Al-Si-Nd rare-earth cast aluminum alloy and preparation method thereof

A casting aluminum alloy, al-si-nd technology, applied in the field of aluminum-silicon alloy, can solve the problems that the influence of Al-Si casting aluminum alloy has not been reported, and achieve the effect of no three wastes pollution, simple process and improved shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

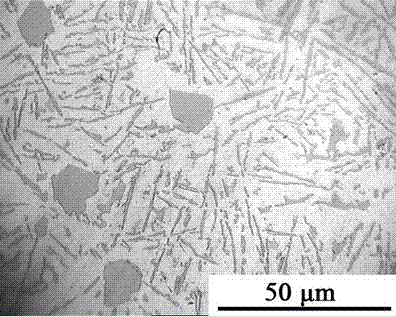

[0014] Implementation Example 1: First, add Al-10Si (mass fraction) alloy into a graphite crucible, and melt the alloy in a resistance furnace at a melting temperature of 760°C. After the metal is completely melted, keep it warm for 20 minutes, add a slag remover, and stir. Remove slag, and then add hexachloroethane wrapped in aluminum foil for degassing and refining. After standing still, cast it into a metal mold to obtain an Al-Si alloy ingot, and the casting temperature is 710°C.

Embodiment 2

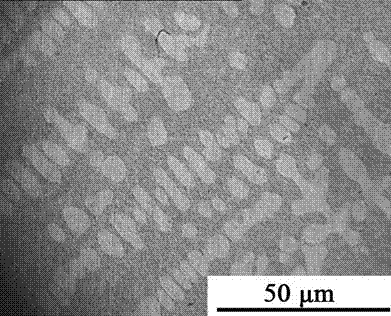

[0015] Implementation example 2: Al-11Si alloy is added to a graphite crucible, heated in a resistance furnace to melt, and rare earth Nd particles with an average diameter of 20um are added, wherein the rare earth element Nd accounts for 0.1% of the total weight of the alloy. The above alloy melt was kept at 760° C. for 10 minutes and then stirred for 3 minutes at a stirring speed of 40 rpm, and then kept for 20 minutes. Finally, the above alloy melt was cast and sampled when the melt temperature dropped to 700°C after degassing and refining.

Embodiment 3

[0016] Implementation example 3: Al-12Si alloy is added to a graphite crucible, heated in a resistance furnace until melted, and rare earth Nd particles with an average diameter of 40um are added, wherein the rare earth element Nd accounts for 0.2% of the total weight of the alloy. The above alloy melt was kept at 730° C. for 15 minutes and then stirred for 5 minutes at a stirring speed of 50 rpm, and then kept for 15 minutes. Finally, the above alloy melt was cast and sampled when the melt temperature dropped to 710°C after degassing and refining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com