Novel electronic detonator control module structure and special production tool and method thereof

A technology of electronic detonators and control modules, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as instability, low production efficiency, and inability to protect electronic detonator control modules, so as to improve safety and reliability, The use effect is ideal, the effect of improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

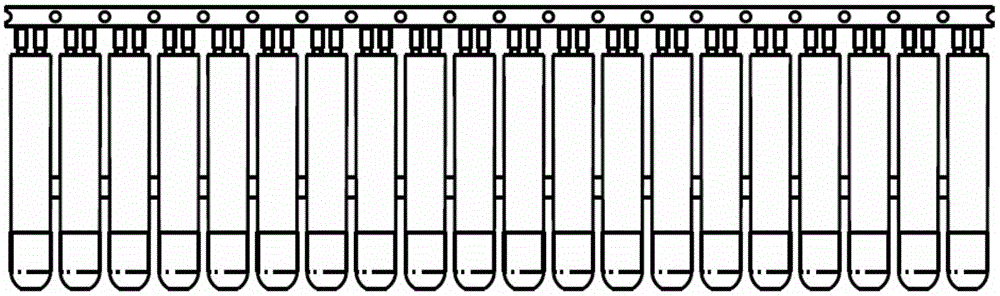

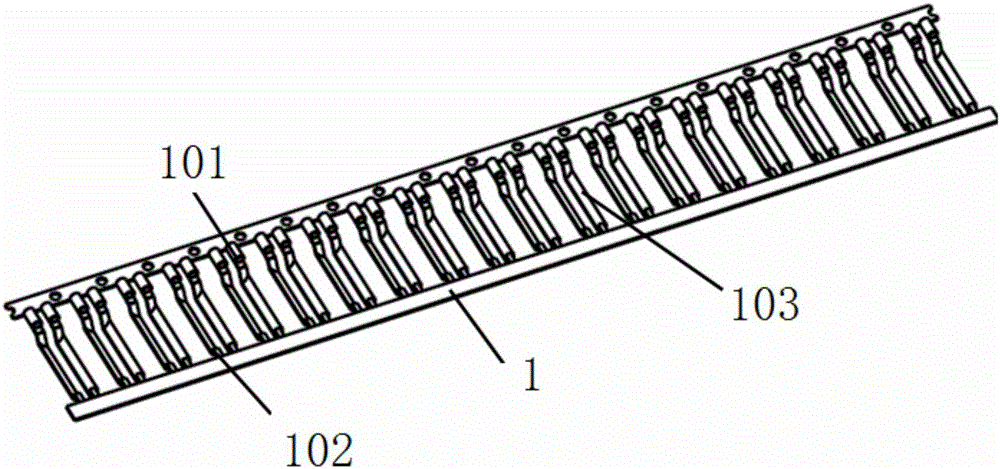

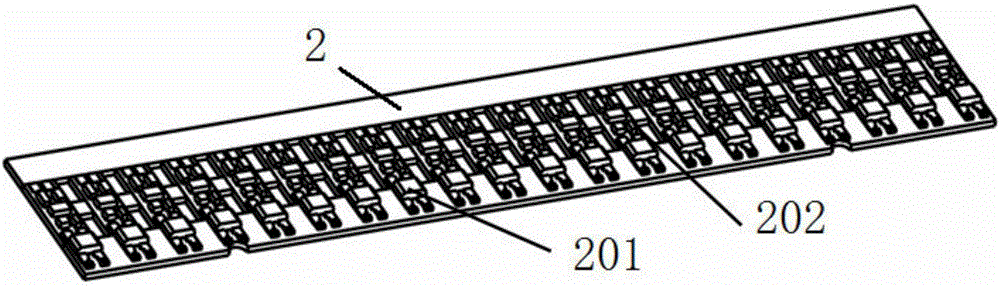

[0038] Embodiment of the present invention: a novel electronic detonator control module structure, including a capacitor bracket 1, an electronic detonator control module 2 and an energy storage capacitor 5, the middle part of the capacitor bracket 1 is a capacitor support part 103, and the front end of the capacitor support part 103 is a connection The foot wire terminal part 101, the end is a pad 102, and the end of the pad is a connecting piece 104; the composition of the electronic detonator control module 2 includes a drug head 201 and a circuit board 202 capacitor support pad 203, and an energy storage capacitor pin pad 204; The welding pad 102 of the capacitor bracket 1 is welded to the circuit board 202 of the electronic detonator control module 2; the energy storage capacitor 5 is located on the capacitor support 103 of the capacitor bracket 1, and the pin of the energy storage capacitor 5 is welded to the pad of the circuit board 202 ; In addition, there is a sealant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com