Glasses leg and its procesing method

A technology of spectacle feet and temples, which is applied in the direction of glasses/goggles, special patterns, special decorative structures, etc., can solve the problems that can only be displayed on the surface, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The processing and manufacture of spectacle legs comprises the following steps:

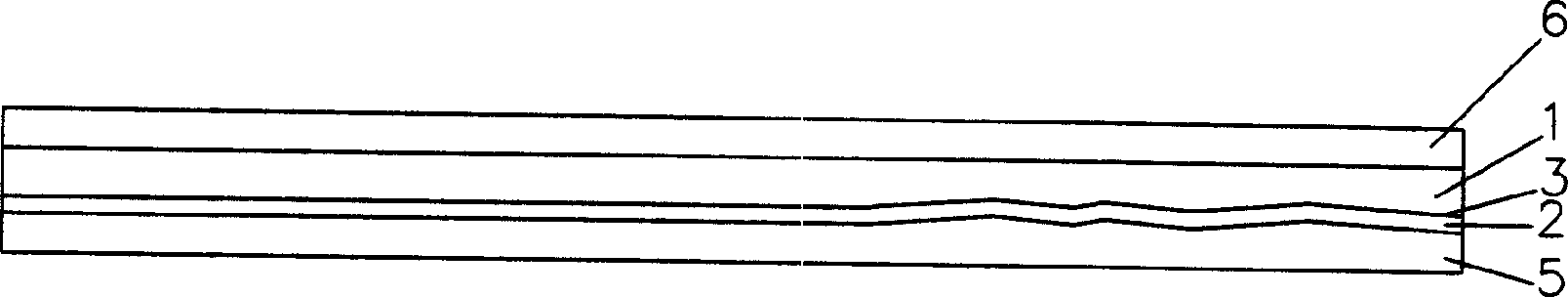

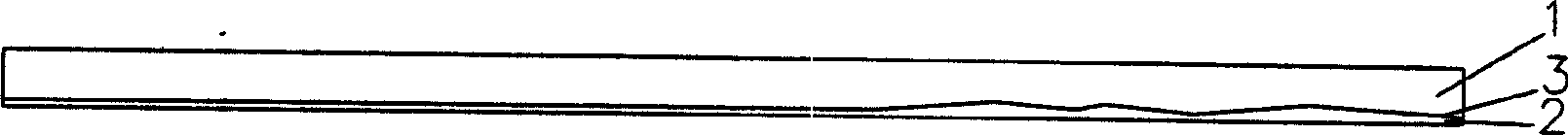

[0026] (1) Select a cellulose acetate rubber sheet, which is composed of a transparent layer 2 and an opaque layer 1, and has a joint surface 3.

[0027] (2), Die-cutting: Die-cutting according to the shape of the temples;

[0028] (3) Heating the die-cut rubber sheet to about 80 degrees Celsius to soften it;

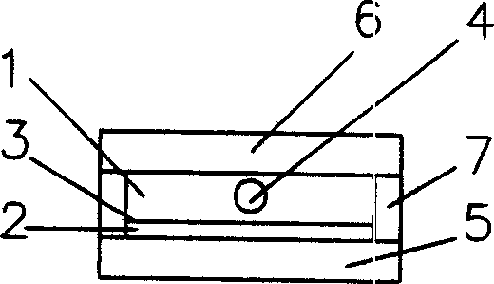

[0029] (4), clamp the softened spectacle pins with a clamping device and drive into the copper needle 4 from one end, the copper needle 4 is in the opaque layer 1, the clamping device includes clamps 7 on both sides, the upper pressing plate 6 and the lower template 5, Wherein the template 5 is engraved with a pattern, and after the 4 steps of injecting copper needles into the temples of the glasses are completed, the outer surface of the transparent layer 2 which contacts the template 5 has a corresponding pattern, and its internal layered structure has also undergon...

Embodiment 2

[0033] Embodiment 2: The processing and manufacture of spectacle legs comprises the following steps:

[0034] (1), choose cellulose acetate rubber sheet such as Figure 4 As shown, it is composed of upper transparent layer 10, pearl powder layer 8 and lower transparent layer 9;

[0035] (2), Die-cutting: Die-cutting according to the shape of the temples;

[0036] (3) Heating the die-cut rubber sheet to about 80 degrees Celsius to soften it;

[0037] (4), clamp the softened spectacle pins with clamping device and drive into copper needle 4 from one end, clamping device comprises clamp 7 on both sides, pressing plate 6 on the top and template 5 below, wherein template 5 is engraved with pattern, in pair After the 4 steps of inserting copper needles into the spectacle feet, the lower transparent layer 9 in contact with the template 5 has a corresponding pattern on the outside, and the pearl powder layer 8 inside it has also undergone corresponding changes;

[0038] (5) Flatten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com