Solderable conductive polymer thick film composition

A technology of conductive polymer, thick film composition, applied in welding equipment, conductive paint, welding medium, etc., can solve problems such as difficult welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

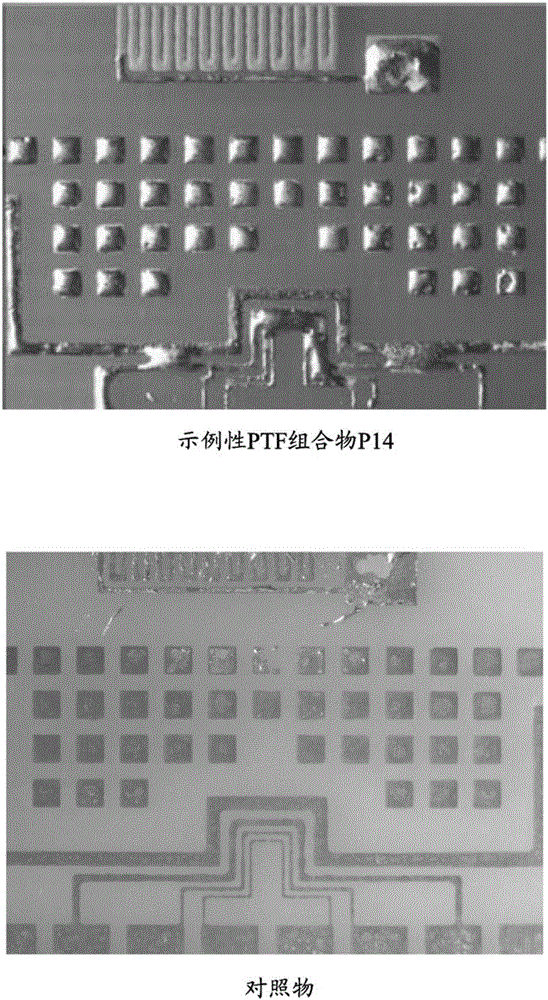

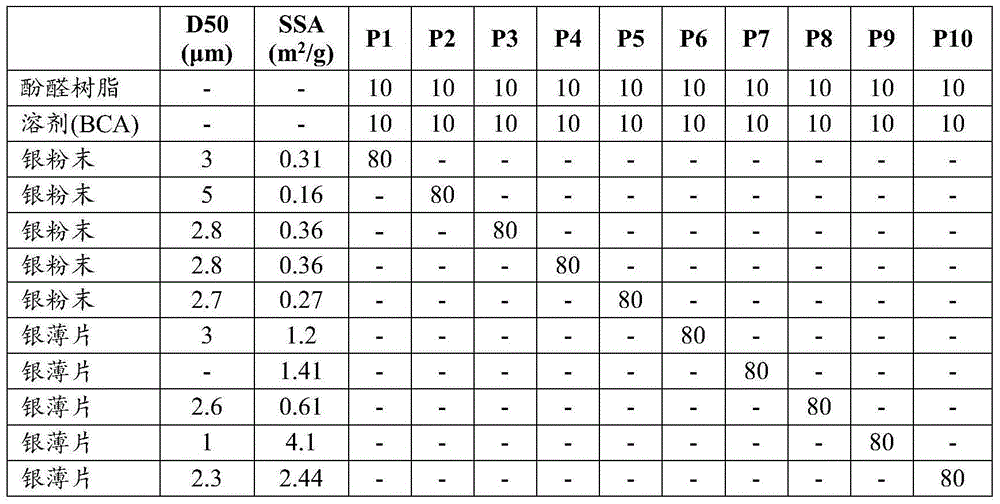

[0056] Ten solderable PTF compositions were prepared using the materials listed in Table 1 below. The phenolic resin in each of the compositions was Varcum 29112, commercially available from Durez Corporation of Addison, Texas, and the solvent was butyl carbitol acetate, commercially available. All amounts are provided in weight percent of the total PTF composition. Each PTF composition contains 50 and specific surface area (SSA) of silver powder or silver flake.

[0057] Table 1. Exemplary PTF Compositions P1-P10

[0058]

[0059] Each PTF composition was then coated onto an FR4 substrate (glass reinforced epoxy laminate) using the doctor blade method. Two mil tape was applied to both sides of the substrate, leaving about 0.75 inches of unobstructed surface area of the FR4 substrate. A small amount of the PTF composition was added between the tapes and a blade was used to smooth out the PTF composition between the tape pieces. The tape was then removed leaving a smo...

Embodiment 2

[0063] Conductive PTF compositions were prepared using the starting materials listed in Table 3 below. The components used were as follows: phenolic resin and solvent #1 were the same as used in Example 1; polyimide resin was 14% polyimide resin, 26% gamma butyrolactone commercially available from Alfa Aesar of Ward Hill, MA and 60% sulfolane; the epoxy resin is commercially available from EpoxyTechnology, Inc. of Billerica, Massachusetts. H61-110 unfilled epoxy; solvent #2 is gamma butyrolactone; hardener is boron fluoride monoethylamine; thinner is Erisys commercially available from Emerald Performance Materials of Moorestown, NJ TM GE-21; and thixotrope is commercially available from BYK Additives, Inc. of Austin, Texas. . Controls were formulated with silver flake and polyimide / epoxy resin, while all exemplary compositions were formulated with silver powder and a combination of silver flake and phenolic resin. All amounts are provided in weight percent of the total PT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com