Method for producing benzene arenes from coarse benzene

A technology for benzene-based aromatics and crude benzene, applied in the field of aromatics, can solve the problems of difficult long-term operation, unstable crude benzene, easy polymerization, coking, etc., and achieve the effects of strong adaptability, long continuous operation period and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

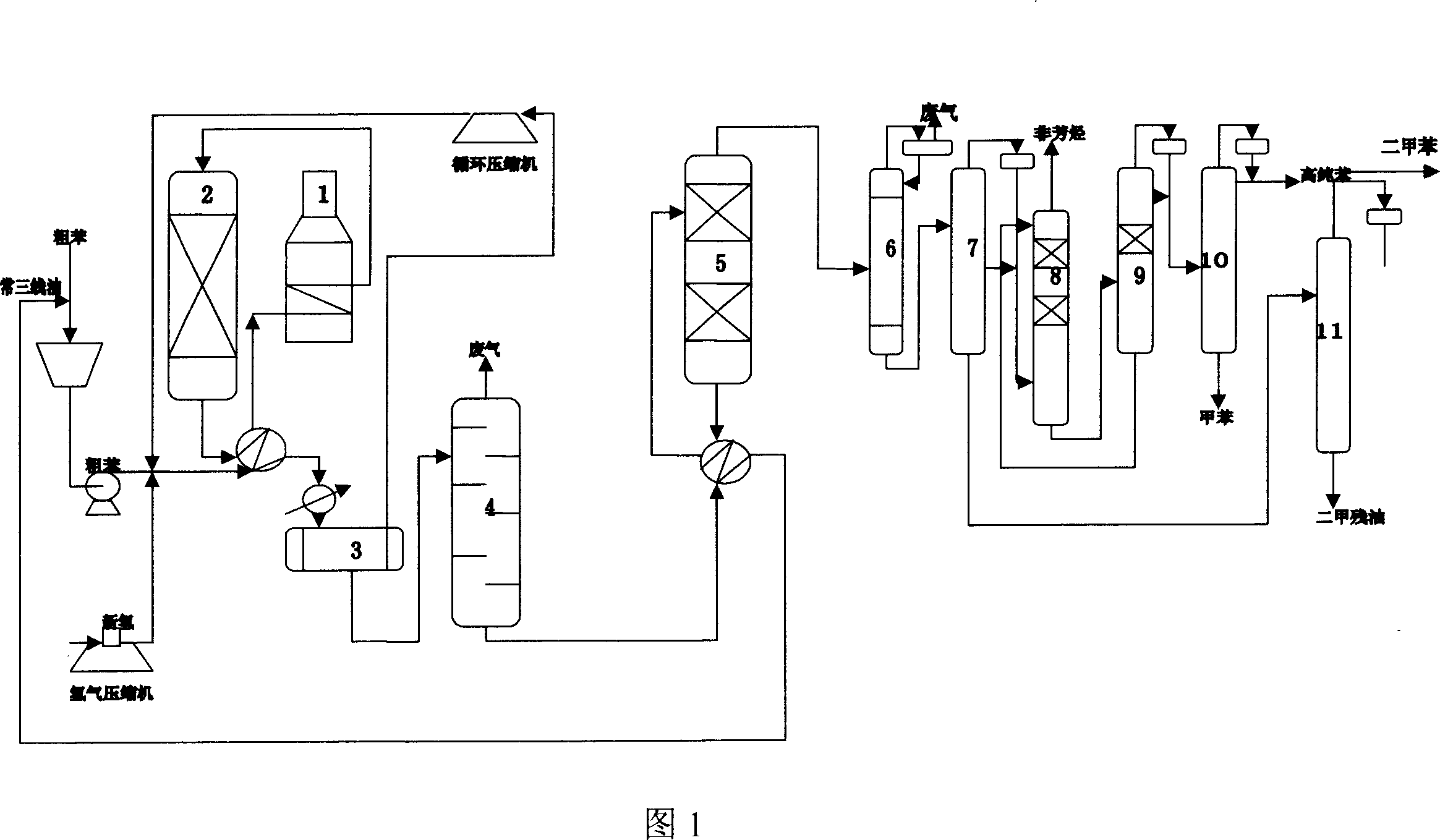

Image

Examples

Embodiment 1

[0025] Raw material 1 is a mixture of crude benzene and normal third-line oil in a weight ratio of 1:9, and its properties are shown in Table 1. After raw material 1 is mixed with hydrogen, it enters the hydrogenation test device. The reaction conditions are shown in Table 2. The catalyst is a molybdenum, cobalt, and phosphorus hydrogenation catalyst. The gas-liquid mixture discharged from the hydrogenation reactor enters the gas-liquid separator. The liquid phase is sent to the gas stripping product tank, the liquid product is collected after steam stripping, and the liquid product enters the fractionation tower. The normal third-line oil separated at the bottom of the fractionation tower is pumped into the crude benzene feedstock inlet for recycling. The distillate separated at the top of the fractionation tower is called hydrogenated oil. The properties and group composition of the hydrogenated oil are shown in Table 2. . The hydrogenated oil is pre-distilled to separate heavy ...

Embodiment 2

[0027] Raw material 2 is a mixture of crude benzene and normal third-line oil in a weight ratio of 2:1. The properties are shown in Table 1. The hydrogenation reaction conditions, the properties and group composition of the hydrogenated oil are shown in Table 2. Other reaction conditions and reaction steps are the same as in Example 1. Product properties are shown in Table 3.

Embodiment 3

[0029] Raw material 3 is a mixture of crude benzene and normal third-line oil in a weight ratio of 9:1. The properties are shown in Table 1. The hydrogenation reaction conditions, the properties and group composition of the hydrogenated oil are shown in Table 2. Other reaction conditions and reaction steps are the same as in Example 1. Product properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com