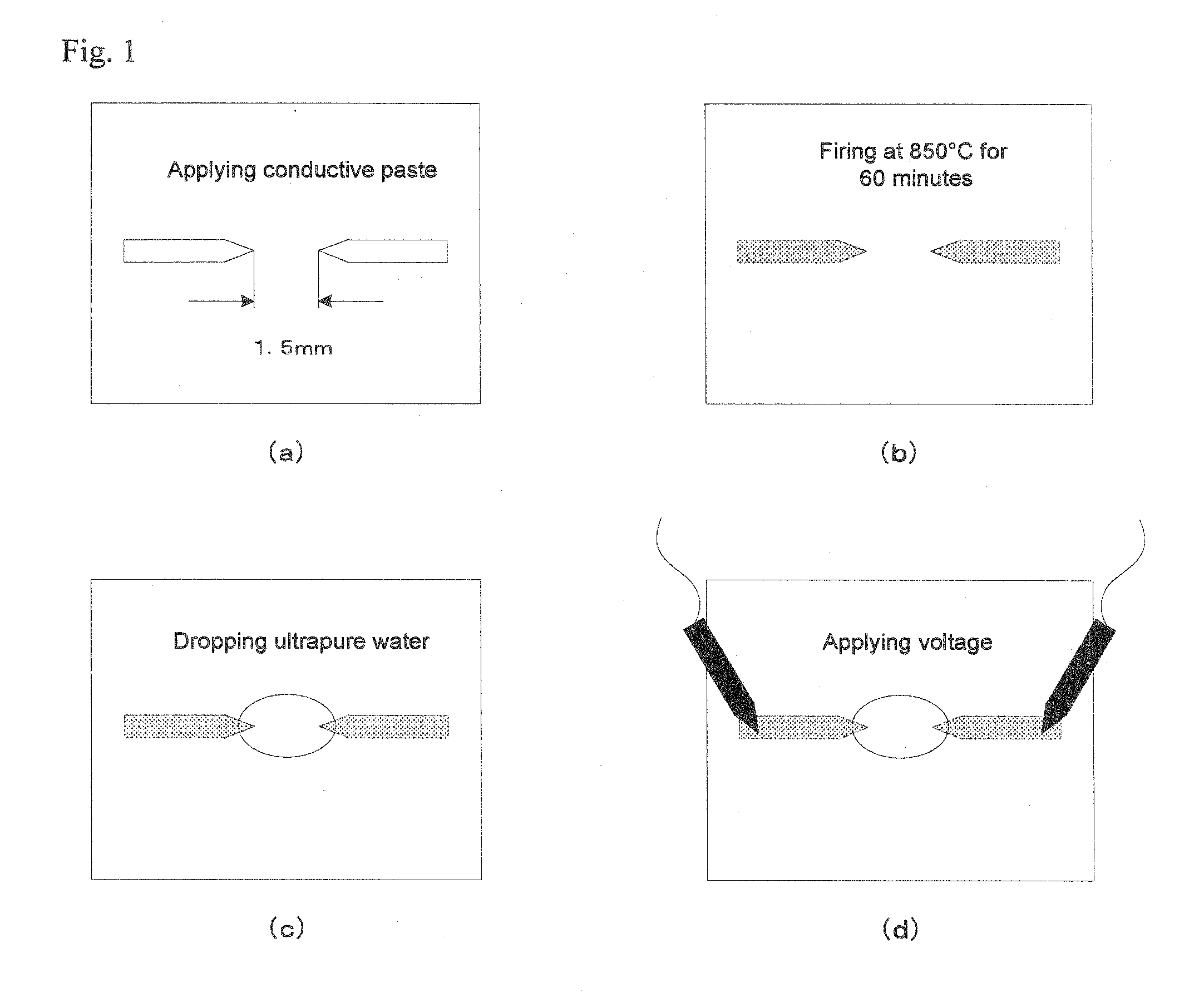

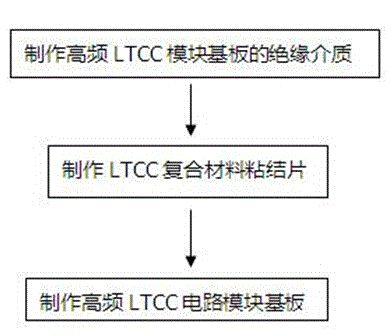

Manufacturing method of high-frequency LTCC circuit module substrate

InactiveCN104582291AHigh peel strengthIncrease flexibilityInsulating substrate metal adhesion improvementSpecific circuit substancesElectrical conductorMetallic materials

A manufacturing method of a high-frequency LTCC circuit module substrate comprises the following steps: (1) manufacturing an insulating medium layer of the high-frequency LTCC module substrate; (2) manufacturing LTCC composite adhesive sheets; (3) manufacturing the high-frequency LTCC circuit module substrate. The manufacturing method has the advantages as follows: the manufacturing method is suitable for circuit design with different signal frequencies; a metal material with high electrical conductivity is used as a conductor material, so that the quality factor of a circuit system can be favorably improved and the flexibility of the circuit design is improved; requirements on large current, high temperature resistance can be met, and thermal design of electronic equipment is optimized; the high-frequency LTCC circuit module substrate is high in reliability and is applicable to a severe environment, and the service life of the substrate is prolonged; adhesion between the copper foil layers and the insulating medium layer is facilitated, and the adhesive property is good; the peeling strength of the high-frequency LTCC circuit module substrate is improved, and the high-frequency LTCC circuit module substrate is especially applicable to a high heat-resistant environment; the ranges of the thicknesses of the copper foils can be widened; the copper foils with different thicknesses are selected according to different load current, load power as well as intercepting capabilities of the copper layers, so that the thicknesses of the copper layers are utilized to the maximum extent as much as possible.

Owner:TAIZHOU BOTAI ELECTRONICS

Layered solder material for bonding dissimilar electrodes, and method for bonding dissimilar electrodes to electronic components

ActiveUS20150314396A1Improve joint reliabilityAvoid formingPrinted circuit assemblingPrinted circuit aspectsAlloyElectronic component

When soldering a package having an electrode on which Ni / Au or Ag—Pd alloy is plated, to a printed circuit board having a Cu electrode or an electrode on which Cu is plated, a solid-phase diffusion layer is formed within a layered solder material for bonding different species of electrodes. The layered solder material is composed of a solder material of Sn—Ag—Cu series or Sn—Sb series and a solder material of Sn—Ag—Cu—Ni series or Sn—Pb series. The electrode on which Ni / Au or Ag—Pd alloy is plated and the Cu electrode or the electrode on which Cu is plated are soldered with the solder material of Sn—Ag—Cu series or Sn—Sb series being attached to the Cu electrode and the solder material of Sn—Ag—Cu—Ni series or Sn—Cu series being attached to the electrode on which Ni / Au or Ag—Pd alloy is plated. This restrains formation of intermetallic compounds and provides high bonding reliability.

Owner:SENJU METAL IND CO LTD

Cream solder and method of soldering electronic part

ActiveUS8968488B2Improve adhesionImprove stabilityPrinted circuit assemblingPrinted circuit aspectsThermal stabilitySolder material

A cream solder obtained by kneading an Sn—Ag—Cu alloy together with a flux, wherein the Sn—Ag—Cu alloy includes a mixture of a first powdery alloy and a second powdery alloy, the first powdery alloy is represented by an Sn—Ag phase diagram having a solid-liquid coexistence region and has a given silver amount which is larger than that in the eutectic composition (3.5 wt. % silver), and the second powdery alloy has a silver amount which is that in the eutectic composition (3.5 wt. % silver) or which is close to that in the eutectic composition and is smaller than that in the first powdery alloy. This cream solder has excellent strength and thermal stability, and satisfactory bonding properties. It is based on an inexpensive Sn—Ag—Cu solder alloy. It is suitable for use as a high-temperature-side lead-free solder material conformable to temperature gradation bonding. Also provided is a method of soldering.

Owner:NIHON HANDA +1

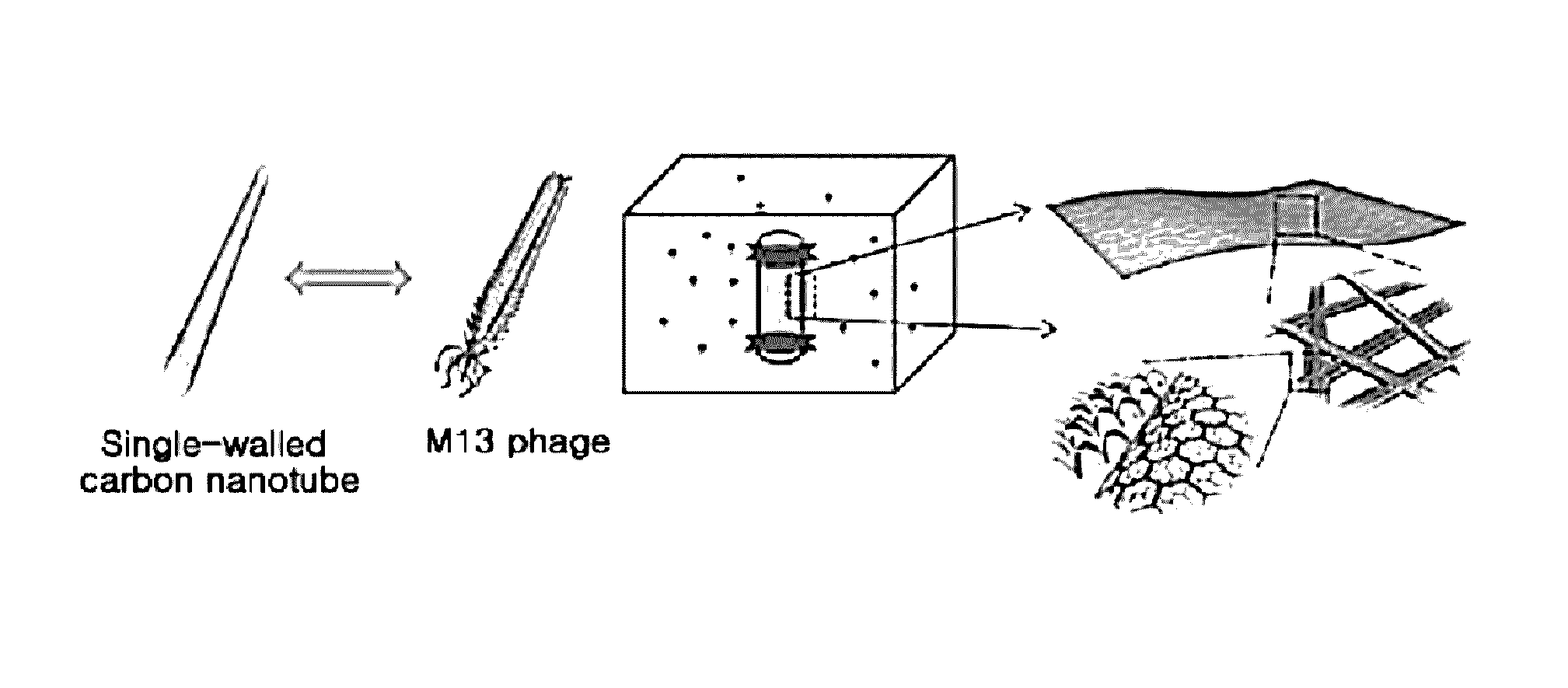

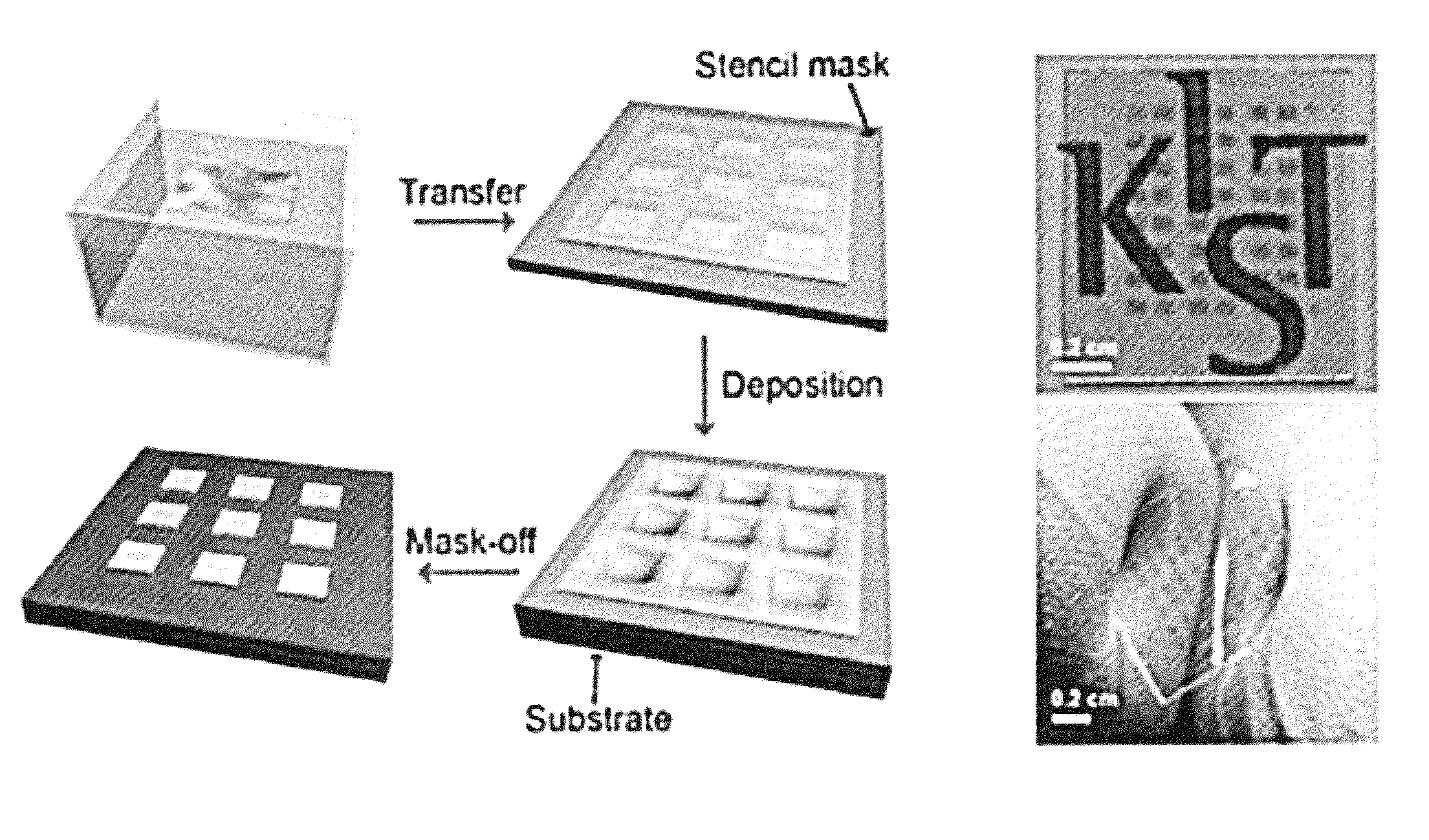

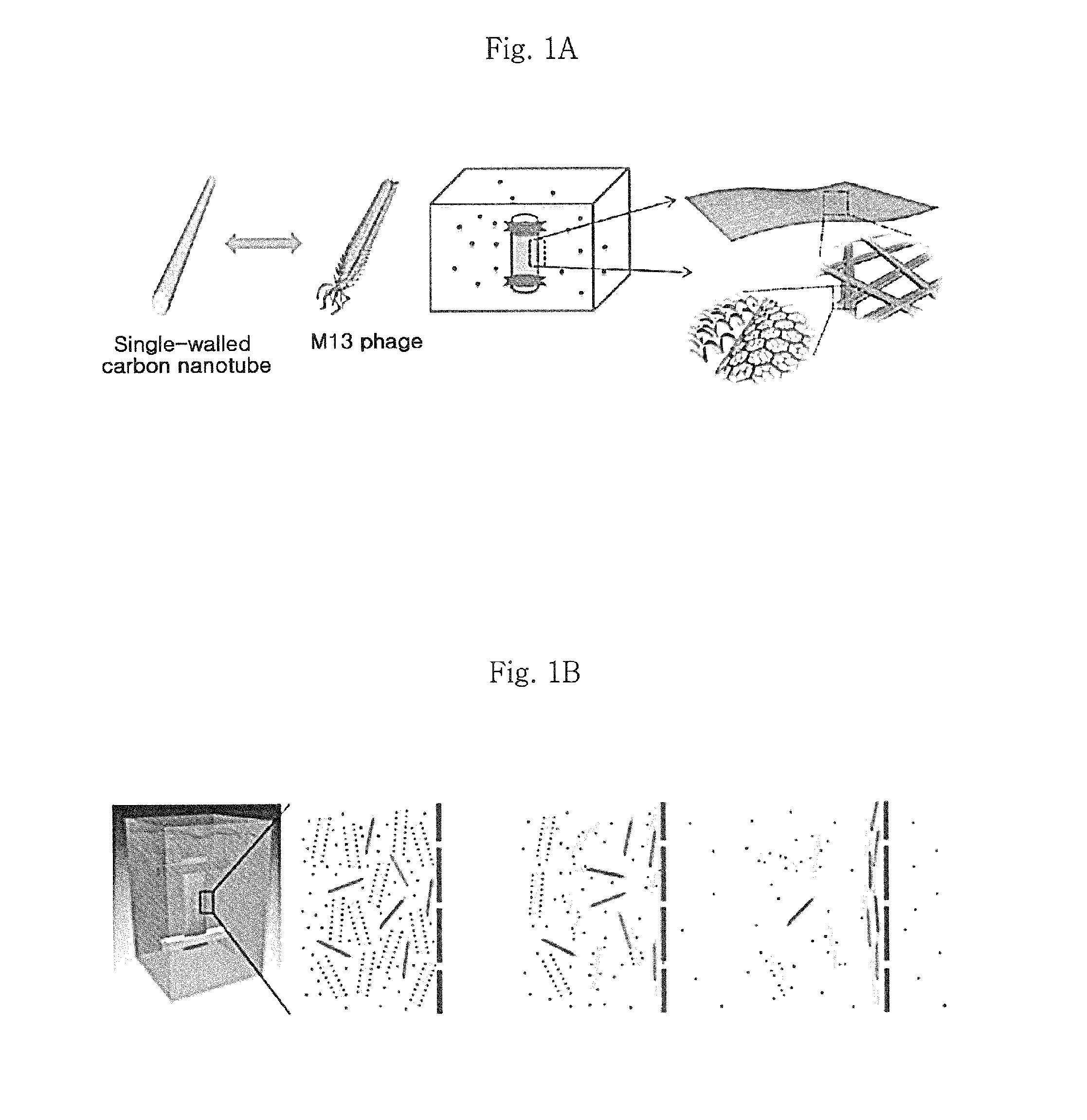

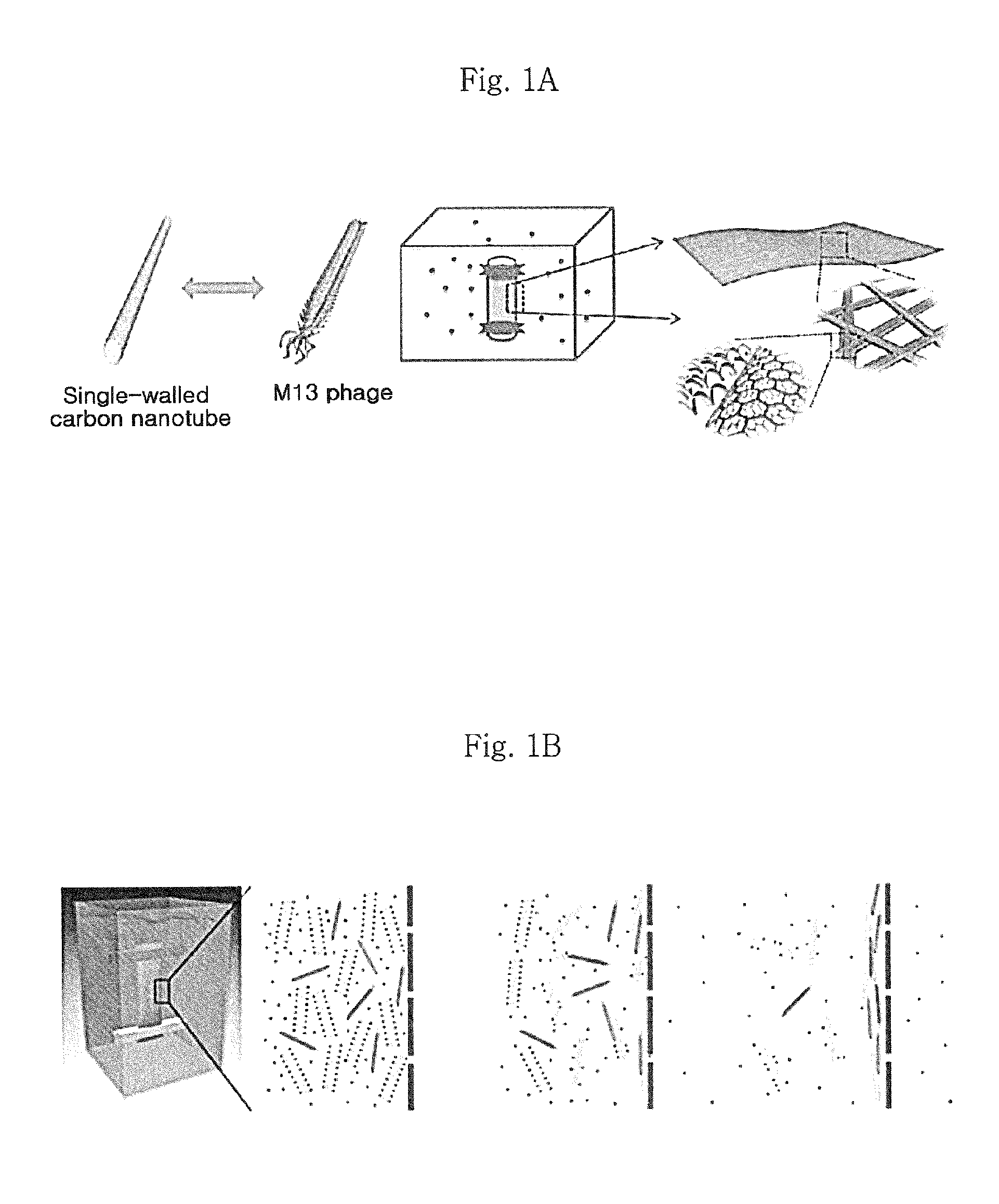

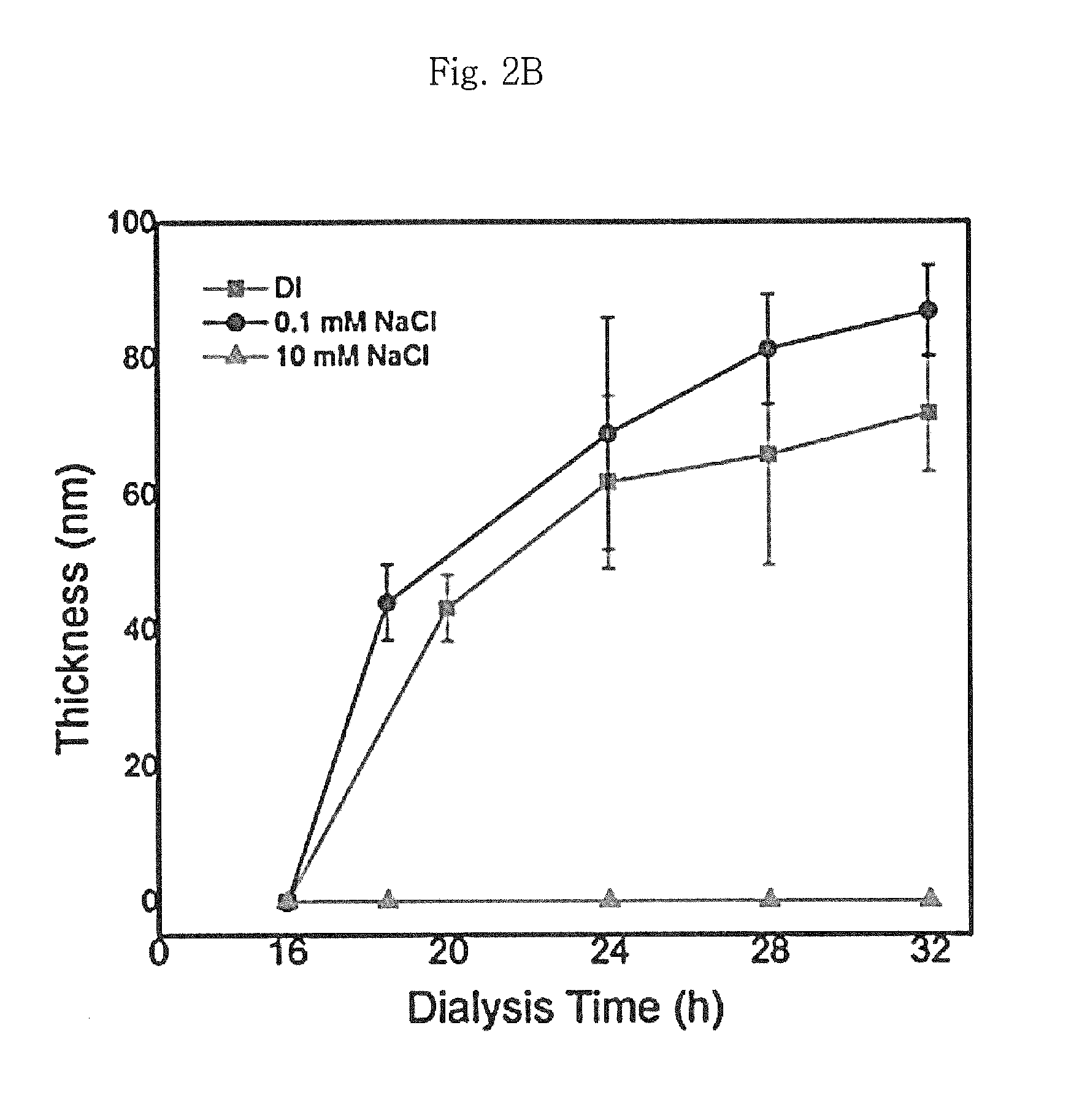

Hybrid electronic sheets

Provided is an electronic sheet including a graphitic material and a phage which displays a peptide having a binding ability to the graphitic material on its coat protein or a fragment thereof.

Owner:KOREA INST OF SCI & TECH

Flux Composition and Techniques for Use Thereof

The present invention is directed to flux compositions and uses thereof. One composition comprises an activator and a solvent being a glycerol ethoxylate with a molecular weight of 200-500. Another composition comprises an activator, a solvent being a glycerol ethoxylate with a molecular weight of 200-500 and an amine. A soldering method for joining objects is also provided, comprising the steps of applying a flux composition to at least a portion of one or more of the objects, and joining the objects.

Owner:IBM CORP

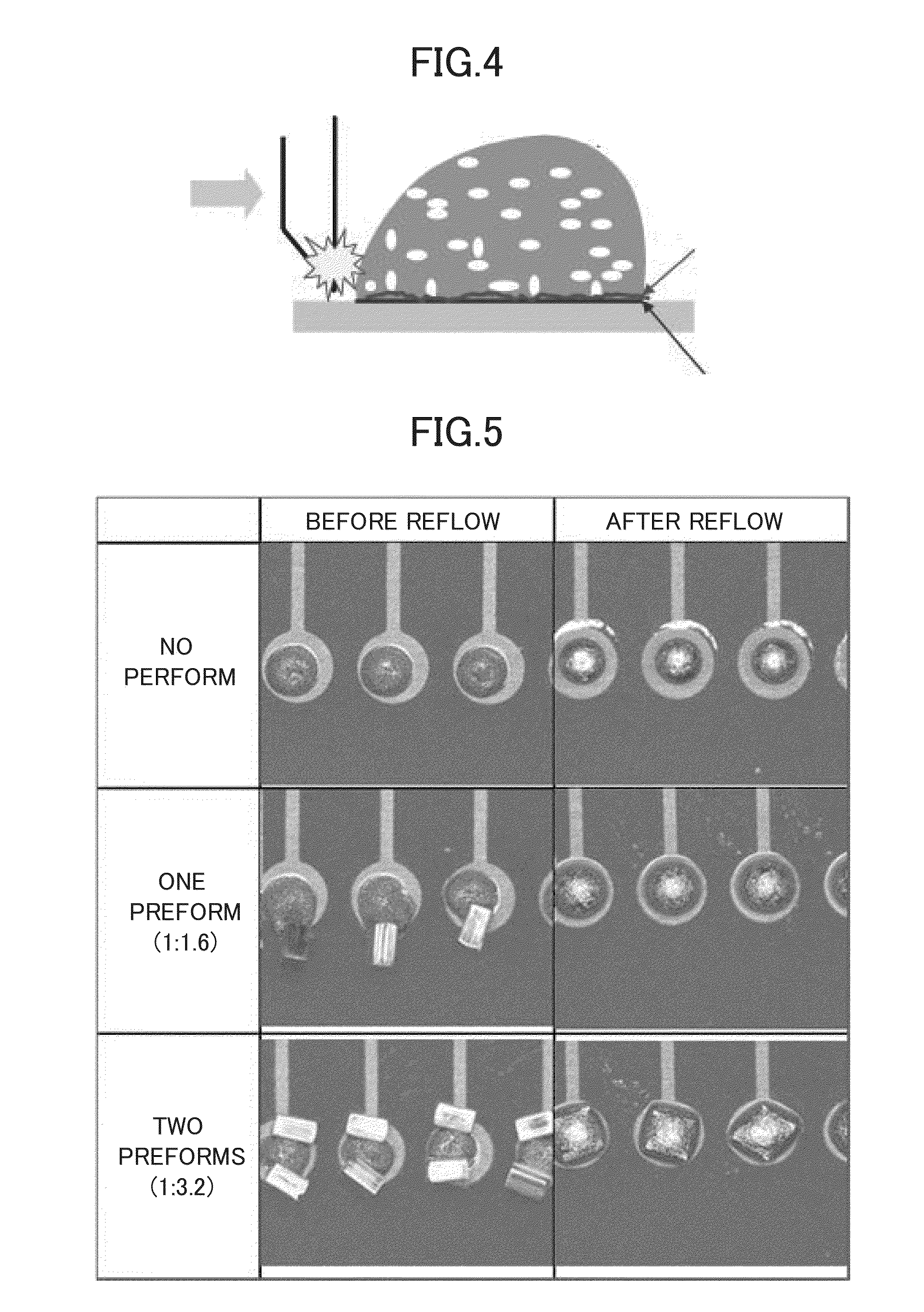

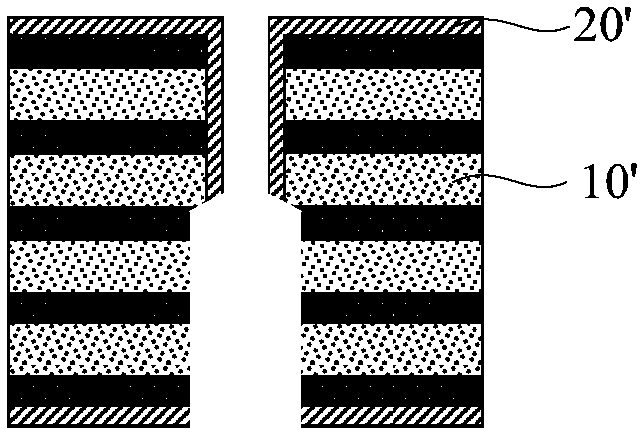

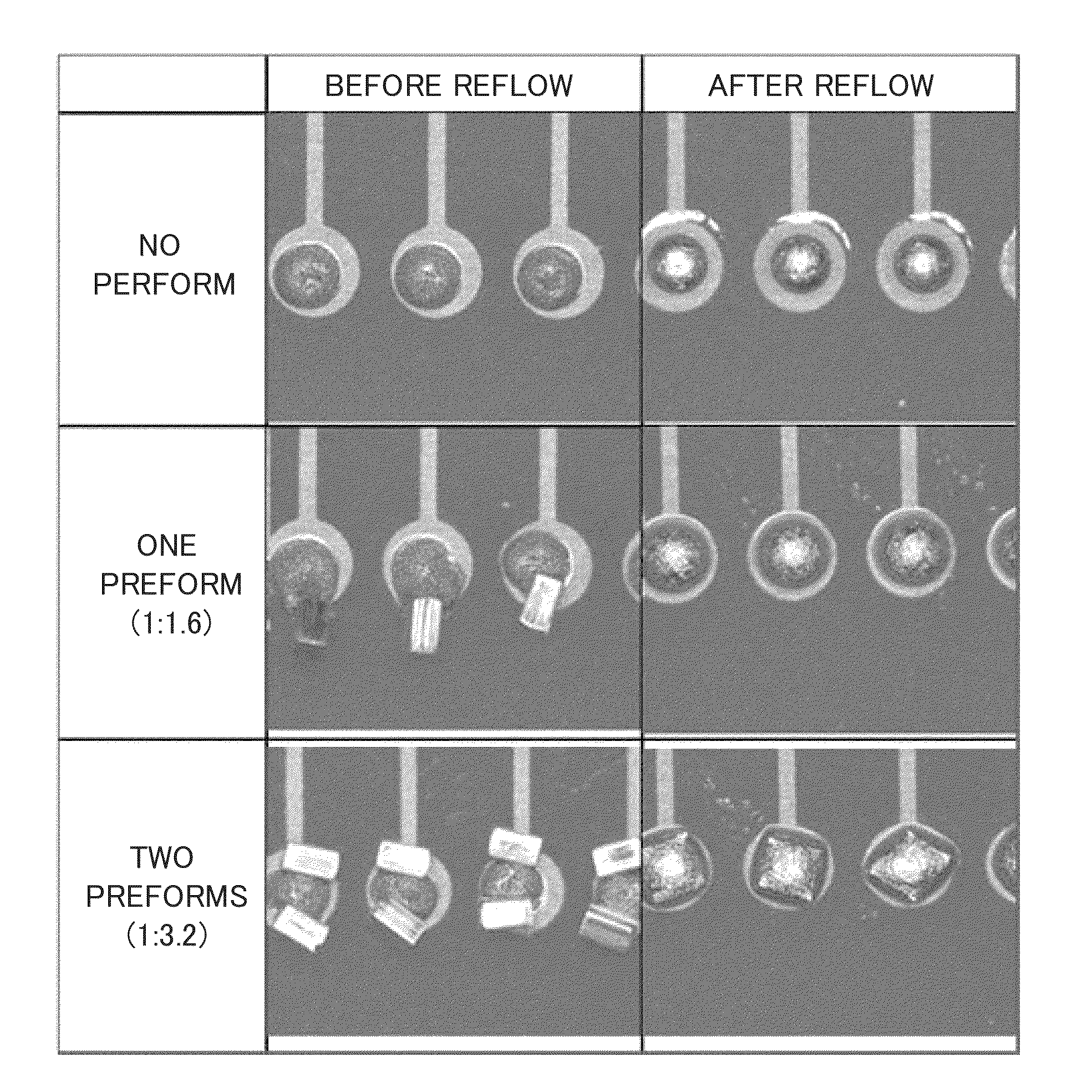

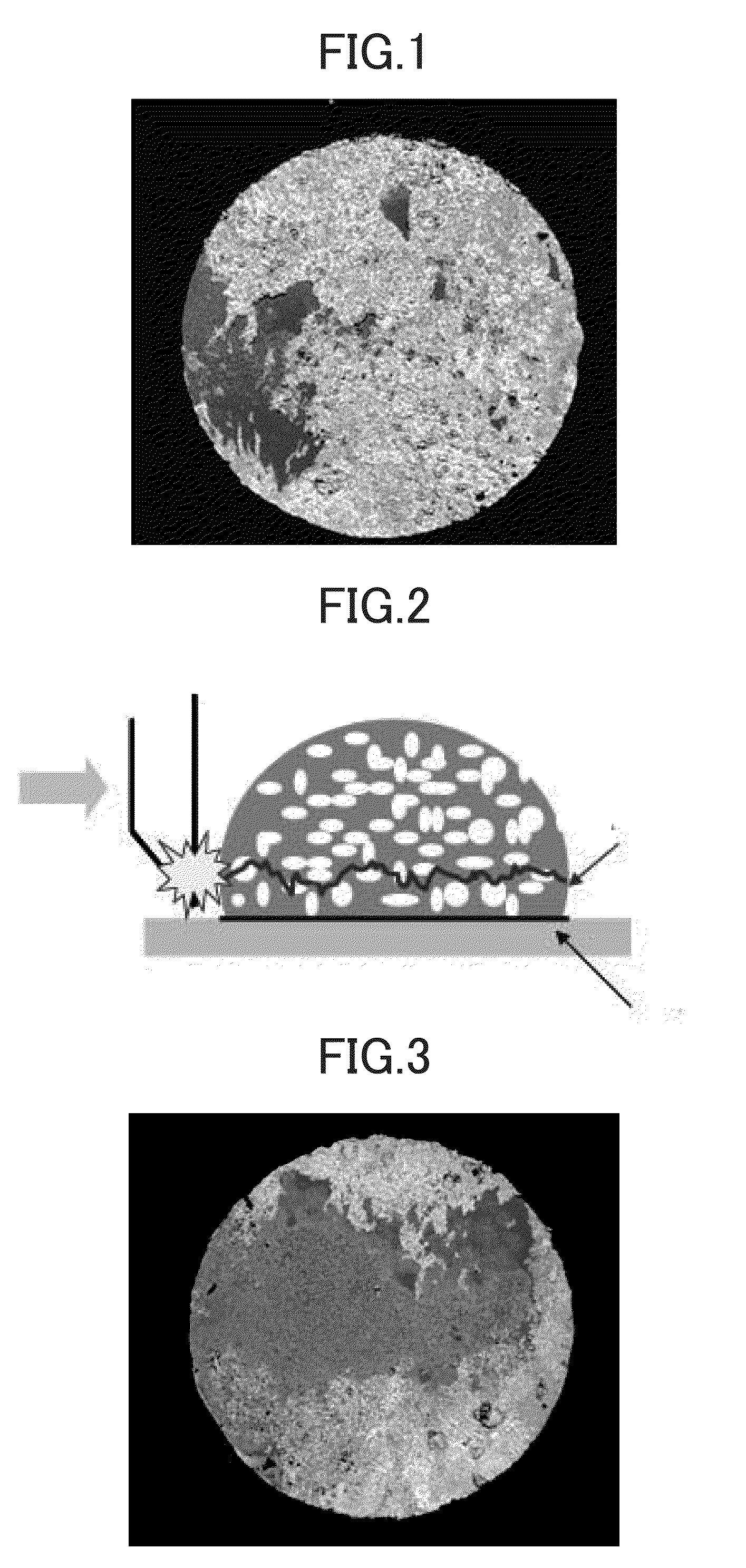

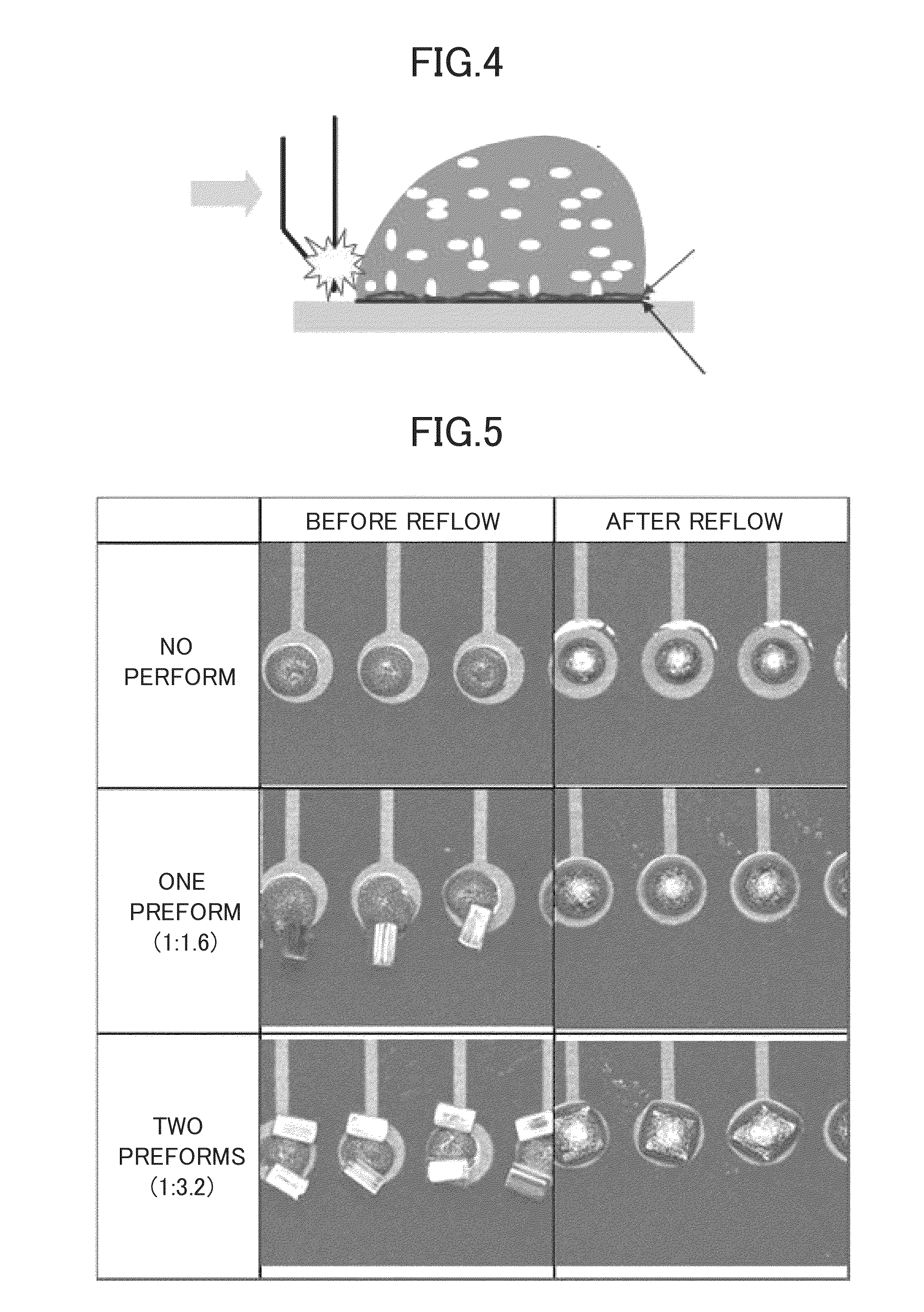

Soldering method using a low-temperature solder paste

ActiveUS20150282332A1Reduce power consumptionLow heat resistancePrinted circuit assemblingSpecific circuit substancesDrop impactSolder paste

Even if the strength of a solder composition close to a SnBi eutectic composition was improved, it was brittle, so when it was used for small electronic devices such as mobile phones or notebook computers, the resistance to drop impacts when the small electronic equipment was dropped was low. Therefore, interface peeling often took place between the soldered surface and a printed circuit board, resulting in the devices being destroyed. As disclosed, when soldering using a solder paste containing a SnBi-based low-temperature solder, at least one type of solder composition selected from a Sn—Ag, a Sn—Cu, and a Sn—Ag—Cu solder composition is diffused into the solder paste by simultaneously supplying at least one type of preform selected from a Sn—Ag, a Sn—Cu, and a Sn—Ag—Cu solder composition, whereby resistance to drop impacts is improved.

Owner:SENJU METAL IND CO LTD

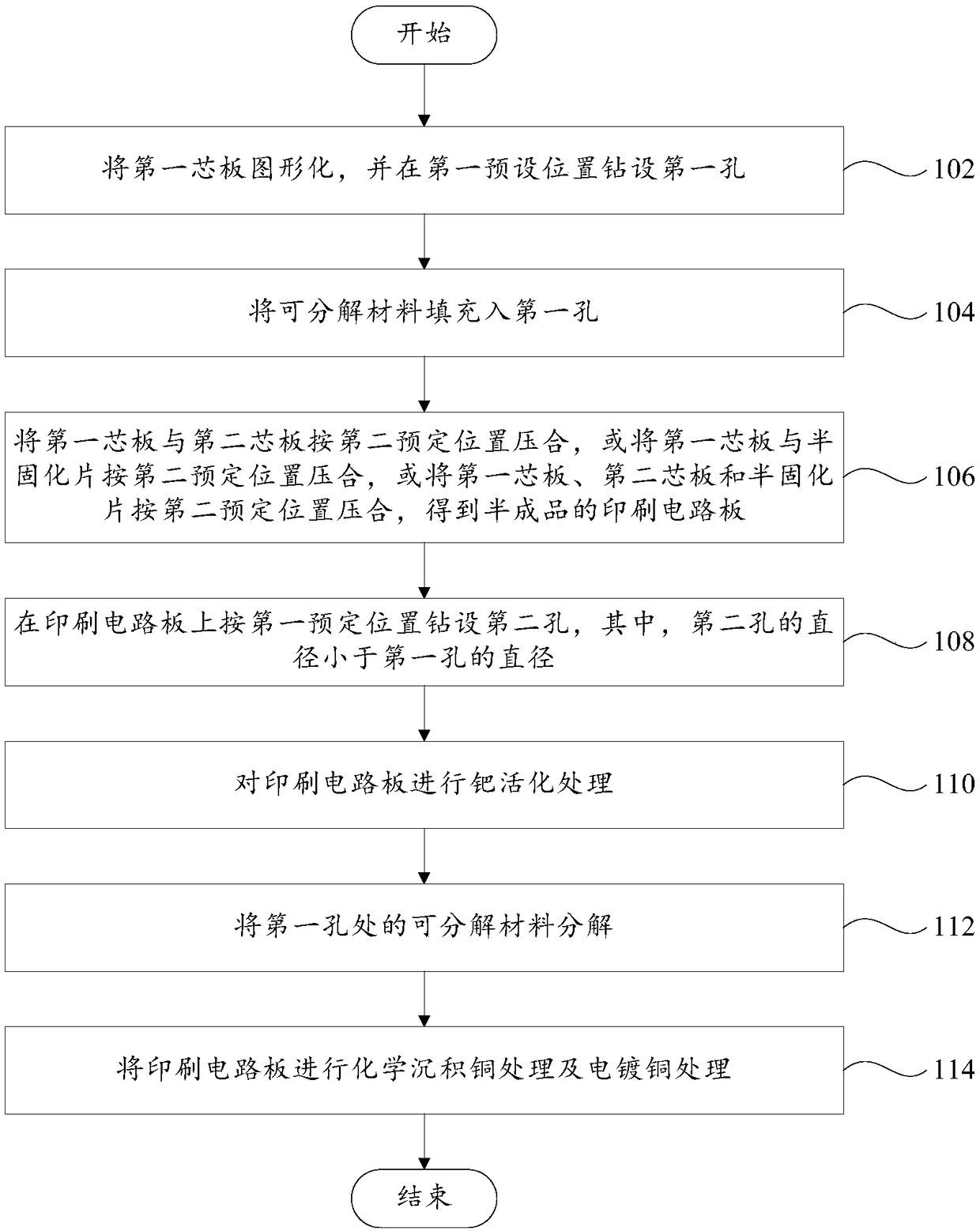

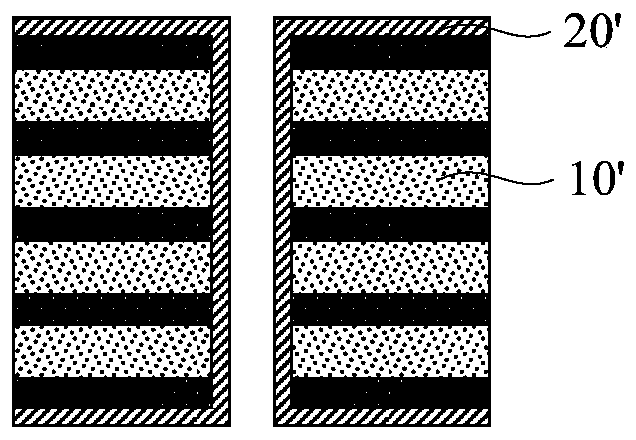

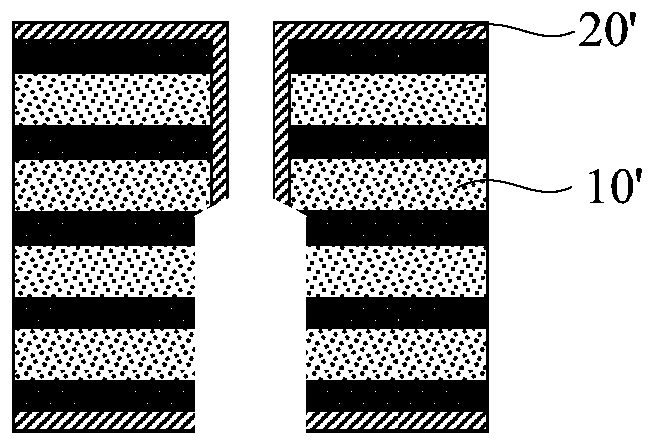

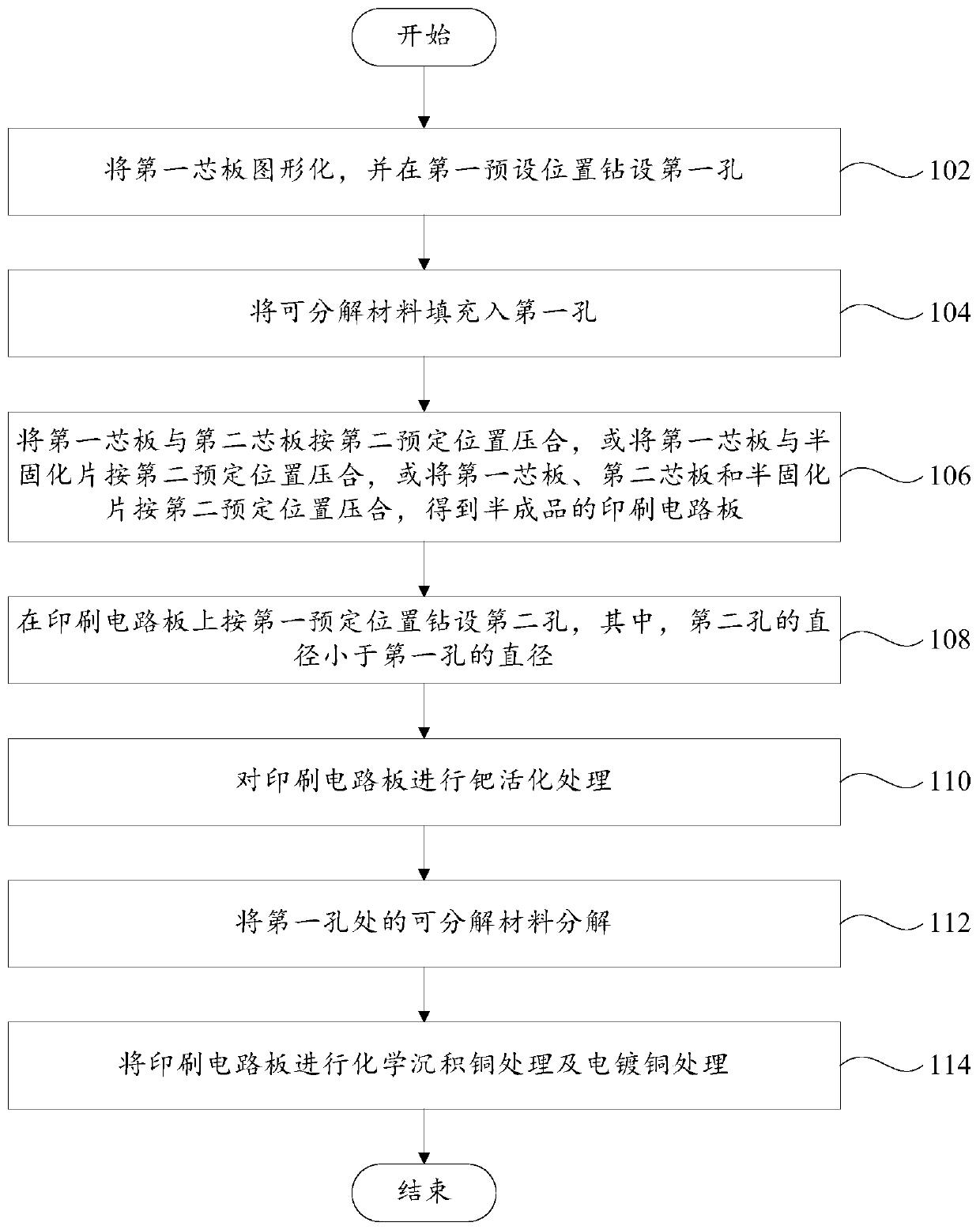

Manufacturing method of printed circuit board and printed circuit board

ActiveCN108697009AAvoid damageImprove reliabilitySpecific circuit substancesMultilayer circuit manufactureEngineeringBiological activation

The present invention provides a manufacturing method of a printed circuit board and a printed circuit board. According to the manufacturing method of the printed circuit board, after a first core board is patternized, a first hole is formed at the predetermined position of the first core board by means of drilling; the first hole is filled with a decomposable material; the first core board and the other core board are laminated, and a second hole is formed at the same position with the first hole; the diameter of the first hole is larger than the diameter of the second hole, so that after thedrilling of the second hole is completed, the decomposable material is still left on the hole wall of the first core boar, and therefore, palladium can be deposited on the decomposable material afterpalladium activation treatment is carried out in a PTH process; and after the decomposable material is decomposed, the palladium is removed, so that a copper layer cannot be formed on the surface ofthe hole wall of the first core board during copper deposition and copper electroplating.

Owner:NEW FOUNDER HLDG DEV LLC +1

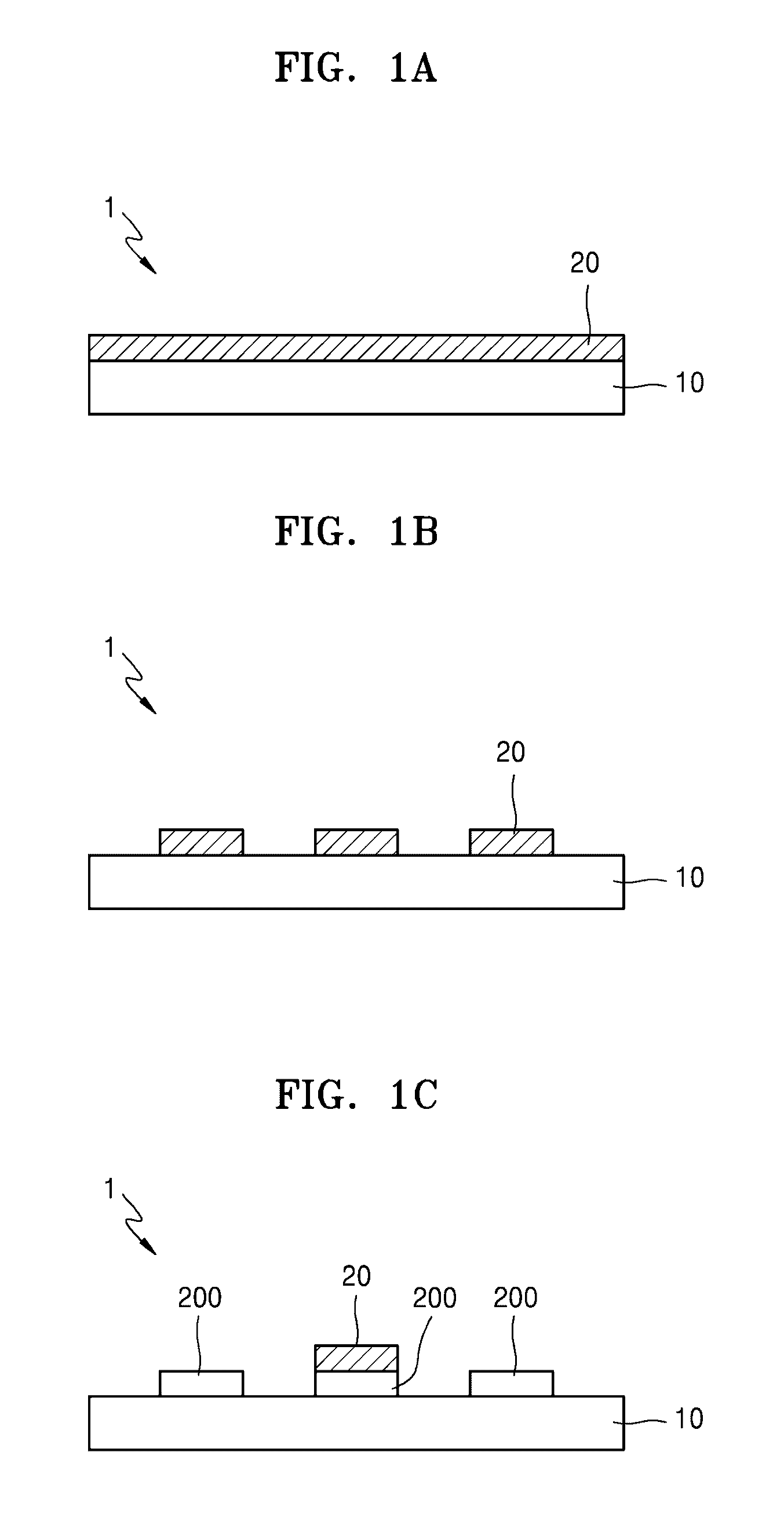

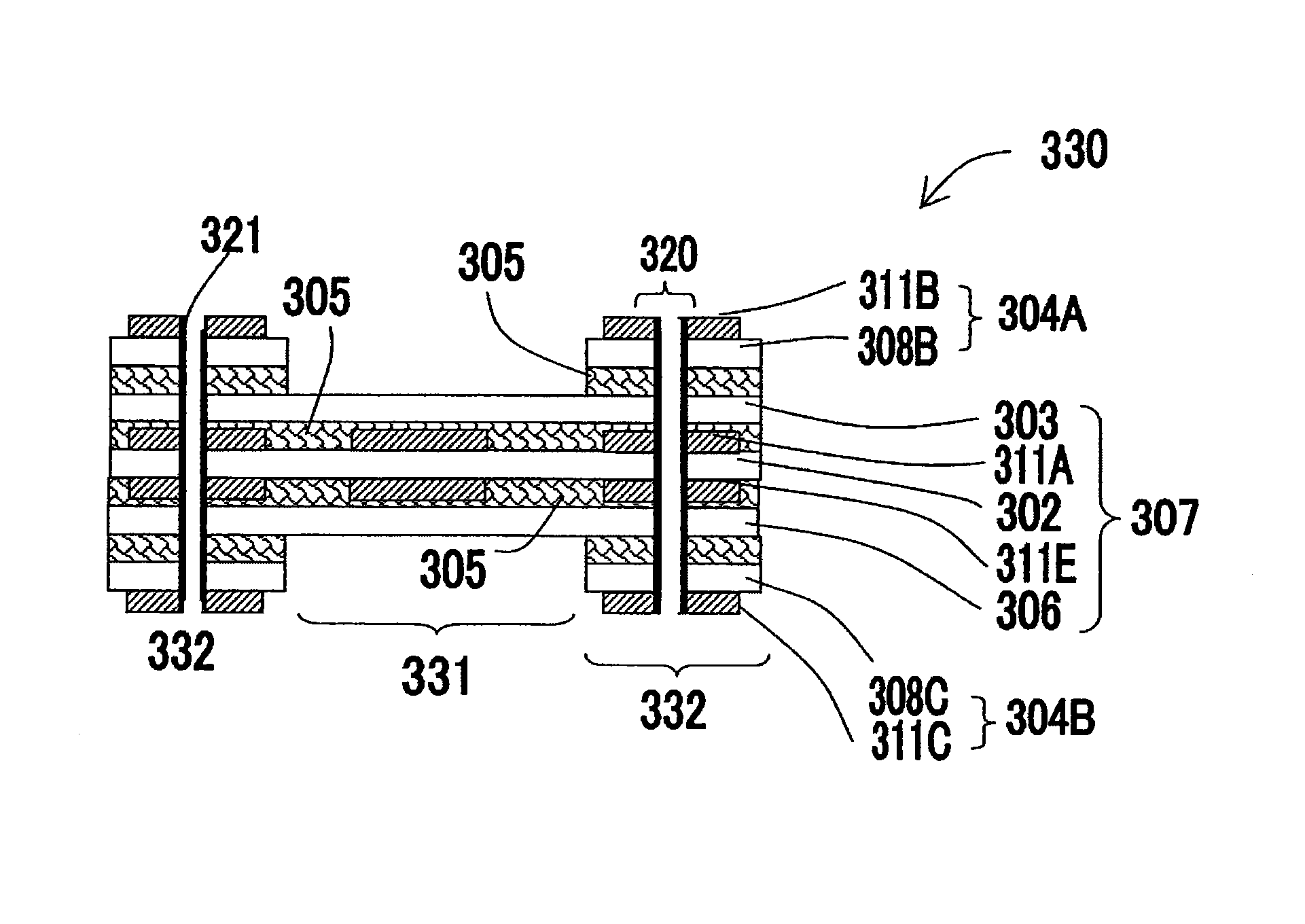

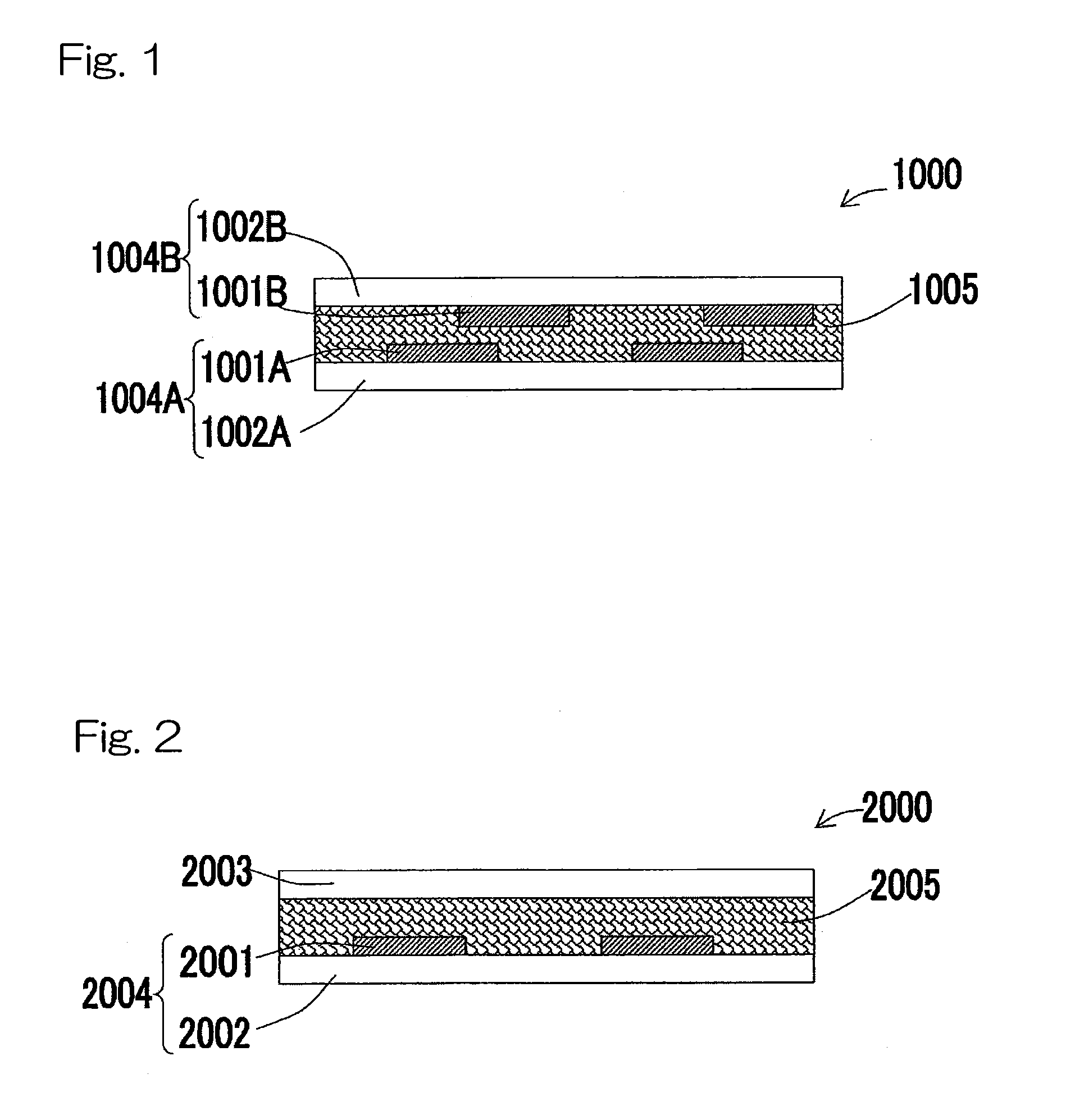

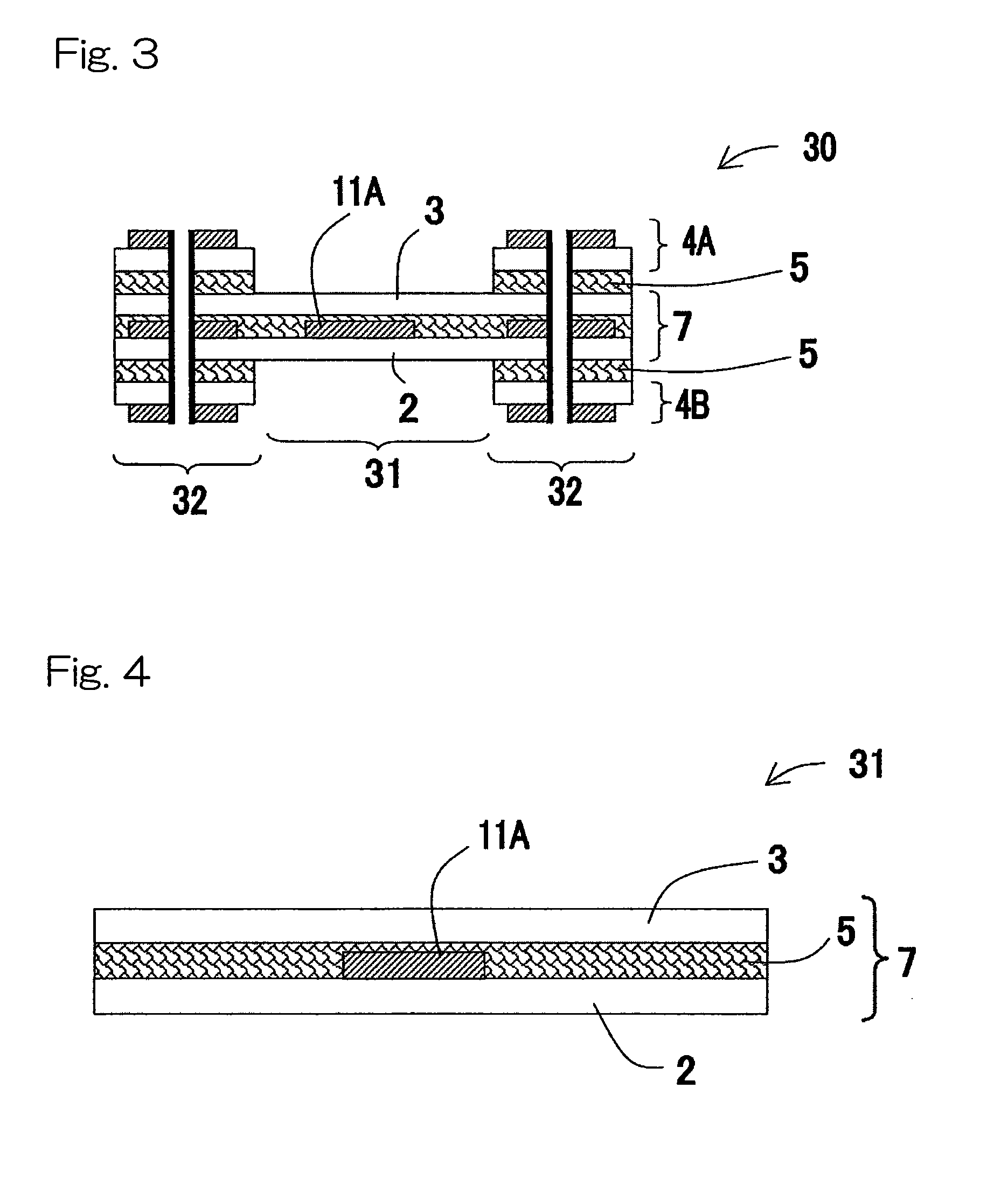

Circuit board and method for manufacturing same

ActiveUS9439303B2Improve adhesionReduce roughnessLiquid crystal compositionsHigh frequency circuit adaptationsFlexible circuitsEngineering

Owner:KURARAY CO LTD

Soldering method using a low-temperature solder paste

ActiveUS9402321B2Low heat resistanceReduce power consumptionPrinted circuit assemblingSpecific circuit substancesDrop impactSolder paste

Even if the strength of a solder composition close to a SnBi eutectic composition was improved, it was brittle, so when it was used for small electronic devices such as mobile phones or notebook computers, the resistance to drop impacts when the small electronic equipment was dropped was low. Therefore, interface peeling often took place between the soldered surface and a printed circuit board, resulting in the devices being destroyed. As disclosed, when soldering using a solder paste containing a SnBi-based low-temperature solder, at least one type of solder composition selected from a Sn—Ag, a Sn—Cu, and a Sn—Ag—Cu solder composition is diffused into the solder paste by simultaneously supplying at least one type of preform selected from a Sn—Ag, a Sn—Cu, and a Sn—Ag—Cu solder composition, whereby resistance to drop impacts is improved.

Owner:SENJU METAL IND CO LTD

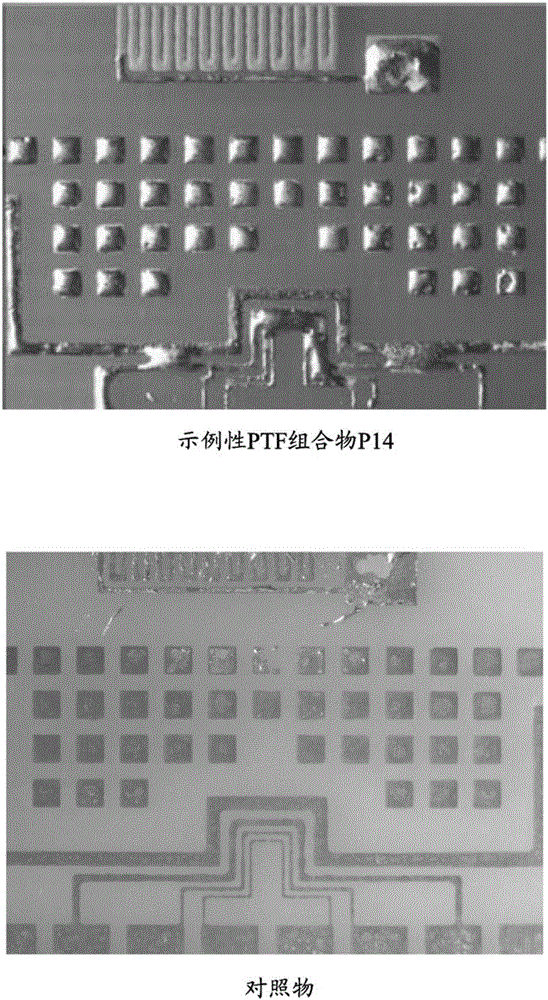

Solderable conductive polymer thick film composition

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Manufacturing method of printed circuit board and printed circuit board

ActiveCN108697009BAvoid damageImprove reliabilitySpecific circuit substancesMultilayer circuit manufactureMechanical engineeringPrinted circuit board

The present invention provides a manufacturing method of a printed circuit board and a printed circuit board. According to the manufacturing method of the printed circuit board, after a first core board is patternized, a first hole is formed at the predetermined position of the first core board by means of drilling; the first hole is filled with a decomposable material; the first core board and the other core board are laminated, and a second hole is formed at the same position with the first hole; the diameter of the first hole is larger than the diameter of the second hole, so that after thedrilling of the second hole is completed, the decomposable material is still left on the hole wall of the first core boar, and therefore, palladium can be deposited on the decomposable material afterpalladium activation treatment is carried out in a PTH process; and after the decomposable material is decomposed, the palladium is removed, so that a copper layer cannot be formed on the surface ofthe hole wall of the first core board during copper deposition and copper electroplating.

Owner:NEW FOUNDER HLDG DEV LLC +1

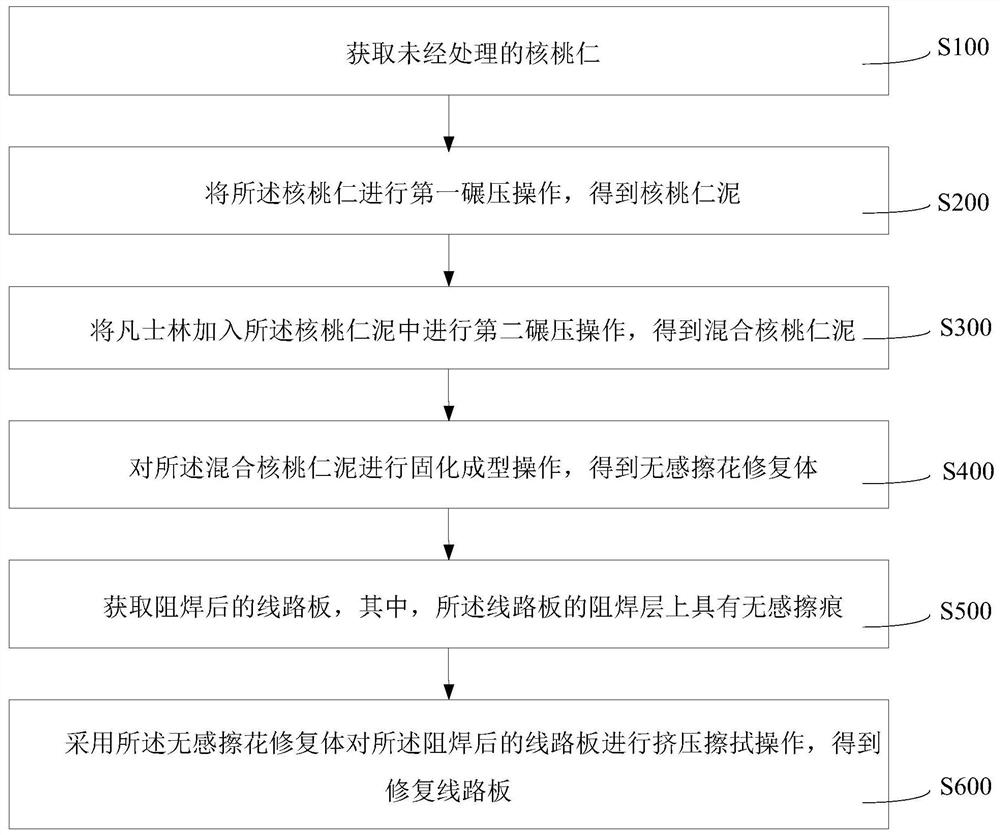

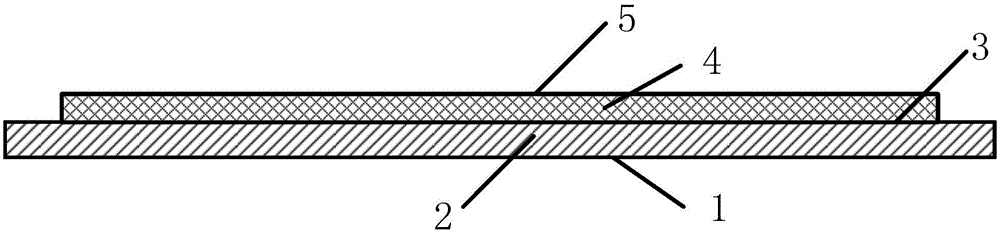

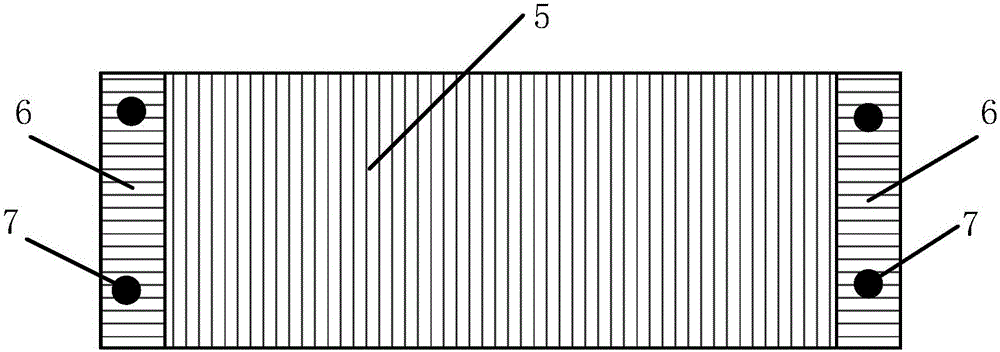

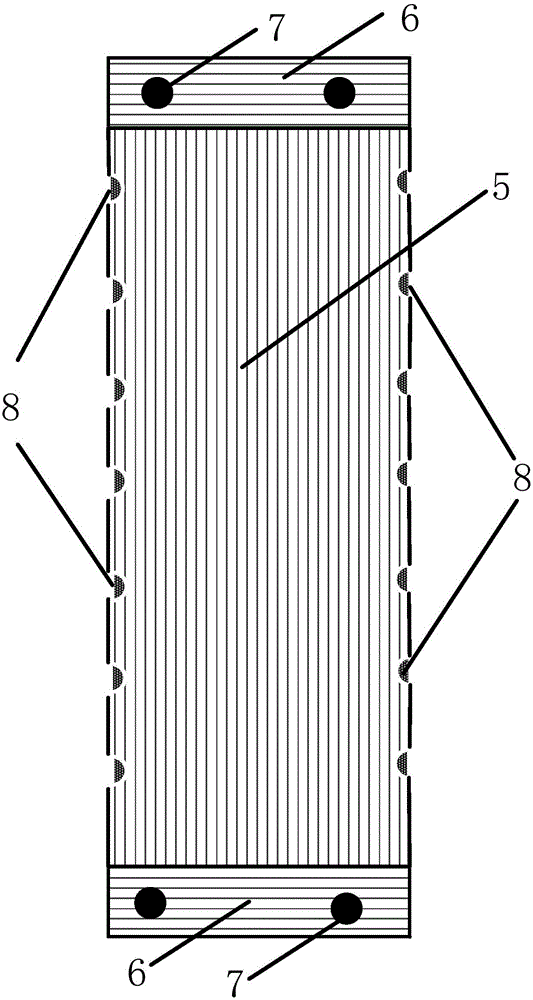

Circuit board and its non-inductive scratch repair process

ActiveCN112739023BGood lookingImprove repair effectPost-manufacturing circuit processesSpecific circuit substancesSolder maskProcess engineering

The present application provides a non-inductive scratch repair process for circuit boards. The above-mentioned non-inductive rubbing repair process for circuit boards includes the following steps: obtaining untreated walnut kernels; performing a first rolling operation on the walnut kernels to obtain walnut kernel mud; adding Vaseline to the walnut kernel mud for a second rolling operation , to obtain mixed walnut kernel paste; solidify and form the mixed walnut kernel paste to obtain a non-inductive scratch restoration; obtain a circuit board after solder masking, wherein there are non-inductive scratches on the solder mask layer of the circuit board; Squeeze and wipe the circuit board after the solder resistance with the scratch-scratch restoration body to obtain the repaired circuit board. The above-mentioned non-inductive scratch repair process for circuit boards can better repair the non-inductive scratches and improve the appearance of the circuit board.

Owner:CAMELOT QINGYUAN HYTEC TECH INVESTMENT

Circuit board with shielding structure and preparation method thereof

ActiveCN105101622AImprove anti-interference functionImprove shielding effectCross-talk/noise/interference reductionPrinted circuit aspectsParasitic capacitanceEngineering

The present invention provides a circuit board with a shielding structure and a preparation method thereof. The circuit board includes: a first shielding layer, a second shielding layer, a circuit layer arranged between the first shielding layer and the second shielding layer, a first insulating layer arranged between the circuit layer and the first shielding layer, and a second insulating layer arranged between the circuit layer and the second shielding layer. The second shielding layer and the second insulating layer are arranged on the circuit layer and are smaller than the circuit layer in size. When the second shielding layer and the second insulating layer cover the circuit layer, at least one edge part of the circuit layer is exposed outside the second shielding layer, and the exposed edge part is provided with a plurality of metal electrodes connected to an external circuit board. According to the technical scheme of the present invention, shielding layers are arranged on two sides of the circuit layer so that a shielding processing to a circuit does not require a shielding cover; and the metal electrodes for connection on the circuit layer are exposed outside the insulating layer directly so as to avoid parasitic capacitances, and an anti-interference function of the circuit board is greatly enhanced.

Owner:ZHEJIANG ZAPON ELECTRONICS TECH

Hybrid electronic sheets

ActiveUS9226403B2Superior and tunable electrical propertyIncrease the areaSpecific circuit substancesConductive pattern formationNon destructiveElectricity

In accordance with the present disclosure, a hybrid electronic sheet which exhibits superior electrical property and allows biomaterial functionalization and flexible device patterning may be provided by binding a graphitic material in colloidal state to a biomaterial capable of binding thereto specifically and nondestructively. Since the electronic sheet is an electronic sheet wherein a biomaterial and an electrical material (graphitic material) are hybridized, it exhibits good compatibility with biomaterials and can be further functionalized with, for example, an enzyme that selectively reacts with a biochemical substance. Accordingly, an electrical material and a chemical or biological material may be effectively nanostructurized and it can be realized as a multi-functional, high-performance electronic sheet.

Owner:KOREA INST OF SCI & TECH

Non-etching non-resist adhesion composition and method of preparing a work piece

To achieve good adherence of a resist coating, more specifically a photo imageable resist coating, to a copper base while ensuring that the copper base being very thin is not compromised, a non-etching non-resist composition for the treatment of the copper base is provided, said composition comprising at least one adhesion agent selected from the group comprising (i) heterocyclic compounds comprising at least one thiol moiety and (ii) quaternary ammonium polymers having the following general chemical formula: {N+(R3)(R4)—(CH2)a—N(H)—C(Y)—N(H)—(CH2)b—N+(R3)(R4)—R5}n 2n X−, with R1, R2, R3, R4, R5, Y and X− being defined as claimed.

Owner:ATOTECH DEUT GMBH

Thermally Conductive Flexible Adhesives for Aerospace Applications

ActiveCN104861909BNon-macromolecular adhesive additivesFinal product manufactureEpoxyAdhesive cement

The present invention relates to thermally conductive flexible adhesives for aerospace applications. The present invention provides methods for forming thermally conductive flexible bonds for circuit boards of unmanned spacecraft and other types of aircraft. The present invention also provides methods of making adhesive materials for forming these bonds, including methods of making treated filler particles. In some aspects, the adhesive material includes filler particles having organic functional groups, such as boron nitride particles treated in silane. These particles can be combined with a urethane-modified epoxy resin to form an adhesive material. The weight ratio of particles in the adhesive material may be about 40% to 60%. The adhesive material may be thermally cured using temperatures below 110°C to prevent damage to the bonded electronic components. The cured adhesive may have a thermal conductivity measured in vacuum of at least about 2 W / m K, and may have a glass transition temperature of less than -40°C.

Owner:THE BOEING CO

Hybrid electronic sheets

ActiveUS20150305163A1Superior and tunable electrical propertyIncrease the areaDecorative surface effectsSpecific circuit substancesNano structuringEngineering

In accordance with the present disclosure, a hybrid electronic sheet which exhibits superior electrical property and allows biomaterial functionalization and flexible device patterning may be provided by binding a graphitic material in colloidal state to a biomaterial capable of binding thereto specifically and nondestructively. Since the electronic sheet is an electronic sheet wherein a biomaterial and an electrical material (graphitic material) are hybridized, it exhibits good compatibility with biomaterials and can be further functionalized with, for example, an enzyme that selectively reacts with a biochemical substance. Accordingly, an electrical material and a chemical or biological material may be effectively nanostructurized and it can be realized as a multi-functional, high-performance electronic sheet.

Owner:KOREA INST OF SCI & TECH

Conductive paste

ActiveUS9574091B2Improve adhesionIncrease resistancePrinted circuit aspectsNon-conductive material with dispersed conductive materialConductive pasteFrit

Owner:NAMICS CORPORATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com