Manufacturing method of high-frequency LTCC circuit module substrate

A circuit module and manufacturing method technology, which are applied in the manufacture of printed circuits, improvement of metal adhesion of insulating substrates, printed circuits, etc., to achieve the effects of optimizing heat dissipation design, improving peel strength, and improving quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

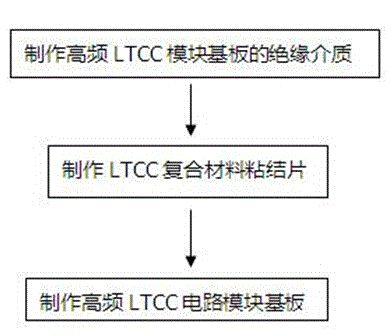

[0014] Such as figure 1 As shown, a method for manufacturing a high-frequency LTCC circuit module substrate, including step 1, making an insulating medium layer for a high-frequency LTCC module substrate, selecting a proportioning scheme according to the dielectric constant requirement, using PTFE powder and LTCC powder to mix, according to the medium The thickness of the layer is required to be controlled, and the dielectric material is formed by ball milling for 48 hours, and then the dielectric material is placed in a mold and pressed at a high temperature of 280-300°C to form an insulating dielectric layer; Step 2 is to make an LTCC composite bonding sheet, and the thickness is selected to be less than 0.025mm LTCC ceramic powder is put into PTFE resin and pre-impregnated by a dipping machine, and then sintered at a high temperature of 260-270°C to make an LTCC composite bonded sheet; Step 3, making a high-frequency LTCC circuit module substrate, select the thickness 35um-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com