Electronic device and assembling method thereof

The technology of an electronic device and assembly method, which is applied in the direction of output power conversion device, electrical equipment shell/cabinet/drawer, circuit, etc., can solve the problem that power conversion device consumes a large amount of power, cannot effectively transmit heat energy, and has limited heat dissipation efficiency and other issues, to reduce the risk of thermal failure, save assembly time, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

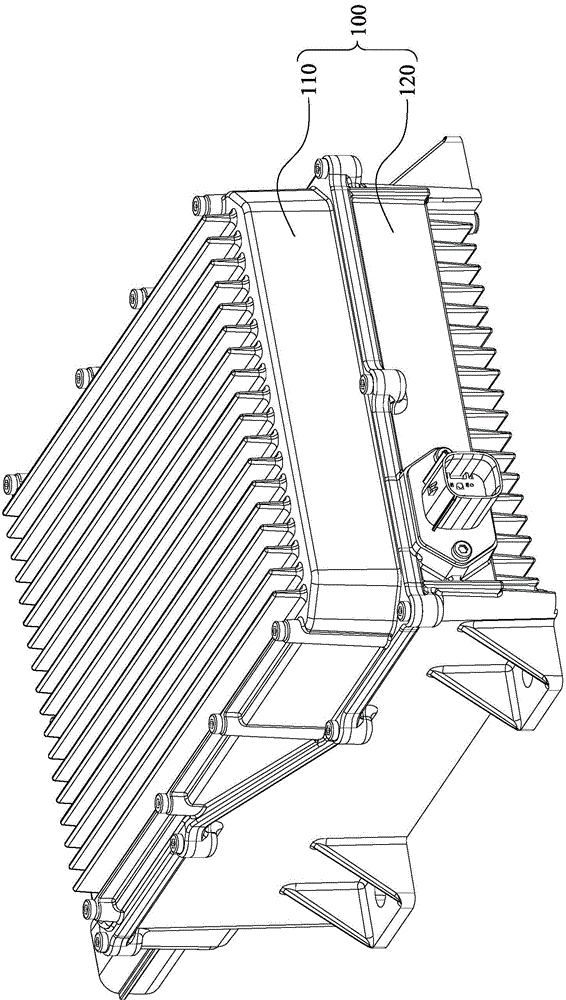

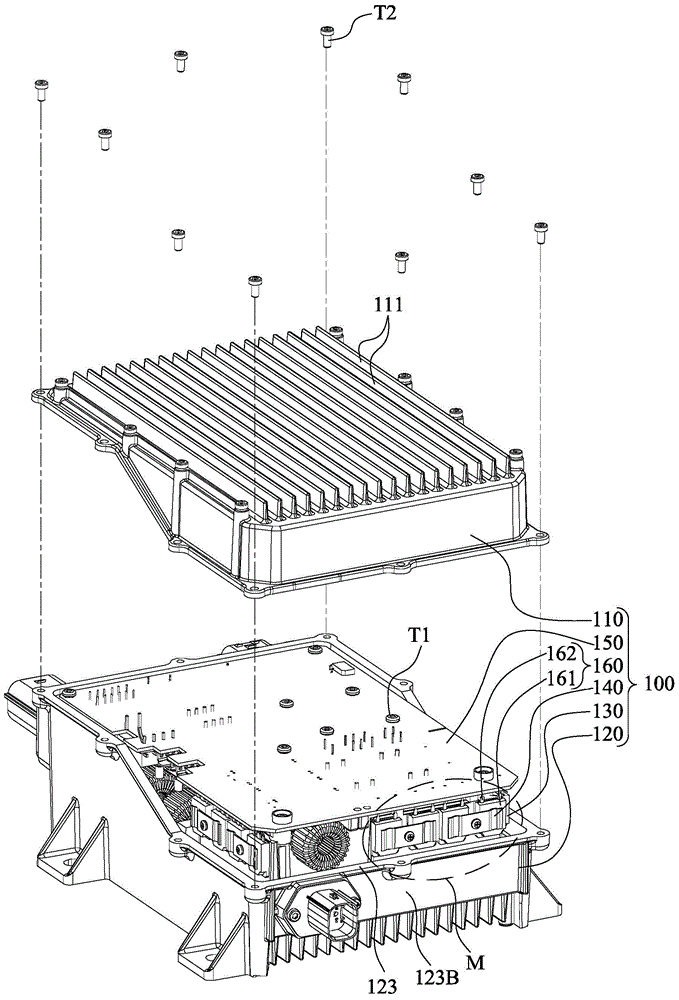

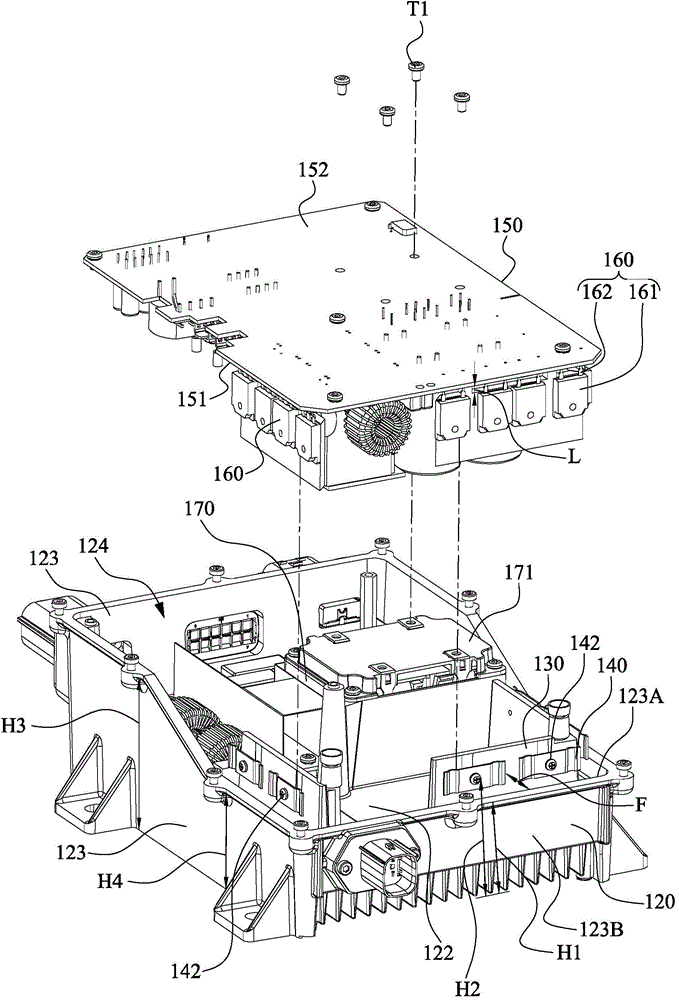

[0056] figure 1 A combined diagram of the electronic device 100 according to the first embodiment of the present invention is shown. figure 2 draw figure 1 partial exploded view. Such as figure 1 and figure 2 shown. An electronic device 100 includes a bottom case 120 , a heat dissipation component 130 , an elastic clip 140 , a wiring board 150 and at least one electronic component 160 (such as a transistor). The heat dissipation assembly 130 is located on the bottom case 120 . The elastic clip 140 is partially installed on the heat dissipation component 130 . Each electronic component 160 includes a body 161 and a plurality of pins 162 . Pins of the electronic component 160 are electrically connected to the wiring board 150 , and the body is clamped between the heat dissipation component 130 and the elastic clip 140 .

[0057] In this way, in the above-mentioned structure, the electronic components and the heat dissipation components are tightly bonded by the elastic...

no. 2 approach

[0072] Figure 5A A perspective view of the insulating pillar 180 according to the second embodiment of the present invention is shown. Figure 5B A cross-sectional exploded view of the wiring board 150 , the insulating support 180 and the heat dissipation component 130 is shown according to the second embodiment of the present invention. The insulating pillar 180 of the second embodiment can be used in the first embodiment. Such as Figure 5BIn order to maintain a fixed connection and electrical insulation between the wiring board 150 and the bottom case 120 , at least one insulating pillar 180 is further included between the wiring board 150 and the bottom case 120 . The insulating pillar 180 connects the heat dissipation component 130 and the distribution board 150 , physically fixes the heat dissipation component 130 and the distribution board 150 , and electrically insulates the heat dissipation component 130 and the distribution board 150 .

[0073] More specifically,...

no. 3 approach

[0077] Figure 6A An exploded view of the electronic device 101 according to the third embodiment of the present invention is shown. Figure 6B A combination diagram of the elastic clip 240 and the heat dissipation component 230 according to the third embodiment of the present invention is shown. Such as Figure 6A As shown, the electronic device 101 of the third embodiment is substantially the same as the electronic device 100 of the first embodiment, except that the appearance of the elastic clip 240 and the heat dissipation assembly 230 of the third embodiment are compared with those of the elastic clip 140 and the first embodiment. The appearance of the cooling assembly 130 is different. Specifically, the heat dissipation assembly 230 is an independent object, and is detachably assembled to the bottom case 120 . The heat dissipation assembly 230 includes two partial features, namely a heat dissipation block 231 and a base 232 . The heat dissipation block 231 of the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com