Ultra-thick hard alloy, and preparation method and application thereof

A cemented carbide and raw material technology, applied in the field of powder metallurgy, can solve the problems of polycrystalline, cobalt pool, and undisclosed drying process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

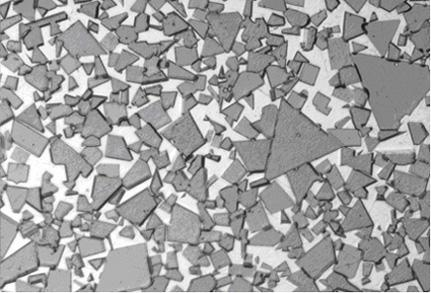

[0072] (1) Pretreatment: re-carbonize the WC raw material at a high temperature of 2100°C and above, and the carbonization time is 1-2 hours; the WC powder after high-temperature carbonization is subjected to multi-stage screening by ultrasonic oscillation, and the ultrasonic frequency is 20-20 30KHz, WC powder is classified into four grade areas of +60, 60-160, 160-250, -250 mesh

[0073] (2) Ingredients: 10.2% Co powder, the rest WC powder.

[0074] (3) Wet grinding: use alcohol as the wet grinding medium, the ball-to-material ratio is 3:1, the liquid-solid ratio is 300ml / Kg, and the paraffin wax accounting for 2.2% of the raw materials is poured in the form of molten liquid 0.3.hr before the raw materials are added Into the ball mill, the total wet grinding time: 16 hours;

[0075] (4) Spray drying: The slurry obtained after wet grinding is sent to the spray drying tower to obtain the mixture; the process conditions of spray drying are:

Embodiment 2

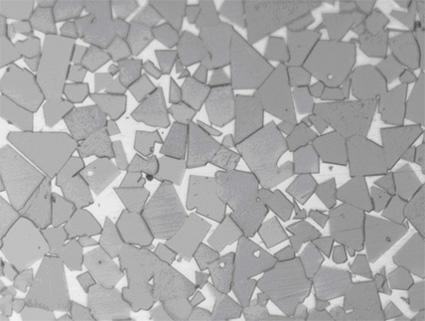

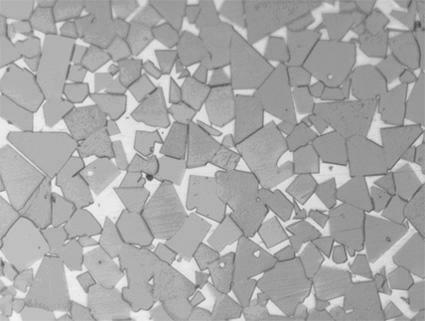

[0094] The process parameters of each step are shown in Table 2. Through the same steps as in Example 1, the obtained ultra-coarse cemented carbide rock drilling tool has a transverse fracture strength of 3200 Mpa, a hardness of 86.2HRA, a coercive force of 3.1KA / m, and a porosity of The degree is A02, B00, C00, and the average grain size of WC is 5.0-6.0μm.

Embodiment 3

[0096] The process parameters of each step are shown in Table 2. Through the same steps as in Example 1, the obtained ultra-coarse cemented carbide rock drilling tool has a transverse fracture strength of 3100 Mpa, a hardness of 86.3HRA, a coercive force of 3.3KA / m, and a porosity of The degree is A02, B00, C00, and the average grain size of WC is 5.0-6.0μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com